Adjustable vacuum chuck device

A vacuum suction cup and adjustable technology, which is applied to manual conveying devices, transportation and packaging, etc., can solve the problems of lens damage, optical lenses are easily broken, etc., and achieve the effect of easy processing and application and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

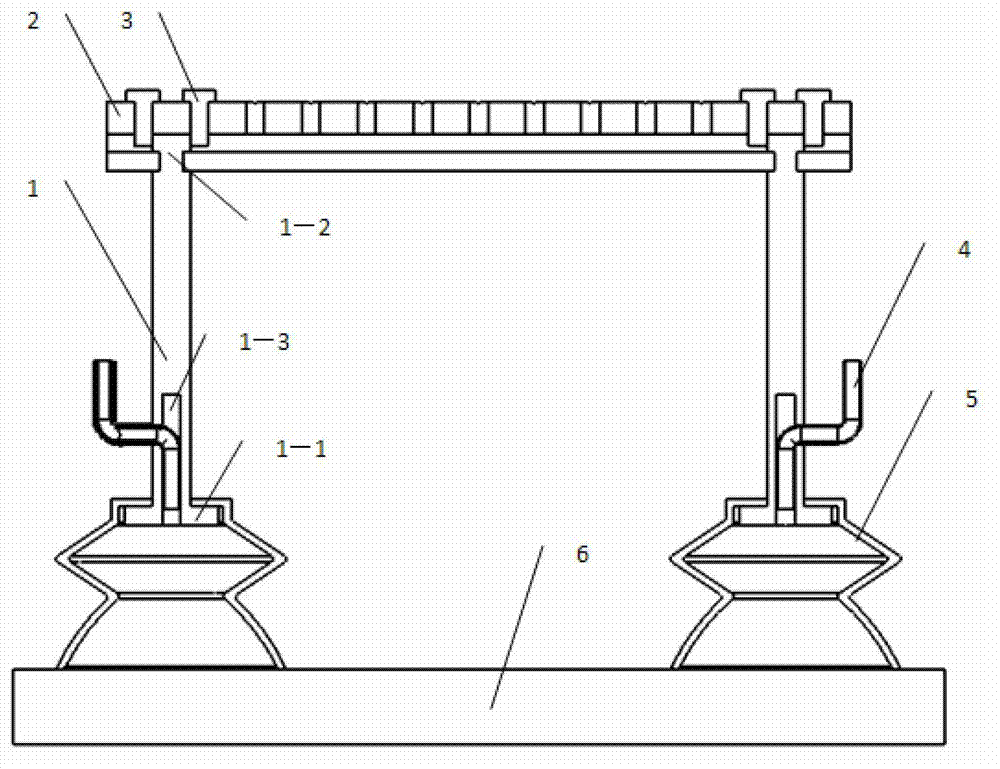

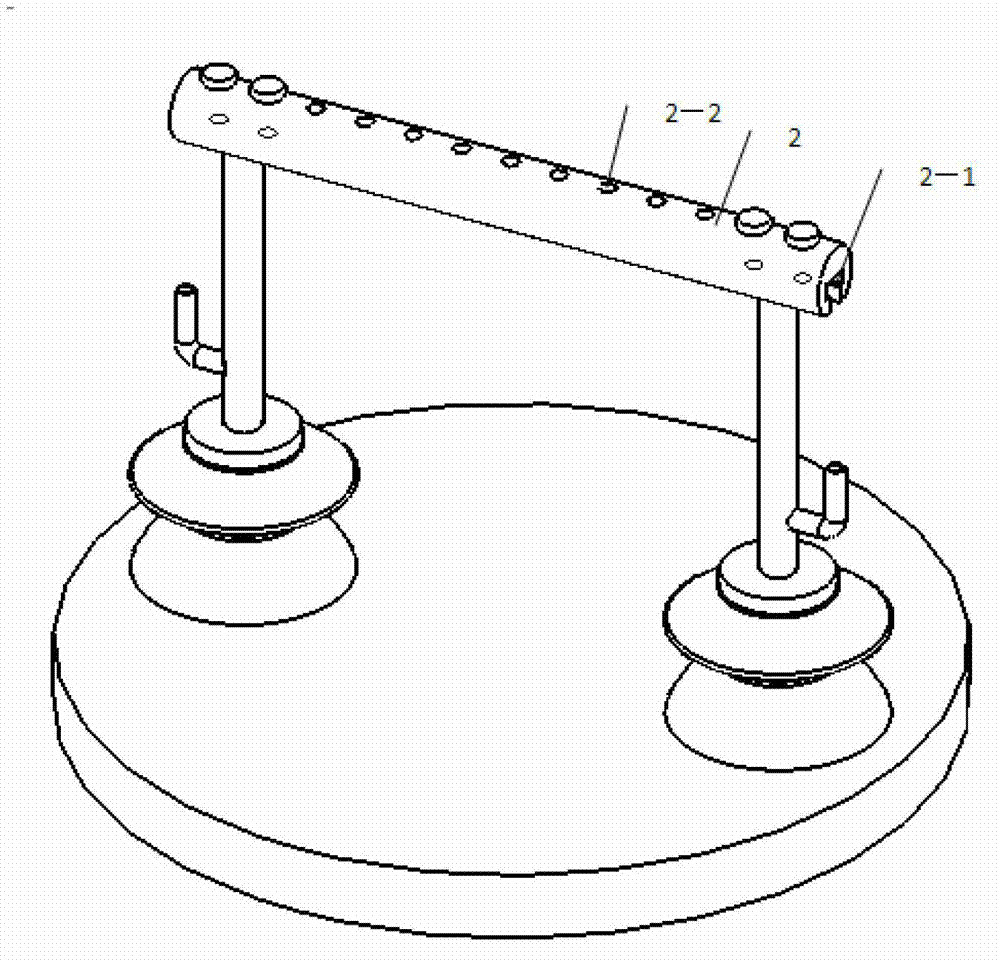

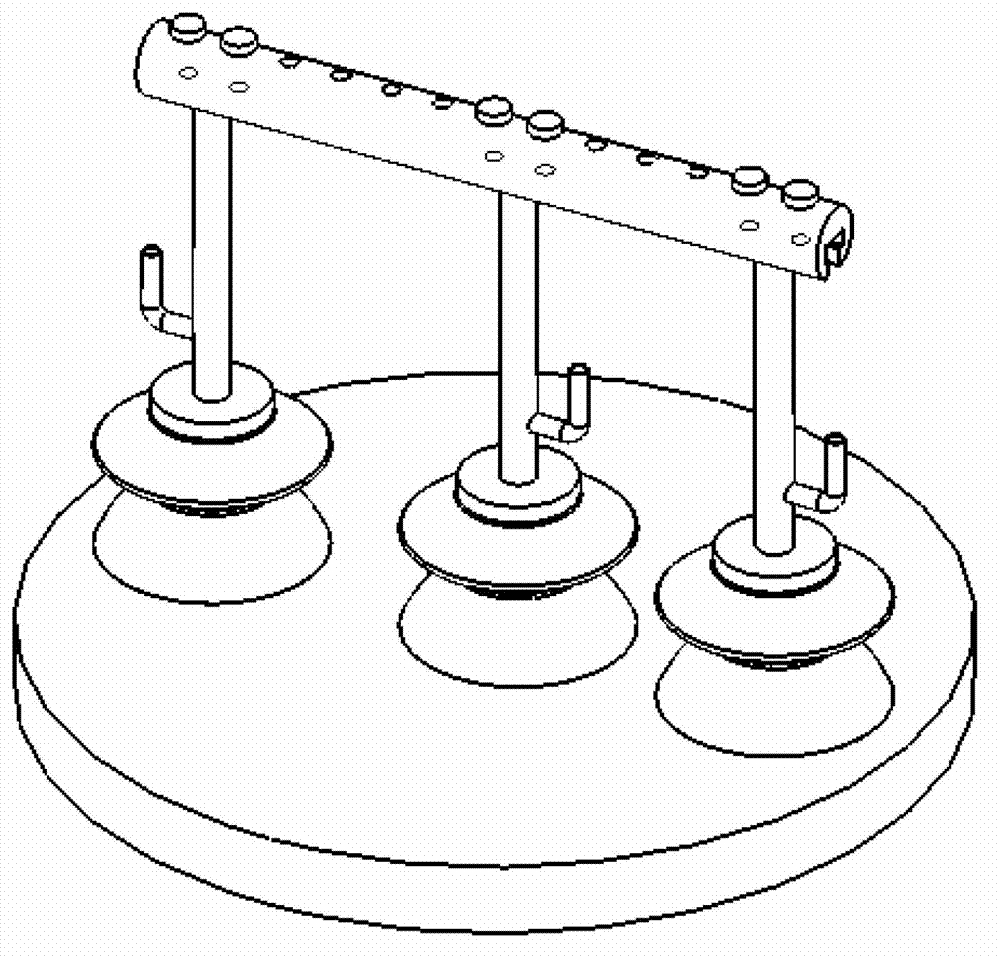

[0020] The present invention is an adjustable vacuum sucker device, which comprises a column 1 , a cross bar 2 , a positioning screw 3 , a vacuum suction pipe 4 and a suction nozzle 5 . The upper end of the column 1 has a sliding pin 1-2 to drive the column 1 to slide in the T-shaped groove 2-1 of the cross bar 2, and the lower end has a suction nozzle joint 1-1 and a vacuum suction pipe groove 1-3, and the vacuum suction pipe 4 passes through the vacuum The suction pipe groove 1-3 is bonded and sealed therein, the suction nozzle 5 is set on the suction nozzle joint 1-1, the two are closely matched, and the exterior is glued and sealed; the positioning screw 3 positions the column 1 in the cross bar 2. Adjust the spacing of the column 1 according to the size of the caliber of the optical lens 6, attach the edge of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com