Cross-linkable grafted polyethylene composition, cross-linked grafted polyethylene product, preparation method and product

A technology for cross-linking grafted polyethylene, which is applied in the fields of cross-linked grafted polyethylene compositions and cross-linked grafted polyethylene products, can solve problems such as short scorch time, and achieve good processing application and safe processing Window, Favorable Effects of Preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the cross-linked grafted polyethylene product of the present invention, comprising: (1) mixing polyethylene, cross-linking agent, cross-linking auxiliary agent, stabilizer, processing improver, antioxidant and lubricating The agent is mixed evenly, and melt blending is carried out at 140-150°C to obtain a cross-linkable grafted polyethylene composition with a gel content of 0% by weight; wherein, the polyethylene is melted at 190°C under a load of 2.16kg The index is more than 30g / 10min; (2) the cross-linkable grafted polyethylene composition obtained in step (1) is molded under processing conditions, and cross-linked grafted polyethylene products are obtained through cross-linking and grafting reactions; Wherein, the processing conditions include: the processing temperature is 200-210° C., and the scorch time at the processing temperature is 2.8 min or more.

[0038] Preferably, the polyethylene has a melt ind...

Embodiment 1

[0068] (1) 100 parts by weight of polyethylene (2650), 0.8 parts by weight of 2,5-dimethyl-2,5-di(tert-butylperoxy)-3-hexyne, 0.4 parts by weight of TAIC, 0.1 parts by weight of tris (2,2,6,6-tetramethylpiperidinyl nitroxide radical) ester and 0.5 parts by weight of maleic anhydride, and 0.1 parts by weight of antioxidant 1010 and 0.1 parts by weight of Antioxidant 168, the stearic acid of 0.2 parts by weight, put into the high-speed mixer and carry out high-speed mixing 5min to uniform, then add in the mixer and melt and blend at 150 ℃ to be cross-linkable grafted polyethylene composition, mixing The mill speed is 50rpm; the gel content of the cross-linkable grafted polyethylene composition is determined to be 0% by weight;

[0069] (2) Put the cross-linkable grafted polyethylene composition into a banbury extruder at 200° C. for molding processing to obtain a cross-linked grafted polyethylene product. See Table 2 for the determination of the scorch time.

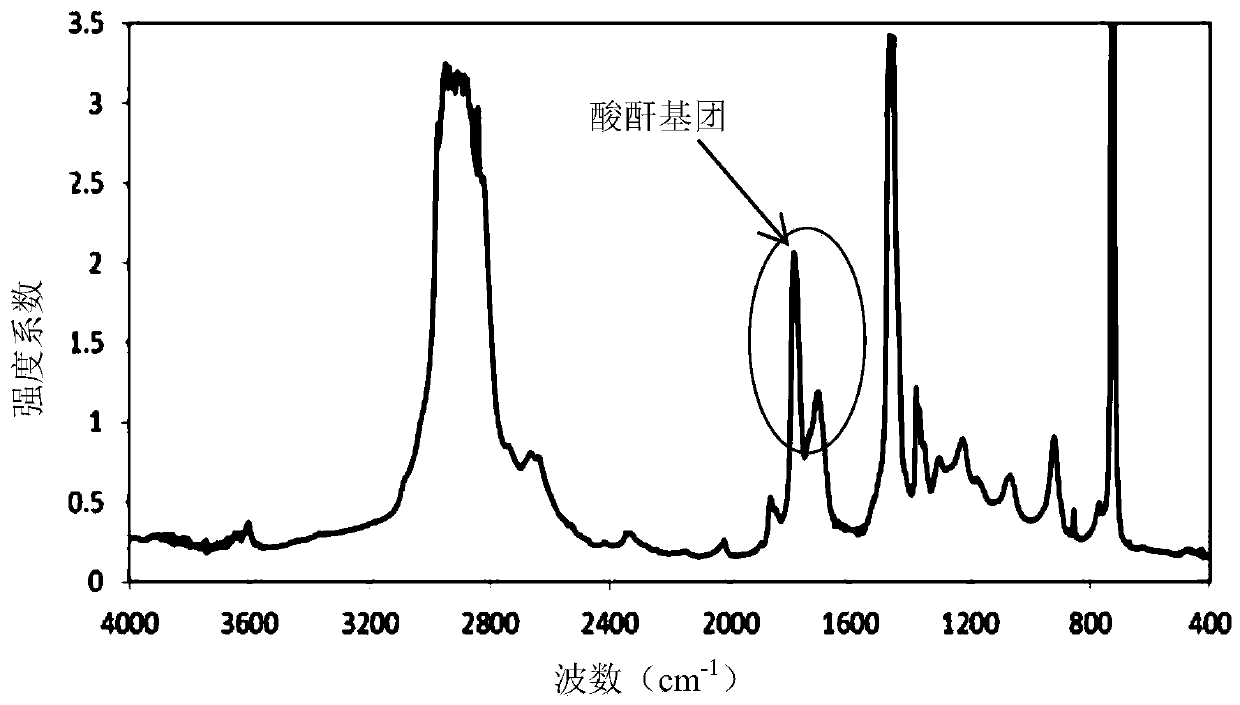

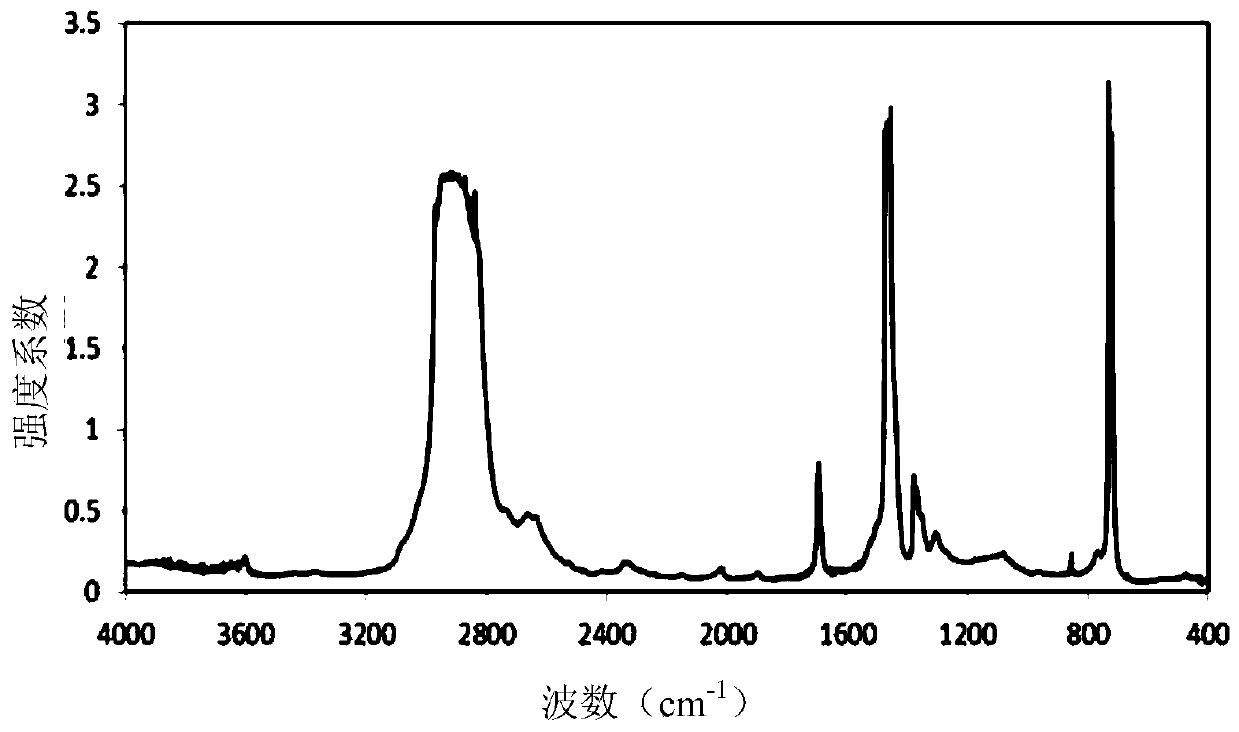

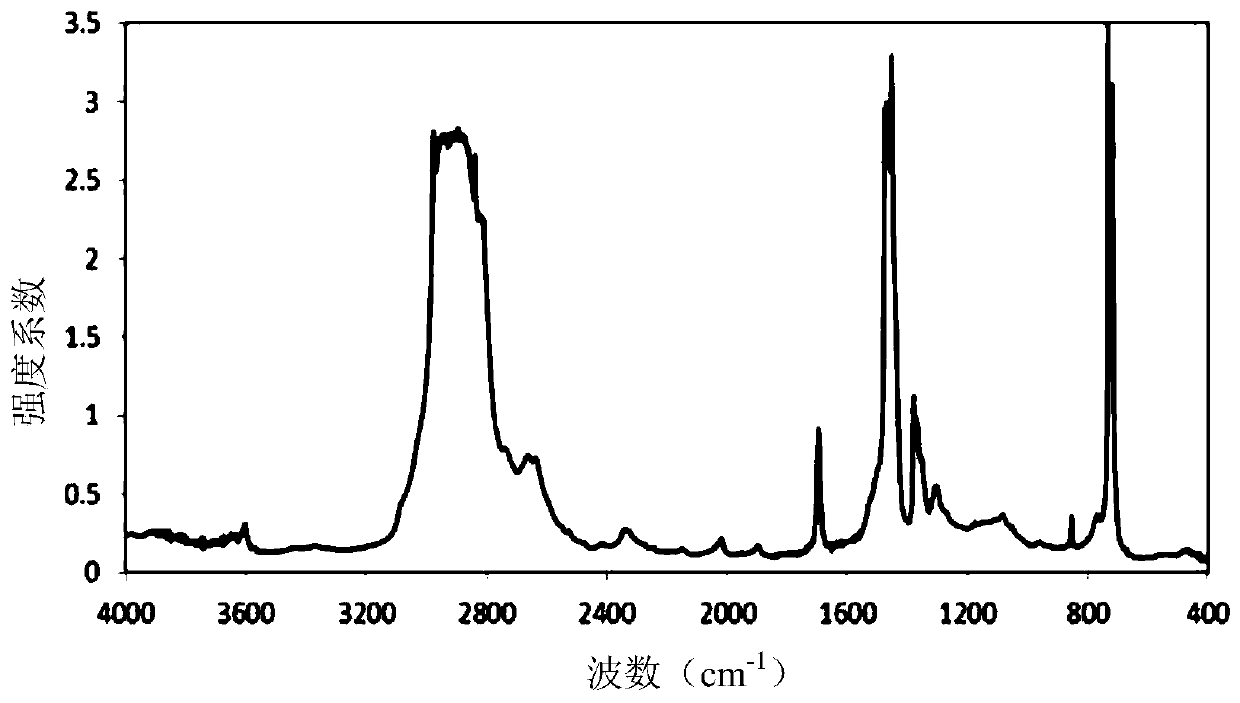

[0070] The cross-...

Embodiment 2

[0073] (1) 100 parts by weight of polyethylene (2650), 1.5 parts by weight of dibenzoyl peroxide, 0.6 parts by weight of triallyl cyanurate, 0.15 parts by weight of nitroxide free radical piperidinol and 2 parts by weight of Part of maleic anhydride, and the antioxidant 1010 of 0.1 weight part and the antioxidant 168 of 0.1 weight part, the stearic acid of 0.2 weight part, put into high-speed mixer and carry out high-speed mixing 5min to evenly, then add kneader Melting and blending at 140° C. to form a cross-linkable grafted polyethylene composition, the mixer speed is 50 rpm; the measured gel content of the cross-linked grafted polyethylene composition is 0% by weight;

[0074] (2) Put the cross-linkable grafted polyethylene composition into a banbury extruder at 210° C. for molding processing to obtain a cross-linked grafted polyethylene product. See Table 2 for the determination of the scorch time.

[0075] The cross-linked grafted polyethylene product is subjected to xyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com