HfC/C ceramic precursor polymer and preparation method thereof

A technology of polymers and compounds, applied in the field of polymer materials, can solve problems such as structural characterization of side reactions that cannot be ruled out, few researches on the conversion of hafnium carbide ceramics, and complex reaction processes, etc., to achieve low oxygen content, reduce weight loss, and ensure solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 2.0mmol of hafnium tetra-n-propoxide, 2.0mmol of tetrasalicylidene-3,3'-diaminobenzidine, and 20mL of N-methylpyrrolidone into a 100mL single-necked flask, and stir at 25°C for ligand exchange polymerization After reacting for 4 hours, the reaction mixture was added to 120 mL of methanol, and a yellow solid was precipitated. After filtration, the precursor polymer represented by formula I provided by the present invention was obtained.

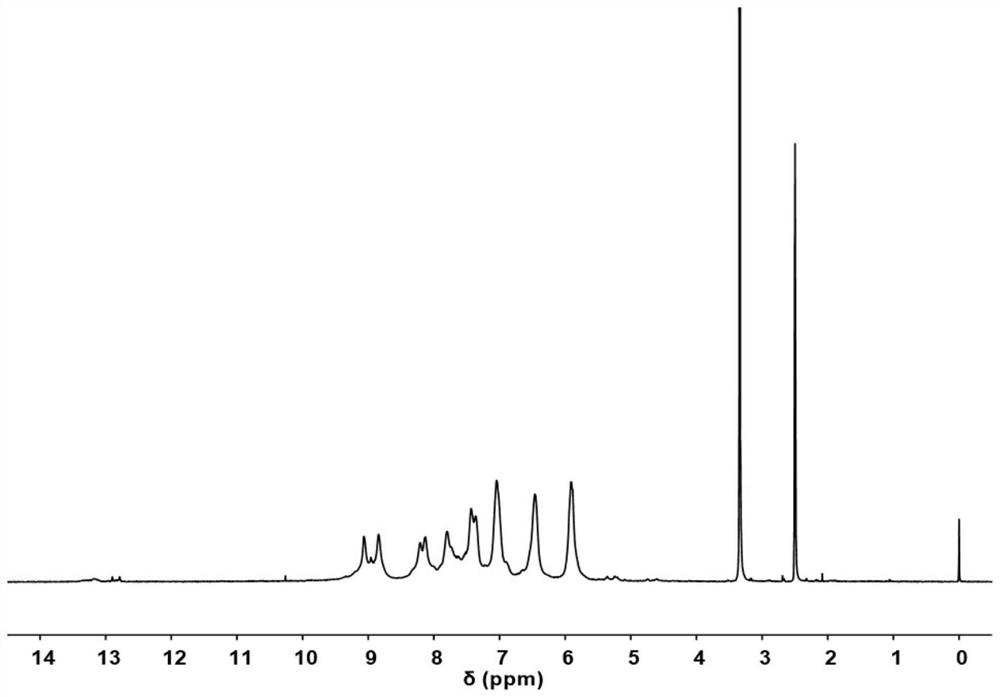

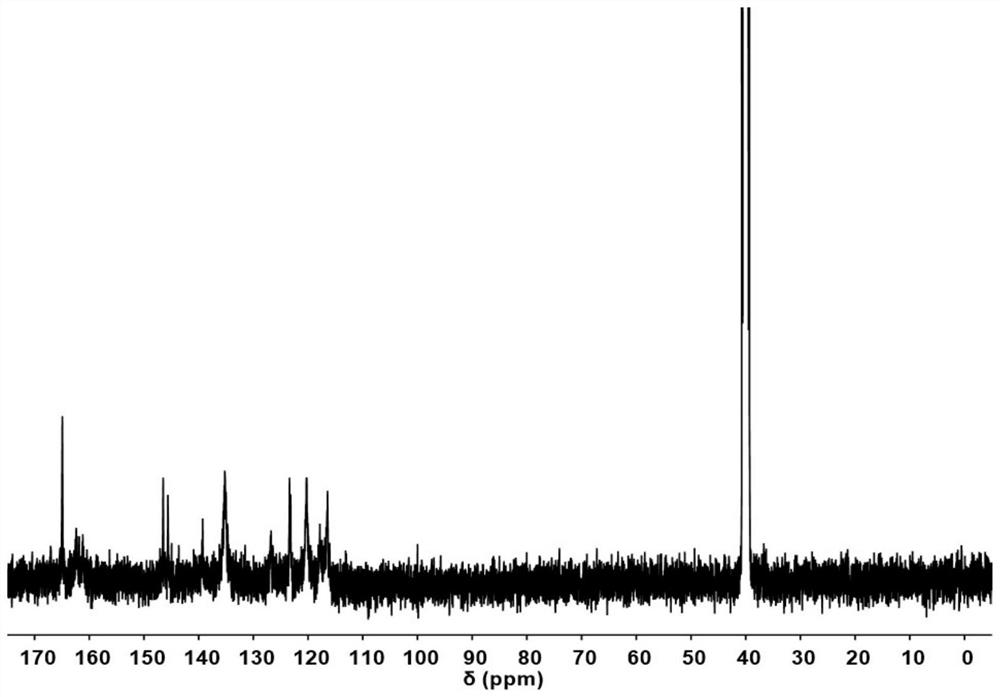

[0056] Its H NMR and C NMR spectra are as follows figure 1 with figure 2 As can be seen from the figure, the product has a correct structure and is the target product.

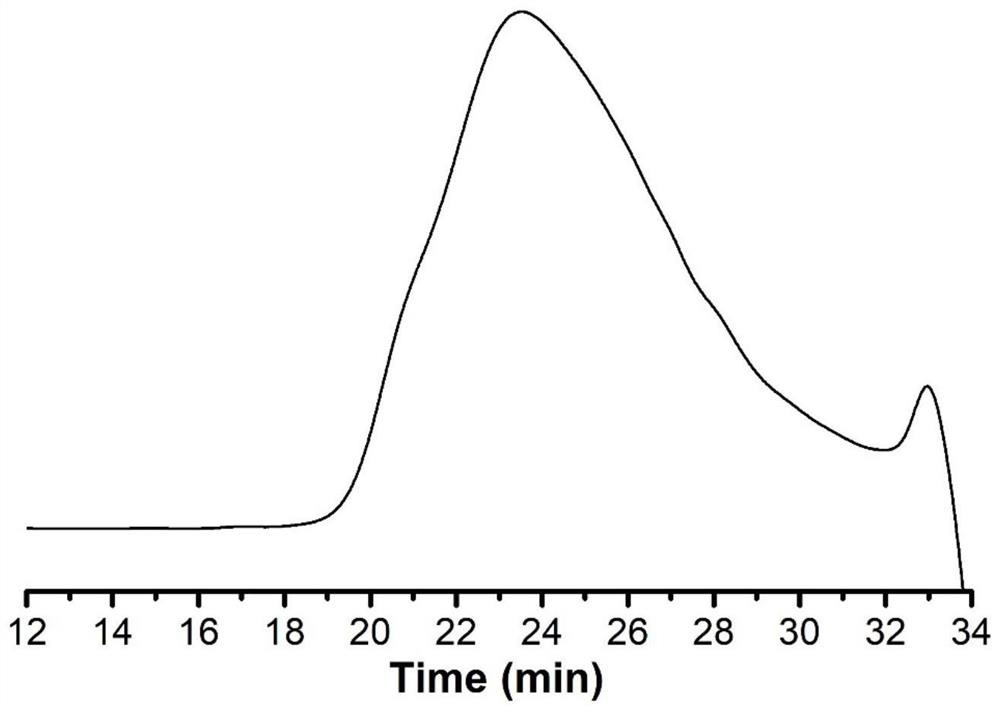

[0057] GPC characterization number average molecular weight is 3750 (n is 4.7 among the corresponding formula I), and GPC spectrogram is as image 3 shown.

[0058] The precursor polymer was pyrolyzed at 1600°C for 2 hours in an argon atmosphere to obtain a black ceramic product with a ceramic yield of 59.4%. XRD and Raman spectrum analysis showed that the produ...

Embodiment 2

[0062] 100mL one-necked flask, add 1.0mmol of hafnium tetra-n-propoxide and 1.0mmol of hafnium tetraisopropoxide, 2.0mmol of tetrasalicylidene-3,3'-diaminobenzidine, 10mL of N-methylpyrrolidone and 10 mL of tetrahydrofuran was stirred at 25°C for ligand exchange polymerization for 24 hours, then the reaction mixture was added to 120 mL of methanol, a yellow solid was precipitated, and the precursor polymer represented by formula I provided by the present invention was obtained after filtration.

[0063] GPC characterization number average molecular weight is 4100 (n is 5.1 in the corresponding formula I).

[0064] The precursor polymer was pyrolyzed at 1600°C for 2 hours in an argon atmosphere to obtain a black ceramic product with a ceramic yield of 61.9%. XRD and Raman spectroscopic analysis showed that the product was HfC / C ceramics.

[0065] The ultra-high temperature performance of the HfC / C ceramic product cannot be detected in a general laboratory because it cannot be m...

Embodiment 3

[0068] In a 100mL one-necked flask, add 2.0mmol of hafnium tetra-n-butoxide and 3.0mmol of tetrasalicylidene-3,3'-diaminobenzidine, 10mL of dimethylformamide and 10mL of tetrahydrofuran, and stir at 40°C Ligand exchange polymerization was carried out for 6 hours, and then the reaction mixture was added to 60 mL of methanol and 60 mL of ethanol, a yellow solid was precipitated, and after filtration, the precursor polymer represented by formula I provided by the present invention was obtained.

[0069] According to GPC, the number average molecular weight is 2460 (n is 3.1 in the corresponding formula I).

[0070] The precursor polymer was pyrolyzed at 1600°C for 2 hours in an argon atmosphere to obtain a black ceramic product with a ceramic yield of 57.3%. XRD and Raman spectroscopic analysis showed that the product was HfC / C ceramics.

[0071] The ultra-high temperature performance of the HfC / C ceramic product cannot be detected in a general laboratory because it cannot be mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com