A heat-insulating insulator insulation shielding cover for electric power

A technology of shielding cover and insulator, applied in the direction of overhead line/cable equipment, coating, etc., can solve the problems of endangering the life safety of operators, breakdown of insulation blanket, cumbersome and other problems, and achieve the improvement of volume resistivity, reduction of bond strength, Guaranteed insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

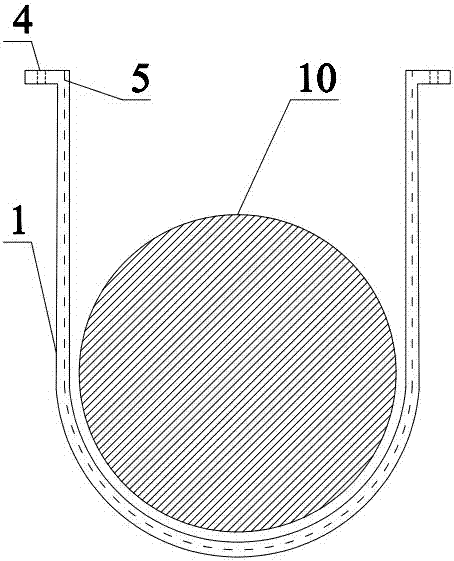

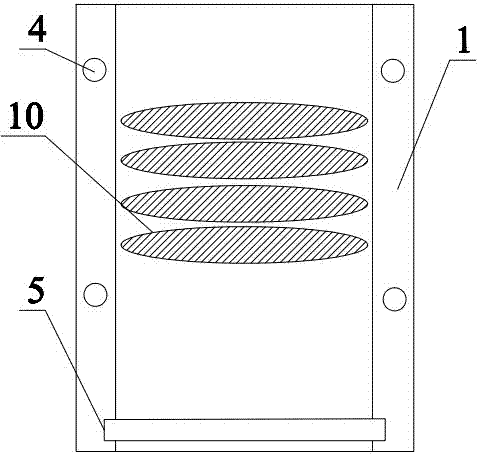

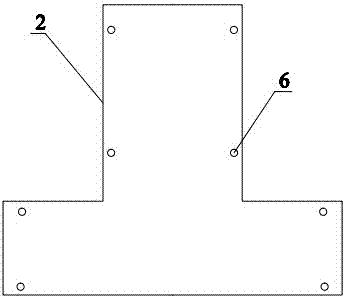

[0033] Such as Figure 1~7As shown, a heat-insulating insulator insulation shield for electric power includes an insulator shield 1, a shield cover plate 2 and a suspension clamp shield 3. The insulator shield 1 is set in a "U" shape, and the insulator shield 1 is two The first fixing hole 4 is set on the edge of the first side, and the bottom inner side of the insulator shield 1 is provided with a base connection groove 5, and the insulator shield 1 is movably connected with the suspension wire clamp shield 3 through the base connection groove 5, and the shield cover plate 2 is set as " T" shape, which is roughly consistent with the shape of the overall installation of the shielding cover, which can fully protect the insulation shielding cover as a whole. The cover plate 2 of the shielding cover is provided with a plurality of second fixing holes 6 corresponding to the first fixing holes 4 , it can be connected with the main body of the insulation shielding cover by using a b...

Embodiment 2

[0044] The structure of embodiment 2 is roughly the same as that of embodiment 1, the difference is:

[0045] Among them, the high temperature and wear-resistant insulating coating is made of the following raw materials in parts by weight: 70 parts of polystyrene resin, 0.8 parts of DL-411 aluminate coupling agent, 20 parts of quartz sand, 5 parts of borax, 2 parts of natural camphor, 20 parts of nano inorganic filler, 55 parts of xylene, 0.7 part of glycidyl methacrylate, 4 parts of polyolefin wax, 2 parts of rosin, 3 parts of chloromethyl ester and 0.5 part of NXZ defoamer.

[0046] The nano-inorganic filler includes nano-silicon nitride powder, nano-silicon carbide powder and nano-zirconium silicate powder, and the weight ratio of nano-silicon nitride powder, nano-silicon carbide powder and nano-zirconium silicate powder is 3.5:3:1.

[0047] The preparation method of the high-temperature-resistant wear-resistant insulating coating comprises the following steps:

[0048] 1)...

Embodiment 3

[0053] The structure of embodiment 3 is roughly the same as that of embodiment 1, the difference is:

[0054] Among them, the high temperature resistant and wear-resistant insulating coating is made of the following raw materials in parts by weight: 60 parts of polystyrene resin, 0.4 part of DL-411 aluminate coupling agent, 16 parts of quartz sand, 3 parts of borax, 0.8 part of natural camphor, 16 parts of nano inorganic filler, 45 parts of xylene, 0.5 part of glycidyl methacrylate, 3 parts of polyolefin wax, 1.2 parts of rosin, 3 parts of chloromethyl ester and 0.5 part of NXZ defoamer.

[0055] The nano-inorganic filler includes nano-silicon nitride powder, nano-silicon carbide powder and nano-zirconium silicate powder, and the weight ratio of nano-silicon nitride powder, nano-silicon carbide powder and nano-zirconium silicate powder is 3.5:1.5:1.

[0056] The preparation method of the high-temperature-resistant wear-resistant insulating coating comprises the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com