A kind of preparation method of charcoal reinforced silicon carbide matrix composite material

A silicon carbide-based, composite material technology, applied in the field of composite material preparation, can solve the problems of insufficient high-temperature strength and wear resistance, large silicon carbide particles, and high free silicon content, and achieve high density, high yield, and short process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

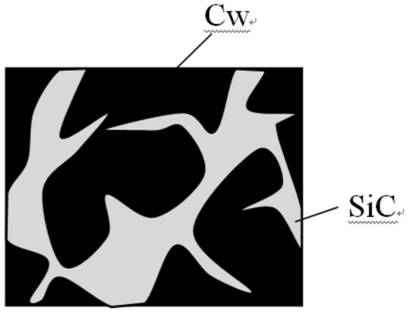

Image

Examples

Embodiment 1

[0030] Choose soft-leaved Chinese fir, and process it into a uniform wooden stick with a length of 60cm and a diameter of 6cm, with a density of 0.6g / cm 3 , no scars on the surface. After dehydration at 130° C. in vacuum for two hours, soak in 20% ethylenediamine aqueous solution for one day, and then dehydrate at 140° C. in vacuum for 2 hours. Carbonize in a vacuum furnace at 900°C for 1 hour. Sand the carbon rod carefully with sandpaper, and blow off the attached carbon powder with compressed air. Obtain the charcoal rod (diameter 4.2cm, long 46cm, density of 1.3g / cm2) of uniform appearance 3) put the charcoal rod in a vacuum impregnation tank, control the vacuum degree ≤0.001MPa, and vacuum impregnate for 3 hours. The impregnating agent in the vacuum impregnation tank consists of: 120 parts of polymethylsilane, 20 parts of 1,5-hexadiene, even 2 parts of nitrogen bisisobutyronitrile; then solidify under nitrogen atmosphere, wherein the curing procedure is: first raise the...

Embodiment 2

[0032] Choose soft-leaved Chinese fir, and process it into a uniform wooden stick with a length of 60cm and a diameter of 6cm, with a density of 0.55g / cm 3 , no scars on the surface. After dehydration at 150° C. in vacuum for 2 hours, soak in 20% ethylenediamine aqueous solution for one day, and then dehydrate at 150° C. in vacuum for 2 hours. Then carbonize in a vacuum furnace at 900°C for 1 hour. Sand the carbon rod carefully with sandpaper, and blow off the attached carbon powder with compressed air. Obtain the charcoal rod (diameter 4cm, long 43cm, density of 1.25g / cm2) of uniform appearance 3 ) put the charcoal rod in a vacuum impregnation tank, control the vacuum degree ≤ 0.001MPa, and vacuum impregnate for 3 hours. The impregnating agent in the vacuum impregnation tank consists of: 90 parts of polymethylsilane, 25 parts of 1,5-hexadiene, even 3 parts of nitrogen bisisobutyronitrile; then solidify under nitrogen atmosphere, wherein the curing procedure is: first raise...

Embodiment 3

[0034] Choose pine wood, process it into a uniform wooden stick with a length of 60cm, a diameter of 6cm, and a density of 0.6g / cm 3 , no scars on the surface. After dehydration at 140° C. in vacuum for 3 hours, soak in 20% ethylenediamine aqueous solution for one day, and then dehydrate at 120° C. in vacuum for 4 hours. Then carbonize in a vacuum furnace at 900°C for 1 hour. Sand the carbon rod carefully with sandpaper, and blow off the attached carbon powder with compressed air. Obtain the charcoal rod (diameter 4cm, long 43cm, density of 1.3g / cm2) of uniform appearance 3 ) put the charcoal rod in a vacuum impregnation tank, control the vacuum degree ≤0.001MPa, and vacuum impregnate for 4 hours. The impregnating agent in the vacuum impregnation tank consists of: 110 parts of polymethylsilane, 30 parts of 1,5-hexadiene, 4 parts of nitrogen diisobutyronitrile; then solidify under a nitrogen atmosphere, wherein the curing procedure is: first raise the temperature to 55°C at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com