Expanded graphite/polyimide-polyether sulfone composite bipolar plate and preparation method thereof

A technology of polyimide and expanded graphite, which is applied in the field of fuel cell preparation, can solve problems such as low bending strength and electrical conductivity, high hydrogen gas transmission rate, and poor comprehensive performance, so as to improve mechanical properties, ease thermal shock, The effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

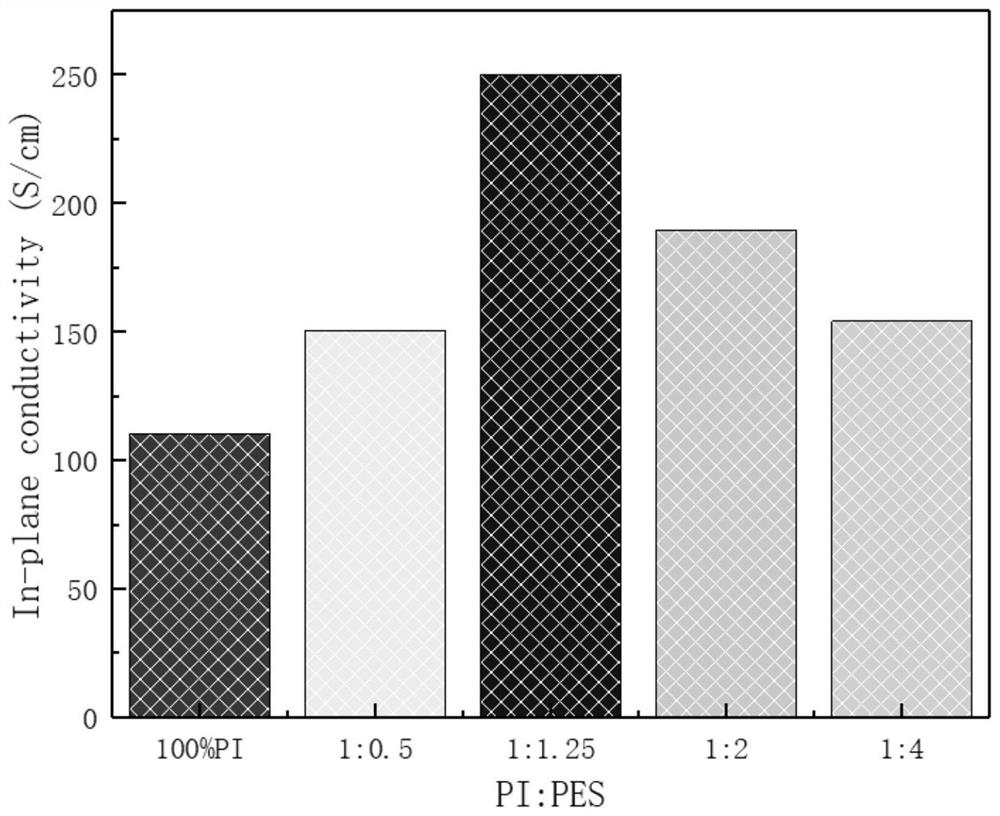

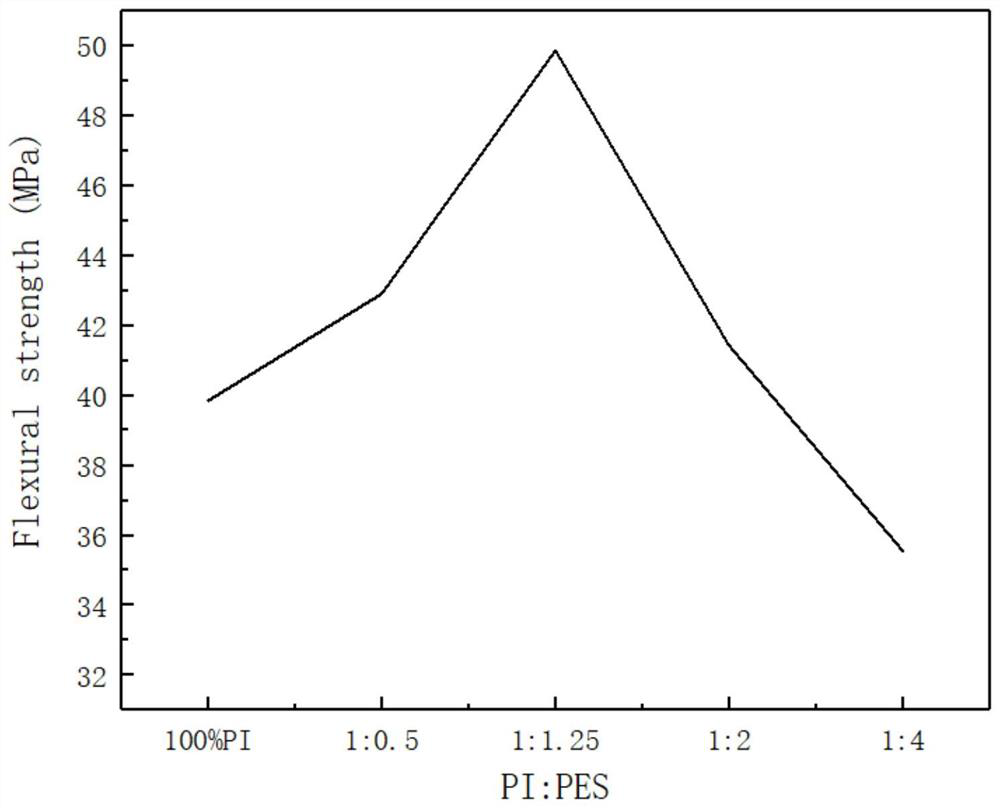

[0046] (1) Preparation of polyimide-polyethersulfone mixed solution

[0047] Weigh a certain mass of polyimide and polyether sulfone and pour it into DMF organic solvent to dissolve. The mass ratio of the total mass of polyimide and polyether sulfone to solvent DMF is 1:10. Polyimide resin and polyether The mass ratio of sulfone resin is 1:1.25, and the mass fraction of polyimide and polyethersulfone resin in the mixture (polyimide, polyethersulfone and expanded graphite) is 40%.

[0048] (2) Configure expanded graphite / polyimide-polyethersulfone mixture

[0049] The expanded graphite is added to the polyimide-polyethersulfone mixed solution, the polyimide-polyethersulfone mixed resin accounts for 40% of the mixed material (solid content), and the expanded graphite accounts for the mixed material (solid content) The quality score of 60%. The two components are mixed according to a certain mass ratio according to the preset plan, and the mixed slurry is ultrasonically treated...

Embodiment 2

[0055] (1) Preparation of polyimide-polyethersulfone mixed solution

[0056] Weigh a certain mass of polyimide and polyethersulfone and pour it into DMF organic solvent to dissolve, the mass ratio of polyimide and polyethersulfone to solvent DMF is 1:10, polyimide resin and polyethersulfone resin The mass ratio of polyimide and polyethersulfone resin is 1:2, and the total mass of polyimide and polyethersulfone resin accounts for 40% of the mass fraction of the mixture (polyimide, polyethersulfone and expanded graphite).

[0057] (2) Configure expanded graphite / polyimide-polyethersulfone mixture

[0058] The expanded graphite is added to the polyimide-polyethersulfone mixed solution, the polyimide-polyethersulfone mixed resin accounts for 40% of the mixed material (solid content), and the expanded graphite accounts for the mixed material (solid content) The quality score of 60%. According to the preset plan, the two components are mixed according to a certain mass ratio, and ...

Embodiment 3

[0064] (1) Preparation of polyimide-polyethersulfone mixed solution

[0065] Weigh a certain mass of polyimide and polyethersulfone and pour it into DMF organic solvent to dissolve, the mass ratio of polyimide and polyethersulfone to solvent DMF is 1:10, polyimide resin and polyethersulfone resin The mass ratio of polyimide and polyethersulfone resin accounts for 40% of the mass fraction of the mixed material (polyimide, polyethersulfone and expanded graphite).

[0066] (2) Configure expanded graphite / polyimide-polyethersulfone mixture

[0067]The expanded graphite is added to the polyimide-polyethersulfone mixed solution, the polyimide-polyethersulfone mixed resin accounts for 40% of the mixed material (solid content), and the expanded graphite accounts for the mixed material (solid content) The quality score of 60%. According to the preset plan, the two components are mixed according to a certain mass ratio, and the mixed slurry is ultrasonically treated for 15 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com