A kind of high-performance environment-friendly composite building ceramic material and preparation method thereof

A high-performance technology for architectural ceramics, applied in the field of ceramic materials, can solve the problems of insufficient environmental protection and insufficient strength to meet the requirements, and achieve the effects of enhancing integrity, increasing strength, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of described ceramic material, comprises the steps:

[0041] The first step is to mix silicon powder, modified graphite powder, silicon carbide, metal Ni powder, silicon nitride powder and additives, add ceramic balls of the same quality to the mixture, put it into a ball mill for 20 hours, and the speed is 300r / min;

[0042] The second step is to put the ball-milled powder into the self-propagating reactor and vacuumize it. When the vacuum in the reactor reaches 10MPa, fill it with high-purity nitrogen to a pressure of 7.5MPa, turn on the electricity and ignite it, and carry out the self-propagating high-temperature synthesis reaction. , the reaction time is controlled at 4-5h;

[0043] The third step is to collect the composite powder after the reaction is over, add sintering aid to the composite powder, carry out ball milling for 10 hours to fully mix the materials, and then carry out vacuum hot-press sintering on the composite powder, and main...

Embodiment 1

[0045] A high-performance environment-friendly composite building ceramic material, made of the following raw materials in parts by weight: 60 parts of silicon powder, 3 parts of silicon carbide, 1 part of metal Ni powder, 9 parts of modified graphite powder, 30 parts of silicon nitride powder, additives 15 parts, 6 parts of sintering aid;

[0046] The ceramic material is made by the following steps:

[0047] The first step is to mix silicon powder, modified graphite powder, silicon carbide, metal Ni powder, silicon nitride powder and additives, add ceramic balls of the same quality to the mixture, put it into a ball mill for 20 hours, and the speed is 300r / min;

[0048] The second step is to put the ball-milled powder into the self-propagating reactor and vacuumize it. When the vacuum in the reactor reaches 10MPa, fill it with high-purity nitrogen to a pressure of 7.5MPa, turn on the electricity and ignite it, and carry out the self-propagating high-temperature synthesis reac...

Embodiment 2

[0051] A high-performance environment-friendly composite building ceramic material is made of the following raw materials in parts by weight: 65 parts of silicon powder, 3.5 parts of silicon carbide, 1.5 parts of metal Ni powder, 10 parts of modified graphite powder, 33 parts of silicon nitride powder, additives 18 parts, 7 parts of sintering aid;

[0052] The ceramic material is made by the following steps:

[0053] The first step is to mix silicon powder, modified graphite powder, silicon carbide, metal Ni powder, silicon nitride powder and additives, add ceramic balls of the same quality to the mixture, put it into a ball mill for 20 hours, and the speed is 300r / min;

[0054] The second step is to put the ball-milled powder into the self-propagating reactor and vacuumize it. When the vacuum in the reactor reaches 10MPa, fill it with high-purity nitrogen to a pressure of 7.5MPa, turn on the electricity and ignite it, and carry out the self-propagating high-temperature synthe...

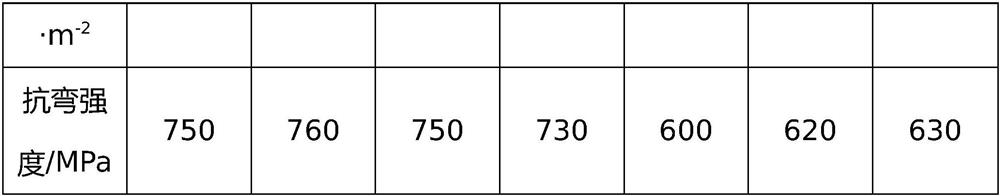

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com