A heat-resistant titanium alloy

A titanium alloy, heat-resistant technology, applied in the field of heat-resistant titanium alloys, can solve the problems of unsatisfactory thermal strength of the alloy, high manufacturing cost, poor processing performance, etc., so as to improve the high temperature creep resistance and improve the surface oxidation resistance. , the effect of good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

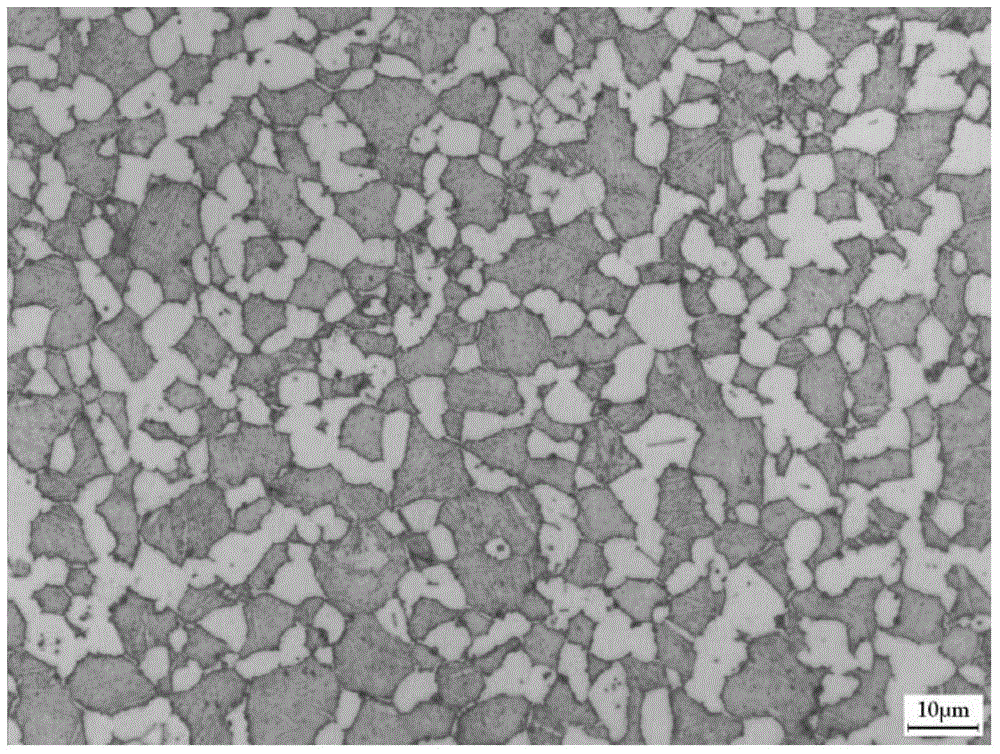

Embodiment 1

[0025] The heat-resistant titanium alloy of this embodiment is composed of the following components in weight percentage: Al 10.0%, Nb 5.0%, Zr 3.0%, Mo 2.0%, Sn 1.5%, Ta 0.5%, Si 0.2%, C 0.04% , the balance being Ti and unavoidable impurities.

[0026] The preparation method of the heat-resistant titanium alloy in this example is as follows: Al-Mo master alloy, Al-Nb master alloy, Al-Sn master alloy, zirconium sponge, pure tantalum powder (mass purity not less than 99.7%), aluminum bean and 0-grade sponge titanium, the above raw materials are mixed evenly and then pressed to obtain electrodes. The electrodes are melted by vacuum consumable arc melting to obtain alloy ingots. Carry out billet forging and high-temperature forging twice, then roll on a hot rolling mill, and then undergo solution treatment and aging treatment to obtain a heat-resistant titanium alloy rod with a circular cross-section. The heat-resistant titanium alloy rod The cross-sectional diameter of the mate...

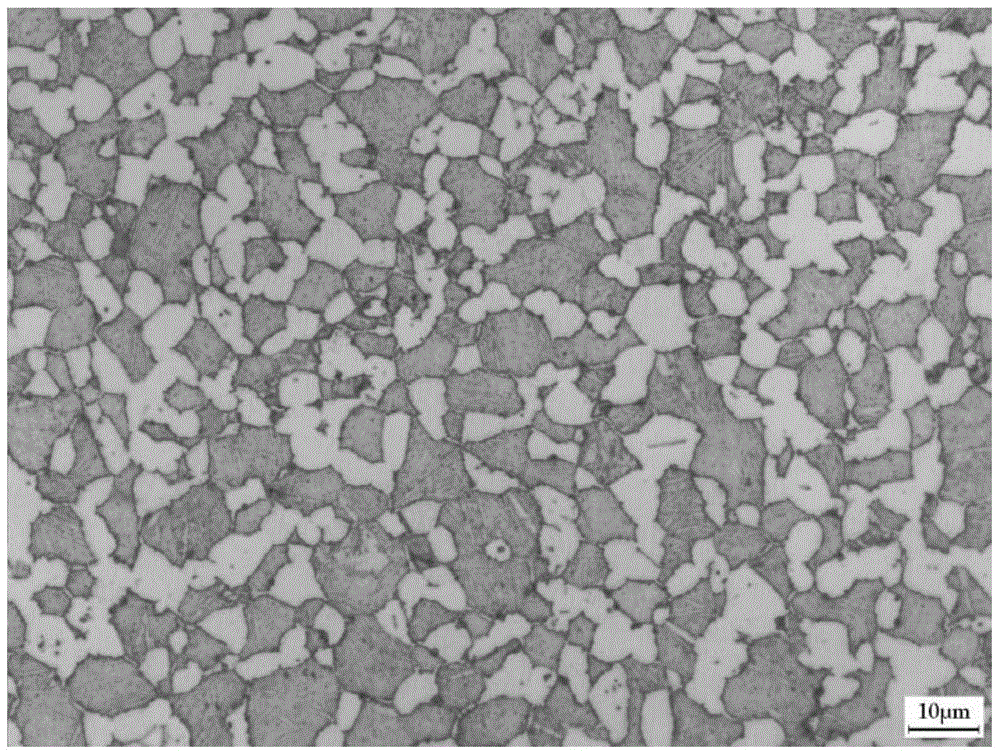

Embodiment 2

[0029] The heat-resistant titanium alloy of this embodiment is composed of the following components in weight percentage: Al 11.0%, Nb 5.5%, Zr 3.5%, Mo 2.0%, Sn 2.0%, Ta 0.75%, Si 0.3%, C 0.06% , the balance being Ti and unavoidable impurities.

[0030] The preparation method of the heat-resistant titanium alloy in this example is as follows: Al-Mo master alloy, Al-Nb master alloy, Al-Sn master alloy, zirconium sponge, pure tantalum powder (mass purity not less than 99.7%), aluminum bean and 0-grade sponge titanium, the above raw materials are mixed evenly and then pressed to obtain electrodes. The electrodes are melted by vacuum consumable arc melting to obtain alloy ingots. Carry out billet forging and high-temperature forging twice, then roll on a hot rolling mill, and then undergo solution treatment and aging treatment to obtain a heat-resistant titanium alloy rod with a circular cross-section. The heat-resistant titanium alloy rod The cross-sectional diameter of the mat...

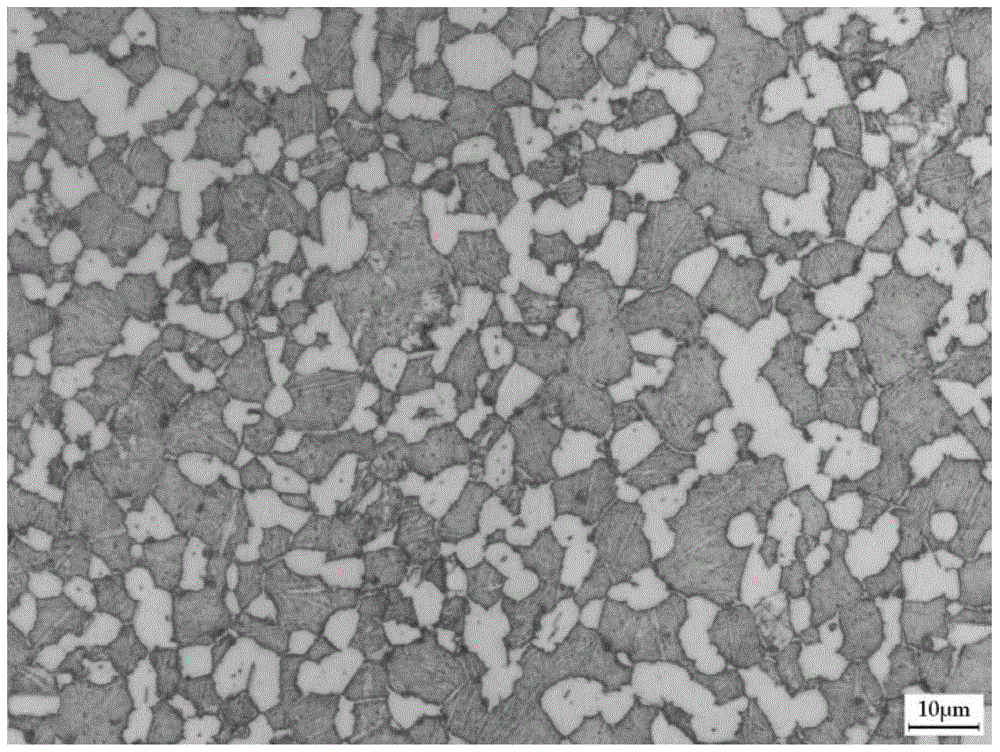

Embodiment 3

[0033] The heat-resistant titanium alloy of this embodiment is composed of the following components in weight percentage: Al 12.0%, Nb 6.0%, Zr 4.0%, Mo 2.0%, Sn 2.5%, Ta 1.0%, Si 0.4%, C 0.08% , the balance being Ti and unavoidable impurities.

[0034] The preparation method of the heat-resistant titanium alloy in this example is as follows: Al-Mo master alloy, Al-Nb master alloy, Al-Sn master alloy, zirconium sponge, pure tantalum powder (mass purity not less than 99.7%), aluminum bean and 0-grade sponge titanium, the above raw materials are mixed uniformly and then pressed to obtain electrodes. The electrodes are melted by vacuum consumable arc melting to obtain alloy ingots. Carry out billet forging and high-temperature forging twice, then roll on a hot rolling mill, and then undergo solution treatment and aging treatment to obtain a heat-resistant titanium alloy rod with a circular cross-section. The heat-resistant titanium alloy rod The cross-sectional diameter of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com