Core-shell type nanostructured polymeric microsphere fire retardant, preparation method and application of core-shell type nanostructured polymeric microsphere fire retardant

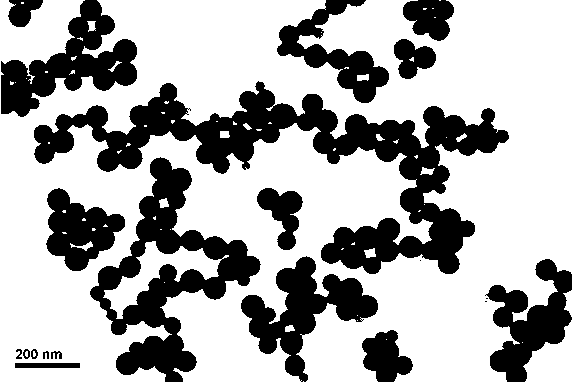

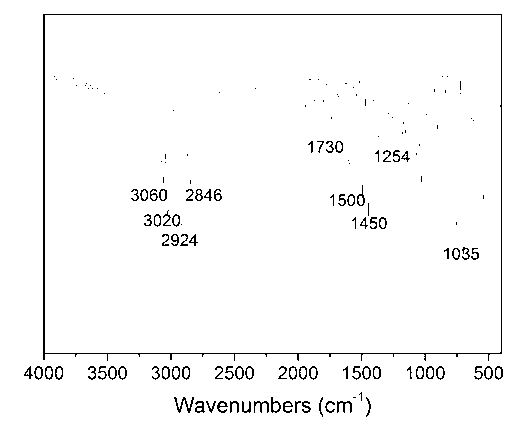

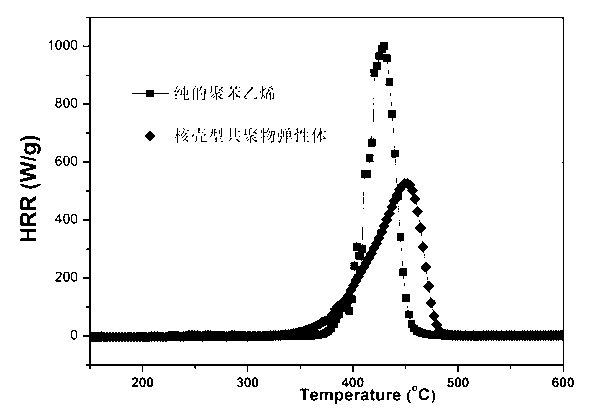

A nano-polymer, core-shell technology, which is applied in the field of core-shell nano-polymer microsphere flame retardants and their preparation, can solve the problem of no nano-polymer microsphere flame retardants and no halogen-free flame retardants. , product performance deterioration and other issues, to achieve the effect of reducing migration, lasting flame retardant performance, improving dispersion and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, monomer I is firstly prepared. The method can refer to the content disclosed in the patent of Chinese Patent Publication No. 102391403A. The specific operation process is as follows: in a 250ml three-necked bottle equipped with mechanical stirring and constant pressure dropping funnel, add 12.2 g (0.2mol) ethanolamine and 40ml tetrahydrofuran, stir at room temperature, after 10 minutes, add 40.0g (0.4mol) formaldehyde solution (concentration: 30%), stir and raise the temperature to 70 ° C, under continuous stirring within 2 hours 44.0 g (0.40 mol) of dimethyl phosphite was added dropwise, and the reaction was stopped after 10 hours of reaction. The tetrahydrofuran solvent was removed, the crude product was dissolved in 100 ml of chloroform, washed three times with 10 ml of 0.1 mol / L sodium hydroxide solution, dried and the chloroform was removed to obtain a light yellow transparent liquid. Then take 45.7g (0.15mol) of the light yellow transparent liq...

Embodiment 2

[0037] (1) Fully stir and mix 40 parts of monomer I, 20 parts of styrene, 50% of the total mass of emulsifier and 50% of the total mass of deionized water to prepare a pre-emulsion of the core layer monomer;

[0038] (2) Fully stir and mix 20 parts of monomer I, 20 parts of styrene, the rest of the emulsifier and deionized water to prepare the shell monomer pre-emulsion;

[0039] (3), add 50% of the total mass of the pH regulator and 50% of the total mass of the initiator to the nuclear layer monomer pre-emulsion obtained in step (1), then stir and mix and heat up to 70°C, and keep it warm for 60 minutes to prepare Obtain core polymer emulsion;

[0040] (4) Heat the core polymer emulsion prepared in step (3) to 75°C, add the remaining pH regulator, and then drop the previously obtained shell monomer pre-emulsion and the remaining initiator solution simultaneously and at a constant speed Add it, keep it warm for 60 minutes after the dropwise addition, and then drop to room tem...

Embodiment 3

[0044] (1) Fully stir and mix 40 parts of monomer I, 20 parts of ethyl acrylate, 50% of the total mass of emulsifier and 70% of the total mass of deionized water to prepare a pre-emulsion of the core layer monomer;

[0045] (2) Fully stir and mix 20 parts of monomer I, 20 parts of ethyl acrylate, the remaining emulsifier and deionized water to prepare a shell monomer pre-emulsion;

[0046] (3), add 50% of the total mass of the pH regulator and 60% of the total mass of the initiator to the nuclear layer monomer pre-emulsion obtained in step (1), then stir and mix and heat up to 65°C, and keep it warm for 60 minutes to prepare Obtain core polymer emulsion;

[0047] (4) Heat the core polymer emulsion prepared in step (3) to 70°C, add the remaining pH regulator, and then drop the previously obtained shell monomer pre-emulsion and the remaining initiator solution simultaneously and at a constant speed Add it, keep warm for 40 minutes after the dropwise addition, and then drop to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com