PLA/PPC/HBP (poly lactic acid/propylene oxide copolymer/hyperbranched polymer derivative blend and preparation method thereof

A technology of derivatives and blends, applied in the field of PLA/PPC/HBP derivative blends and their preparation, can solve the problems of large difference in polarity and insignificant modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

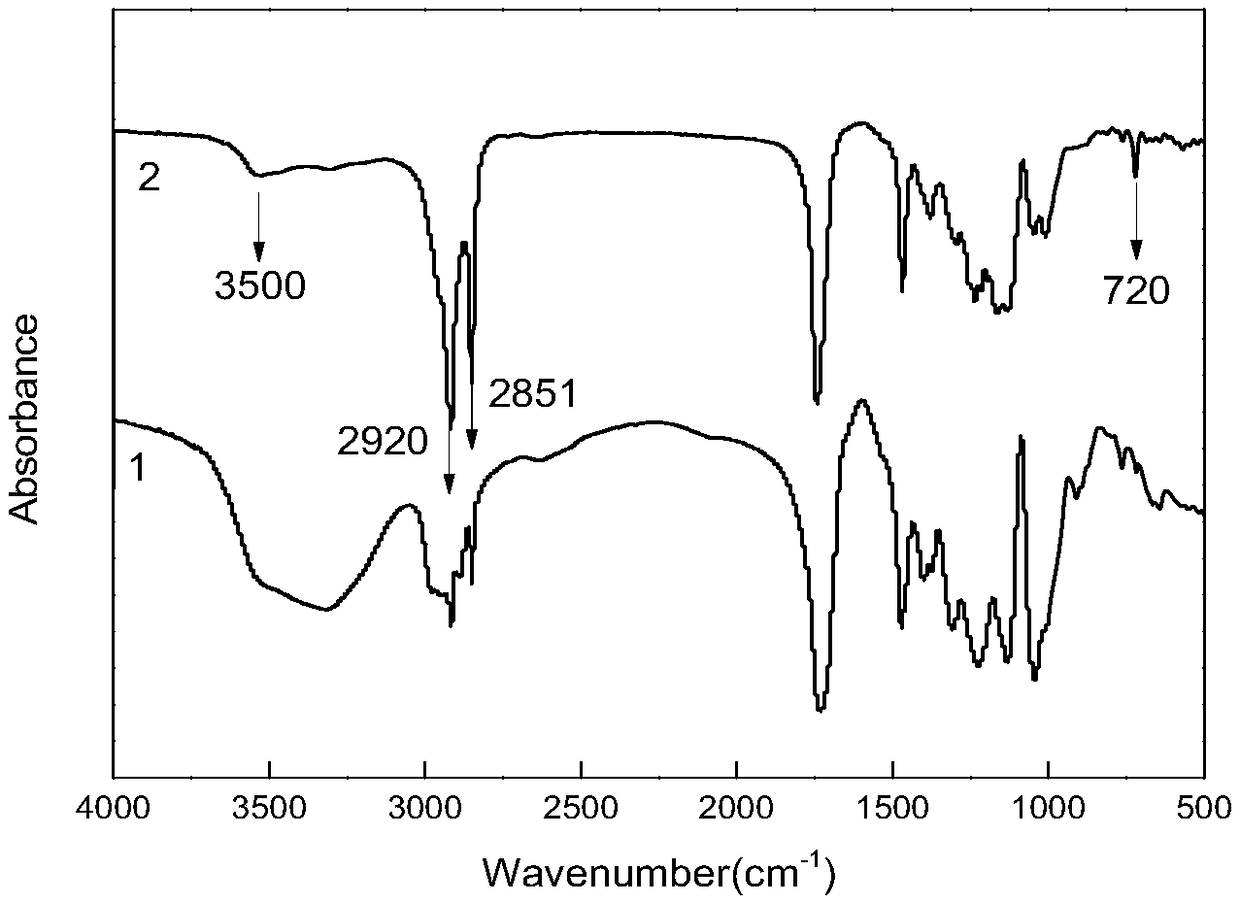

[0039] The synthesis of embodiment 1 long chain branch type hyperbranched polyester (HBP derivative)

[0040] Step 1. Synthesis of HBPE

[0041] The HBPE with TMP as the core is synthesized by melt polycondensation "one-step method". The synthetic reaction schematic diagram is shown below. The specific reaction steps are: add 42.21gDMPA, 2.01gTMP, and 25mgP-TSA to the three-necked flask, and put the reflux condenser, thermometer Connect the stirrer to the three-necked flask respectively, and then put it into the oil bath, first heat the oil bath to 120°C, preheat for 10 minutes and then raise the temperature to 140°C, start timing when the reactants are completely melted, nitrogen protection Lower reaction 2.5h; Then use circulating water pump decompression (100Pa) after reaction 2.0h, stop reaction, the reaction product is poured out from the flask quickly, after it cools down, become hard and brittle translucent solid, the product Place in the oven to dry and set aside.

...

Embodiment 2

[0050] The synthesis of embodiment 2 long chain branch type hyperbranched polyester (HBP derivative)

[0051] Step 1. Synthesis of HBPE

[0052] The HBPE with TMP as the core is synthesized by the "one-step method" of melt polycondensation. The synthetic reaction schematic diagram is shown below. g trimethylolpropane (TMP) and 25mg p-toluenesulfonic acid (P-TSA); the agitator, reflux condenser, and thermometer are respectively connected to a three-necked flask, then it is put into an oil bath, and firstly preheated to 120°C, warm up to 135°C after preheating for 10 minutes, start timing when the reactants in the flask are completely melted, and react at normal pressure for 3 hours under the protection of nitrogen; Pour it out from the flask, and after cooling, a translucent solid is obtained which is the target product.

[0053]

[0054]

[0055] R2 is:

[0056] Step 2. Synthesis of HBP derivatives

[0057] Add 20g of HBPE to the three-necked flask, put it into an ...

Embodiment 3

[0061] The synthesis of embodiment 3 long-chain branched type hyperbranched polyester (HBP derivative)

[0062] Step 1. Synthesis of HBPE

[0063] The HBPE with TMP as the core is synthesized by melt polycondensation "one-step method". The synthetic reaction schematic diagram is shown below. g trimethylolpropane (TMP) and 25mg p-toluenesulfonic acid (P-TSA); the agitator, reflux condenser, and thermometer are respectively connected to a three-necked flask, then it is put into an oil bath, and firstly preheated to 120°C, warm up to 145°C after preheating for 10 minutes, start timing when the reactants in the flask are completely melted, and react for 2 hours under normal pressure under the protection of nitrogen; then react for 3 hours under reduced pressure (95Pa) with a water pump, stop the reaction, and transfer the molten product from the flask Poured out, after cooling, a translucent solid was obtained which was the target product.

[0064]

[0065] R2 is:

[0066]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com