Epoxy resin curing agent, and preparation method and application of epoxy resin curing agent

A technology of epoxy resin curing and compounding, applied in adhesive additives, non-polymer adhesive additives, coatings, etc., can solve the problems of poor compatibility of tougheners, affecting the safety and life of epoxy materials , to achieve the effects of low cost, good toughening effect and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of epoxy resin curing agent comprises the following steps:

[0022] (1) Measure and weigh polyamine and mercapto acid compounds according to a certain molar ratio, add polyamine into a flask equipped with stirring first, then add excess silica gel desiccant into reaction flask, heat up to 100°C, drop Add the mercapto acid compound, drop it within 30 minutes, raise the temperature to 160-200°C for 3-6 hours after the drop, remove the silica gel desiccant by filtration, and get the amidated mercapto-modified compound;

[0023] (2) After mixing the amidated mercapto-modified compound and amino polyether in a reaction kettle, stir at room temperature for 20-40 minutes to obtain the product.

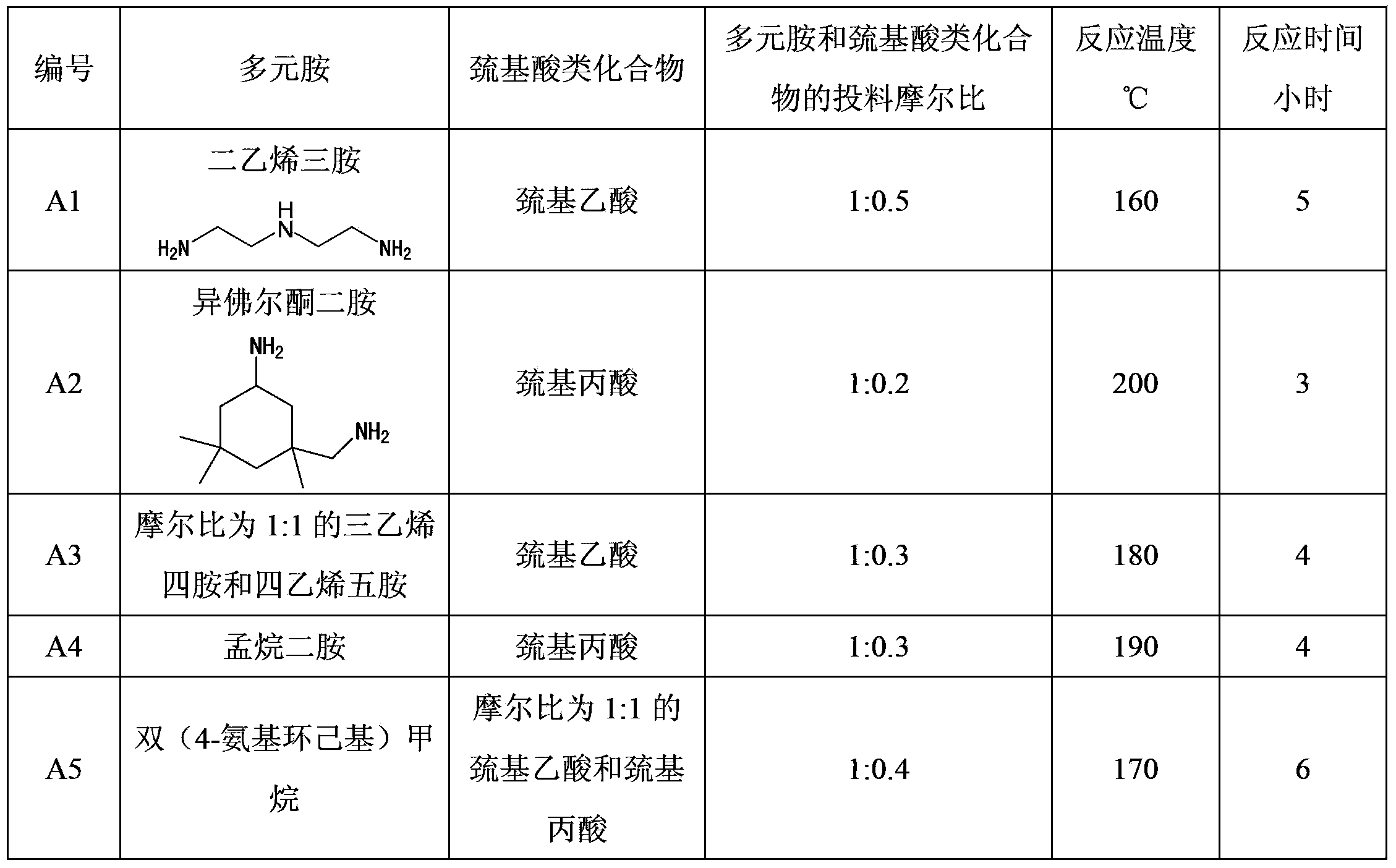

[0024] Wherein, in step (1), the reaction conditions are shown in Table 1.

[0025] Table 1 Reaction conditions of step (1)

[0026]

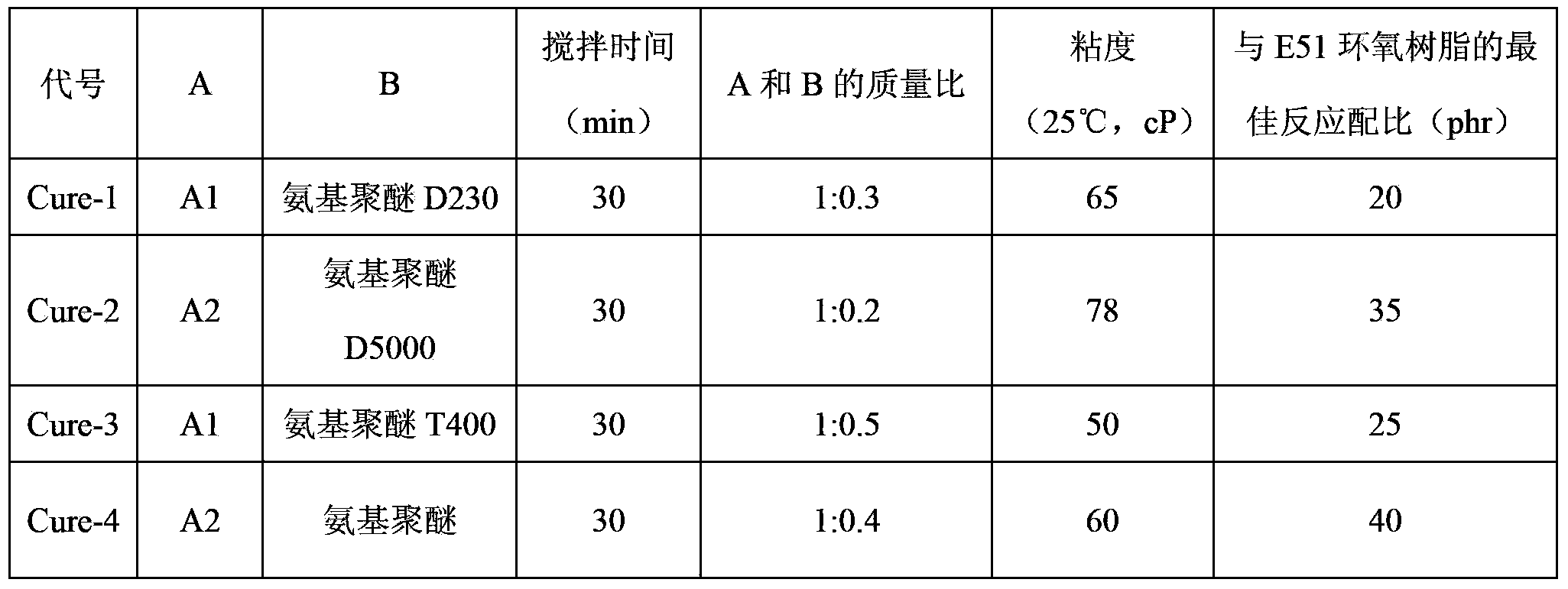

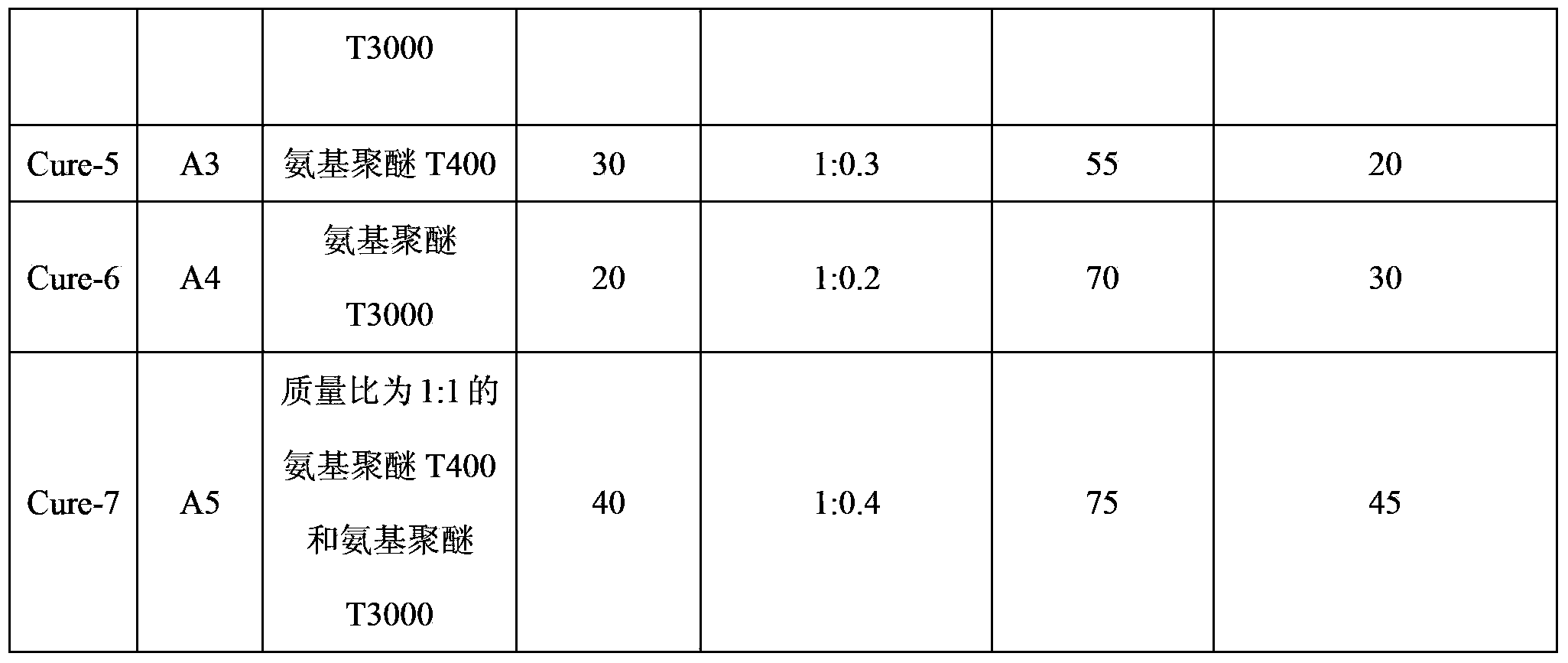

[0027] Wherein, in step (2), the reaction conditions are shown in Table 2.

[0028] Table 2 Reaction conditions of step (2)

[0...

Embodiment 2

[0032] Preparation of cured epoxy resin:

[0033] Using the seven curing agents prepared in Example 1, the commercially available phenolic modified T31 curing agent (specially used for low-temperature curing in Changsha Chemical Industry), diethylenetriamine (DETA) and isophoronediamine (IPDA) were mixed with E51 epoxy The resin is mixed according to the optimal reaction ratio to prepare the cured epoxy resin.

[0034] The surface dry time, tensile strength, elongation, tensile elastic modulus and steel-steel tensile shear strength under low temperature conditions were tested respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com