Low-creep high-toughness cycloolefin copolymer composite material and preparation method thereof

A technology of cycloolefin copolymers and composite materials, which is applied in the field of engineering plastics, can solve the problems of poor toughness of recycled materials, and achieve the effects of prolonging the service life, expanding the scope of use, and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

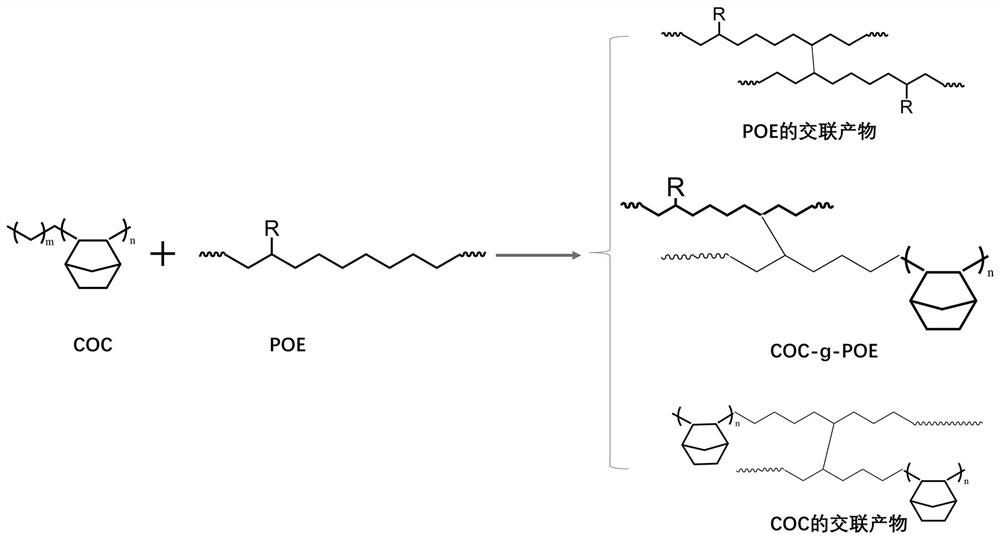

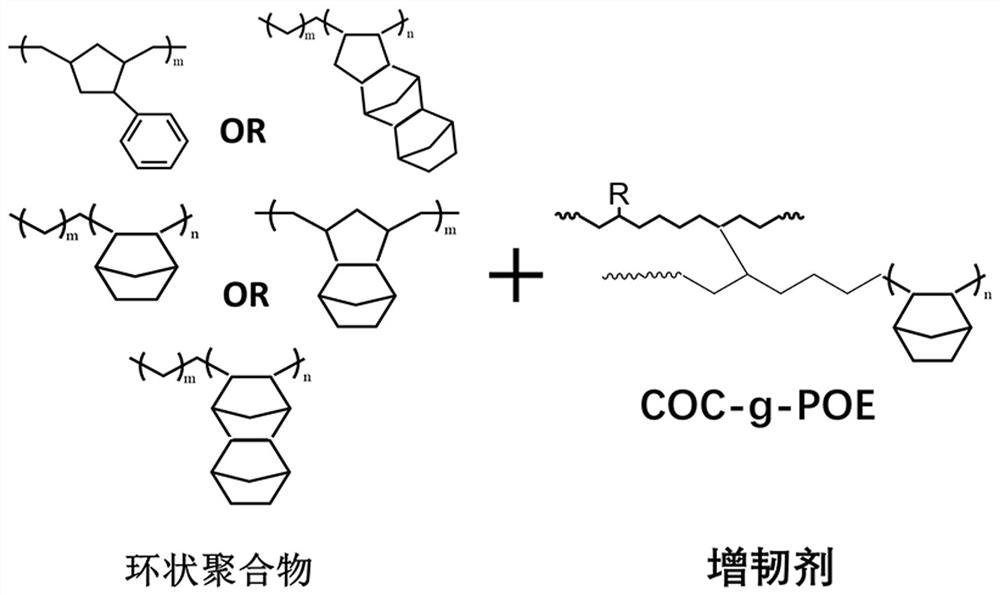

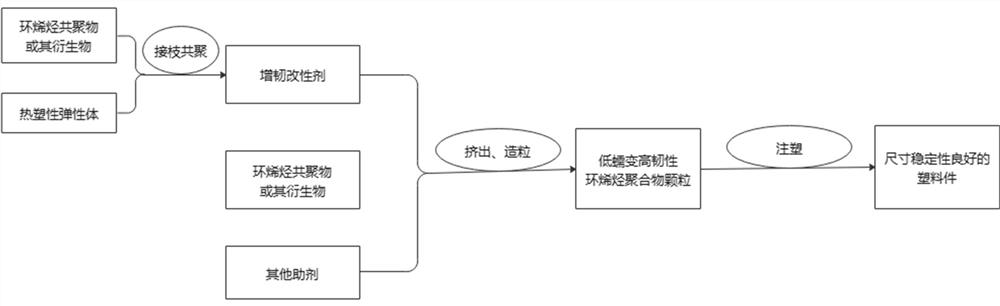

[0029] The preparation steps of the toughening modifier: (1) Weigh 100 parts by weight of cycloolefin copolymer resin COC or COP, 50 parts by weight to 160 parts by weight of the toughening agent, the toughening agent is selected from POE, SEBS, One or more compositions of SEPS and OBC; (2) Melt and mix the above raw materials in a twin-screw extruder; (3) Put the blended material into an internal mixer, and add 1 to 5 parts by weight part of free radical initiator, and react for 5 to 25 minutes at a melting temperature of 180°C to 240°C; (4) After the mixed material is unloaded from the internal mixer, a single-screw extruder is used to prepare uniform granular materials.

[0030]Melt grafting is a reaction in which the primary free radicals generated by the initiator capture the hydrogen atoms on the hydrocarbon chain and generate macromolecular free radicals to initiate monomer polymerization. The reaction temperature is generally above the melting point or softening point ...

Embodiment 1

[0036] Example 1 (1) Preparation of POE toughening modifier: 5kg of POE, add 4kg cycloolefin copolymer (COC), fully mix in high-speed mixer, add twin-screw extruder, at 180 ℃ ~ 240 Under the condition of ℃, fully melt and mix. Then, put the resin into the internal mixer, add 100g of peroxide initiator (BIPP), and react for 25min in the molten state at 200°C. After the reaction is completed, a single-screw extruder is used to prepare uniform granular materials. COC can also be adjusted to COP, and POE toughening modifiers can be prepared according to the above component ratios and steps.

[0037] (2) Testing the grafting rate of POE: the product was fully extracted with toluene, and the yield of coagulation was less than 1%. Use cyclohexane to realize the separation of POE and COC materials, and measure the grafting rate of POE by gravimetric method, and the grafting rate of COC molecular chains on POE molecular chains is >4.7%. The grafting rate generally refers to the weigh...

Embodiment 2

[0038] Embodiment 2 (1) Preparation of SEBS toughening modifier: 5kg of SEBS, add 4kg cycloolefin copolymer (COC), after fully mixing in high-speed mixer, add twin-screw extruder, at 180 ℃~240 Under the condition of ℃, fully melt and mix. Then, put the resin into the internal mixer, add 120g of peroxide initiator (BIPP), and react for 25min in molten state at 200°C. After the reaction is completed, use a single-screw extruder to prepare uniform granular materials. COC can also be adjusted to COP, and SEBS toughening modifiers can be prepared according to the above-mentioned component ratios and steps.

[0039] (2) Test the grafting rate of SEBS: use toluene to fully extract the product, and the yield of coagulation is less than 0.8%. SEBS and COC materials were separated by cyclohexane, and the grafting rate of SEBS was tested by gravimetric method. The grafting rate of COC molecular chains on SEBS molecular chains was >6.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com