Sprayed concrete containing high polymer modified fibers

A technology of shotcrete and high polymer modification, which is applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc. It can solve the problem of unsatisfactory mechanical properties of shotcrete, inability to fully exert the toughening effect, Uneven distribution of polypropylene crude fibers, etc., to achieve cohesive change, good cohesiveness, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

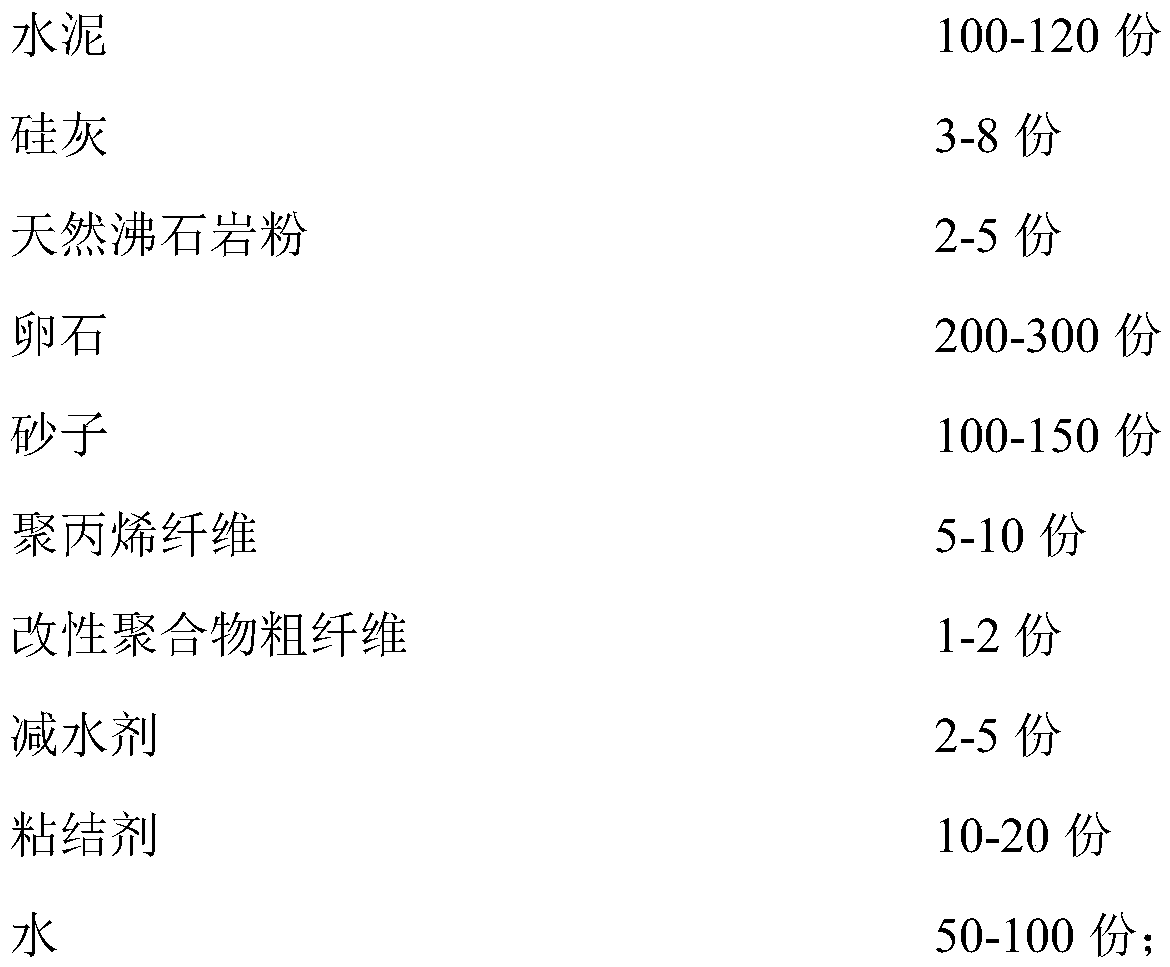

[0038] A shotcrete containing high polymer modified fibers, including the following raw materials in parts by mass:

[0039]

[0040] in,

[0041] The modified polymer crude fiber is prepared from polypropylene-polyethylene glycol block polymer, and the polyethylene glycol chain segment is terminated by monomethyl ether.

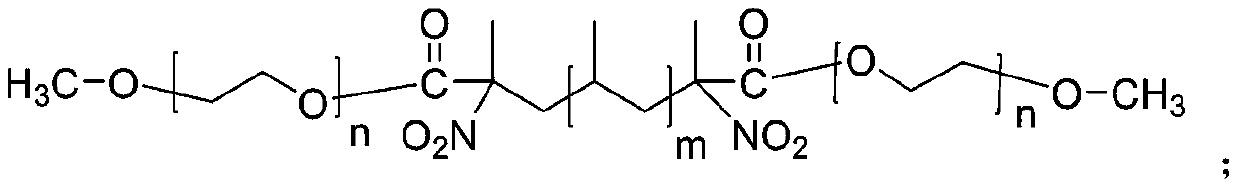

[0042] The block polymer of described polypropylene-polyethylene glycol has following chemical structure:

[0043]

[0044] in,

[0045] m is about 3000;

[0046] n is 5.

[0047] The cement is Portland cement with a strength of 42.5.

[0048] The polyacrylic acid water reducer is purchased from Sumitomo, Japan, and the brand is Carbomer HV-501.

[0049] The preparation method of the modified polymer crude fiber is as follows:

[0050] S1. Blend polypropylene with a degree of polymerization of about 3000 with concentrated nitric acid of twice the mass, react at 80°C for 1 hour, then pour into water, filter, and dry in an oven to obtain carboxyl-t...

Embodiment 2

[0056] A shotcrete containing high polymer modified fibers, including the following raw materials in parts by mass:

[0057]

[0058] in,

[0059] The modified polymer crude fiber is prepared from polypropylene-polyethylene glycol block polymer, and the polyethylene glycol chain segment is terminated by monomethyl ether.

[0060] The block polymer of described polypropylene-polyethylene glycol has following chemical structure:

[0061]

[0062] in,

[0063] M is about 8000;

[0064] n is 10.

[0065] The cement is Portland cement with a strength of 42.5R.

[0066] The polyether-type polycarboxylate water reducer is purchased from Kaidi Building Materials, and the brand name is KD-501.

[0067] The preparation method of the modified polymer crude fiber is as follows:

[0068] S1. Blend polypropylene with a degree of polymerization of about 8000 with 3 times the mass of concentrated nitric acid, react at 100°C for 3 hours, then pour it into water, filter, and dry in ...

Embodiment 3

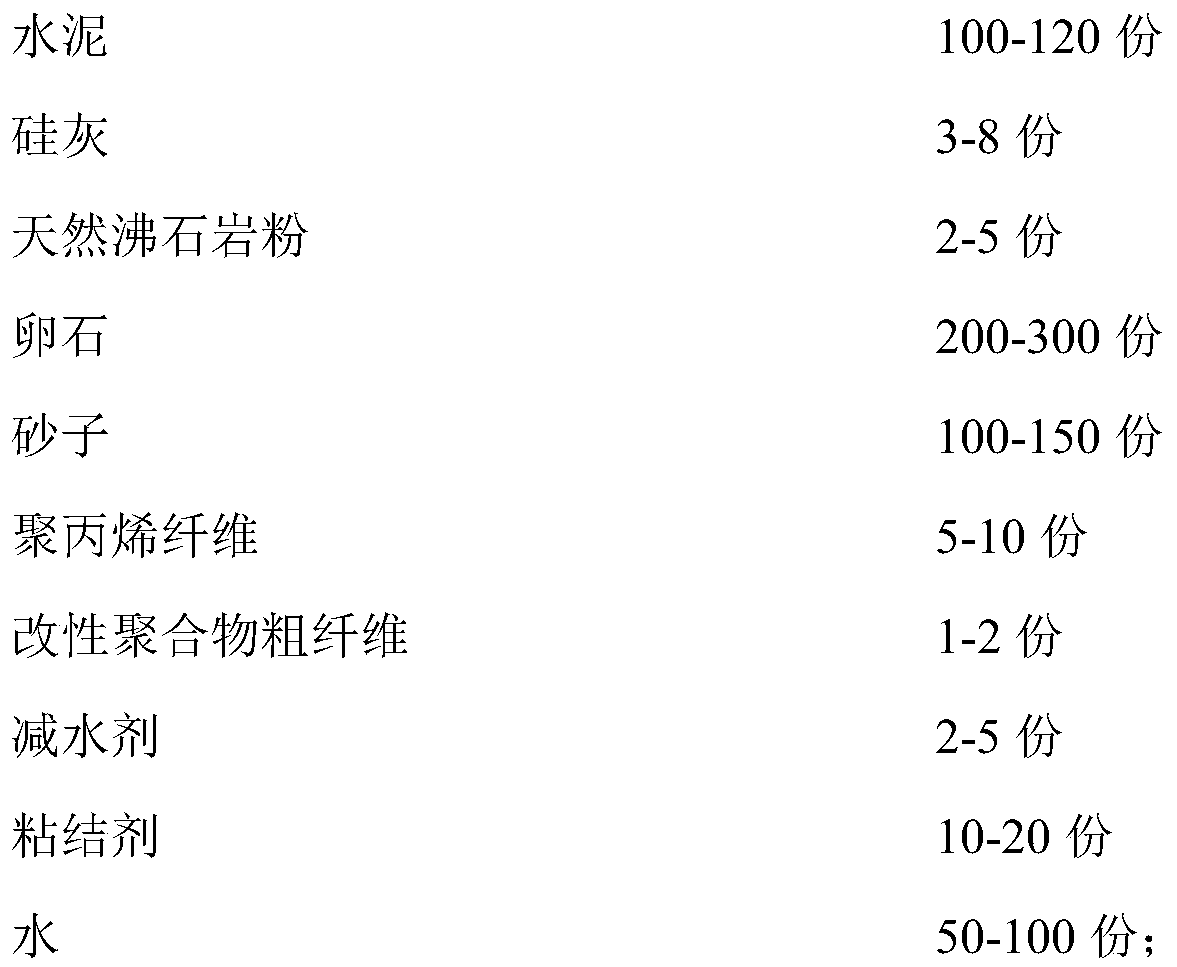

[0074] A shotcrete containing high polymer modified fibers, including the following raw materials in parts by mass:

[0075]

[0076]

[0077] in,

[0078] The modified polymer crude fiber is prepared from polypropylene-polyethylene glycol block polymer, and the polyethylene glycol chain segment is terminated by monomethyl ether.

[0079] The block polymer of described polypropylene-polyethylene glycol has following chemical structure:

[0080]

[0081] in,

[0082] M is about 6000;

[0083] n is 8.

[0084] The cement is Portland cement with a strength of 52.5R.

[0085] The polyacrylic acid water reducer is purchased from Sumitomo, Japan, and the brand is Carbomer HV-501.

[0086] The preparation method of the modified polymer crude fiber is as follows:

[0087] S1. Blend polypropylene with a degree of polymerization of about 6000 with concentrated nitric acid of twice the mass, react at 90°C for 2 hours, then pour it into water, filter, and dry in an oven to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com