Road with long service life and construction method thereof

A long-life, road-friendly technology, applied to roads, roads, on-site paved condensate pavements, etc., can solve the problems of roads without fire resistance, short service life, and easily damaged roads, and achieve excellent waterproof and long service life , The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

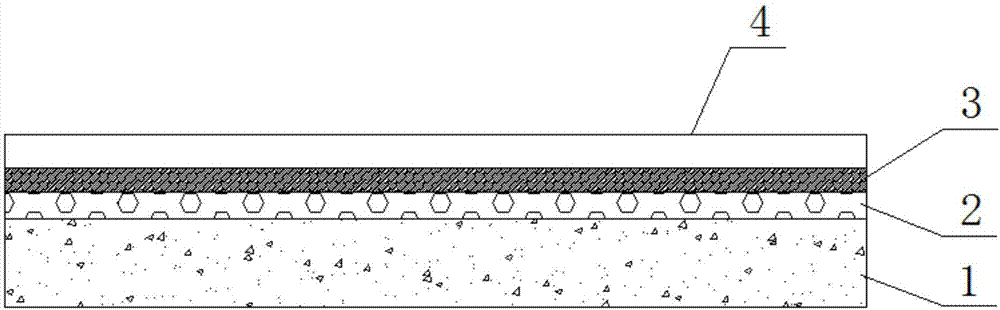

[0039] The invention discloses a road with a long service life, which includes a base layer 1, a waterproof layer 2 is arranged on the upper surface of the base layer 1, and a fireproof layer is arranged on the upper surface of the waterproof layer 2. Layer 3, a layer of toughening layer 4 is arranged on the upper surface of the fireproof layer 3 .

[0040] Preferably, the base layer 1 is prepared from the following components in parts by weight: 35 parts of cement, 20 parts of stone sand, 15 parts of fly ash, and 40 parts of water.

[0041] Preferably, the waterproof layer 2 is prepared from the following components in parts by weight: 35 parts of cement, 10 parts of waterproofing agent, and 30 parts of water.

[0042] Preferably, the fireproof layer 3 is prepared from the following components in parts by weight: 40 parts of cement, 20 parts of yellow sand, 10 parts of quartz sand, 7 parts of fireproofing agent, and 40 parts of water.

[0043] Preferably, the toughening laye...

Embodiment 2

[0054] The invention discloses a road with a long service life, which includes a base layer 1, a waterproof layer 2 is arranged on the upper surface of the base layer 1, and a fireproof layer is arranged on the upper surface of the waterproof layer 2. Layer 3, a layer of toughening layer 4 is arranged on the upper surface of the fireproof layer 3 .

[0055] Preferably, the base layer 1 is prepared from the following components in parts by weight: 30 parts of cement, 15 parts of stone sand, 20 parts of fly ash, and 35 parts of water.

[0056] Preferably, according to parts by weight, the waterproof layer 2 is prepared from the following components: 45 parts of cement, 8 parts of waterproofing agent, and 40 parts of water.

[0057] Preferably, the fireproof layer 3 is prepared from the following components in parts by weight: 30 parts of cement, 10 parts of yellow sand, 15 parts of quartz sand, 5 parts of fireproofing agent, and 50 parts of water.

[0058] Preferably, the toughen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com