Preparation method for tough epoxy acid anhydride impregnating varnish and impregnating varnish

An epoxy acid anhydride and impregnating paint technology, applied in the field of impregnating paint, can solve the problems of incompatibility between inorganic nanoparticles and epoxy resin, defects in impregnating paint, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

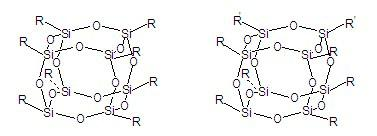

Image

Examples

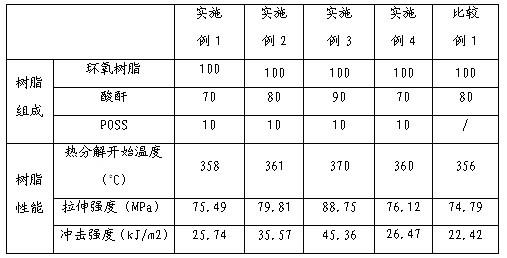

Embodiment 1

[0024] Put 100.0g of bisphenol A epoxy resin into the reaction kettle, raise the temperature to 60°C, add 90.0g of methyltetrahydrophthalic anhydride, stir for 30min, then add 10.0g of POSS containing aliphatic epoxy groups, at a speed of 100 Continue stirring at -200rpm for 1h to form a uniform and transparent solution.

Embodiment 2

[0026] Put 100.0g of bisphenol F epoxy resin into the reaction kettle, raise the temperature to 60°C, add 70.0g of methyl nadic acid anhydride, stir for 30 min, then add 10.0g of POSS containing aliphatic epoxy group, continue at the speed of 100-200rpm Stir for 1 h to form a uniform and transparent solution.

Embodiment 3

[0028] Put 100.0g of novolac epoxy resin into the reaction kettle, raise the temperature to 60°C, add 80.0g of methyl nadic anhydride, stir for 30 min, then add 10.0g of POSS containing aliphatic epoxy groups, and continue stirring at a speed of 100-200rpm 1h to form a uniform and transparent solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com