Preparation method and material of polylactic acid-natural rubber porous material by microporous injection molding

A technology of natural rubber and porous materials, applied in the direction of coating, etc., can solve the problems of poor toughness of polylactic acid, and achieve the effect of increasing compatibility, good toughness, cell size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

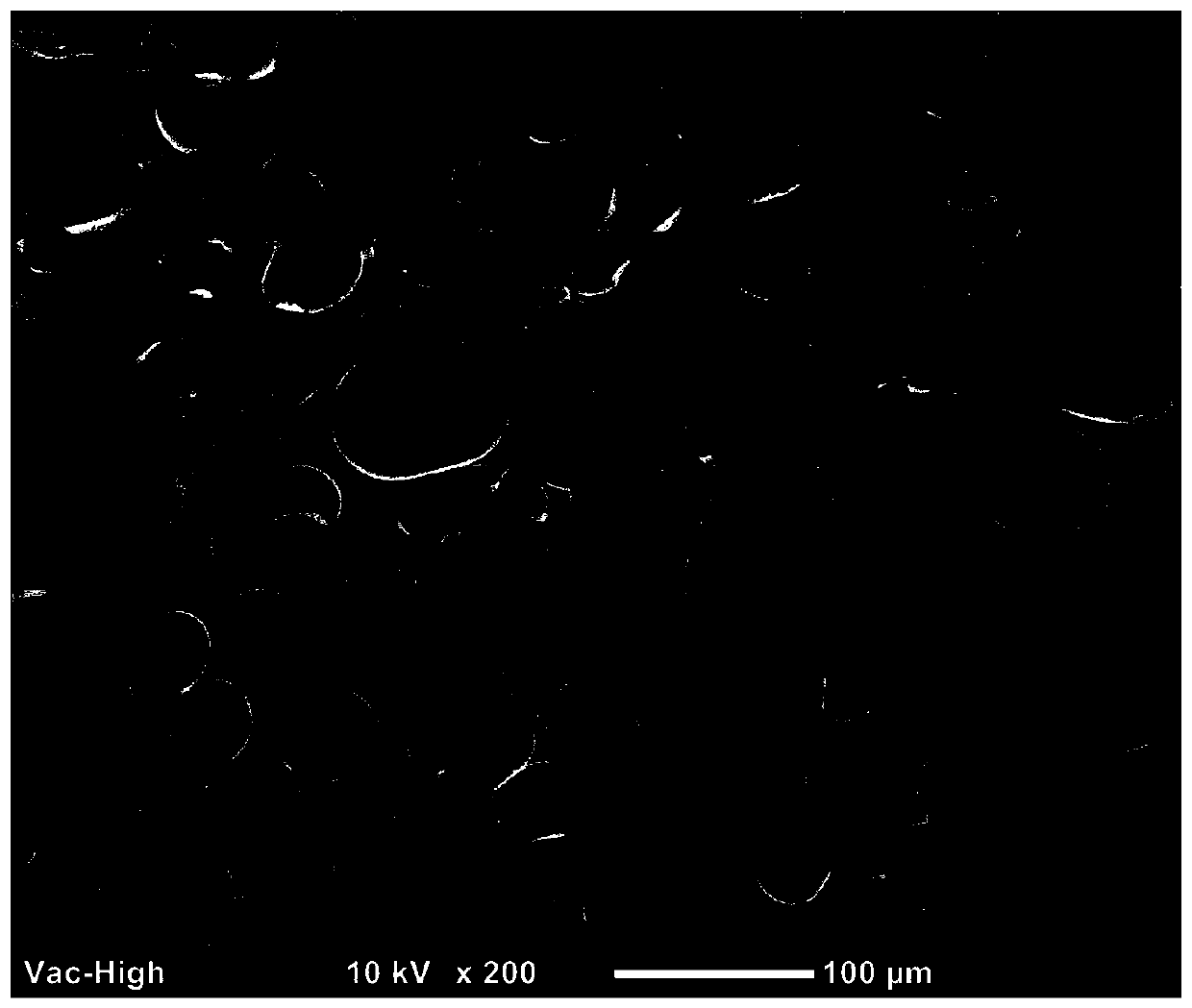

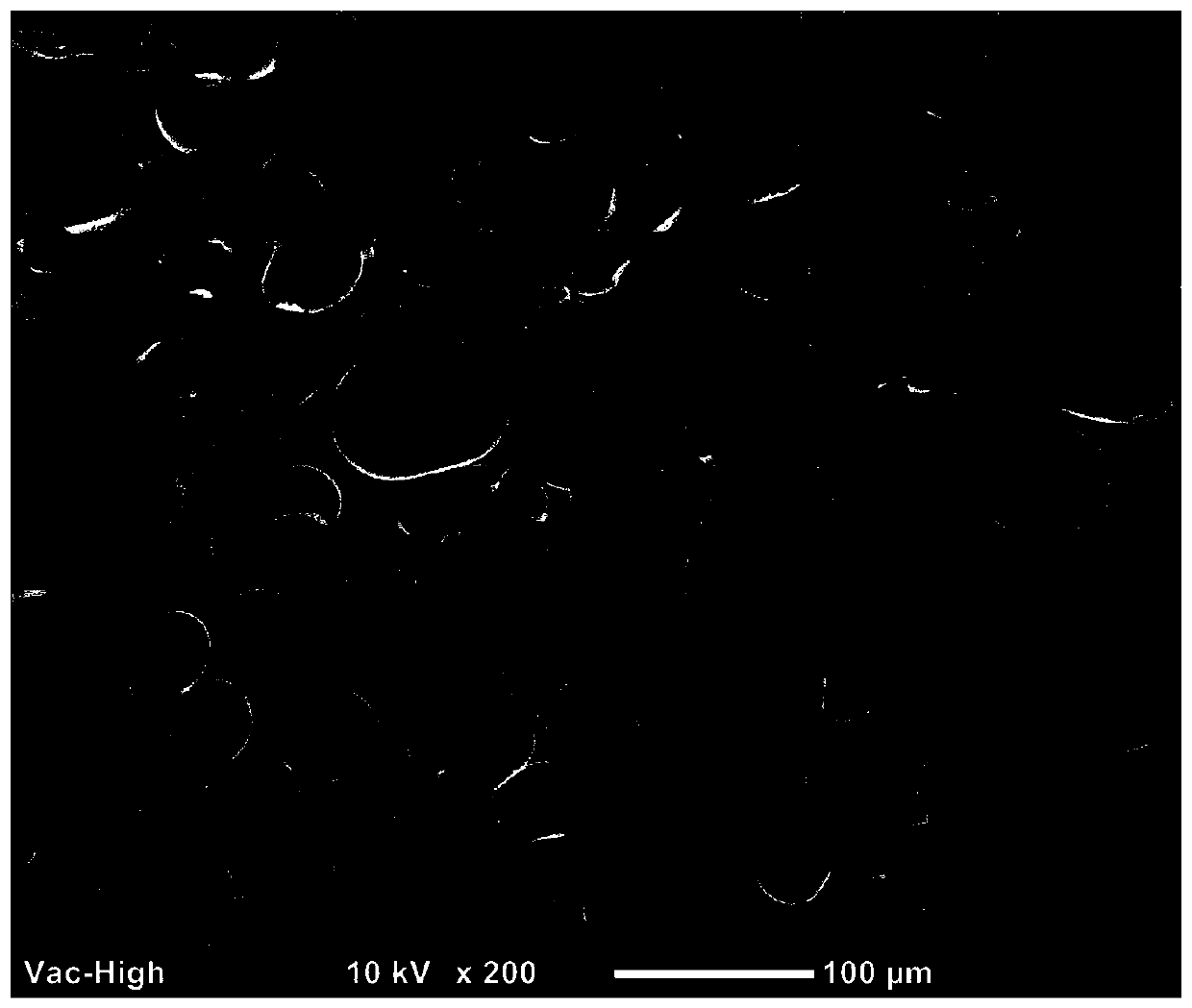

Image

Examples

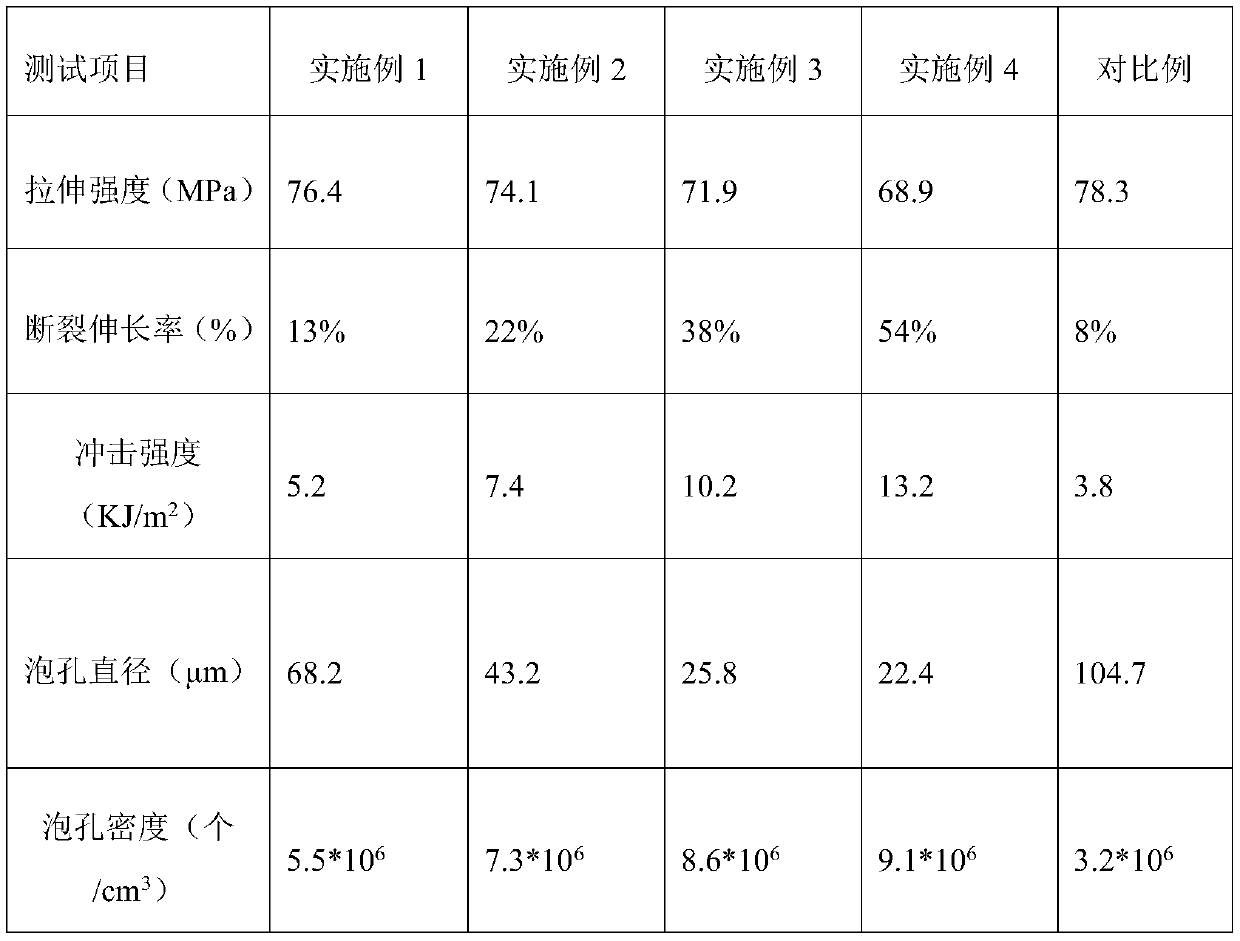

Embodiment 1

[0015] The dry polylactic acid pellets were mixed with the glycidyl methacrylate-natural rubber graft at a weight ratio of 95 / 5, and extruded and granulated by a twin-screw extruder. The extrusion temperature is 190° C., and the screw speed is 100 revolutions / min.

[0016] The blend pellets were subjected to microcellular injection foaming with supercritical CO 2 The fluid is a blowing agent. Injection temperature 200°C, mold temperature 50°C, injection speed 30cm 3 / s, supercritical CO 2 The fluid accounts for 1% of the mass of the polymer, and the polylactic acid / natural rubber porous material is obtained by injection molding.

Embodiment 2

[0018] The dry polylactic acid pellets and the glycidyl methacrylate-natural rubber graft were mixed in a weight ratio of 90 / 10, and extruded and granulated by a twin-screw extruder. The extrusion temperature is 180° C., and the screw speed is 90 revolutions / min.

[0019] The blend pellets were subjected to microcellular injection foaming with supercritical CO 2 The fluid is a blowing agent. Injection temperature 190°C, mold temperature 40°C, injection speed 30cm 3 / s, supercritical CO 2 The fluid accounts for 1% of the mass of the polymer, and the polylactic acid / natural rubber porous material is obtained by injection molding.

Embodiment 3

[0021] The dry polylactic acid pellets and the glycidyl methacrylate-natural rubber graft were mixed in a weight ratio of 85 / 15, and extruded and granulated by a twin-screw extruder. The extrusion temperature was 170° C., and the screw speed was 80 revolutions / min.

[0022] The blend pellets were subjected to microcellular injection foaming with supercritical CO 2 The fluid is a blowing agent. Injection temperature 180°C, mold temperature 20°C, injection speed 40cm 3 / s, supercritical CO 2 The fluid accounts for 0.5% of the mass of the polymer, and the polylactic acid / natural rubber porous material is obtained by injection molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com