Toughening epoxy resin curing agent and preparation method and application thereof

An epoxy resin curing and toughening technology, which is applied in the field of building materials, can solve the problems of cumbersome synthesis process, high viscosity, and affecting the durability of materials, and achieve the effect of simple preparation method, low viscosity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

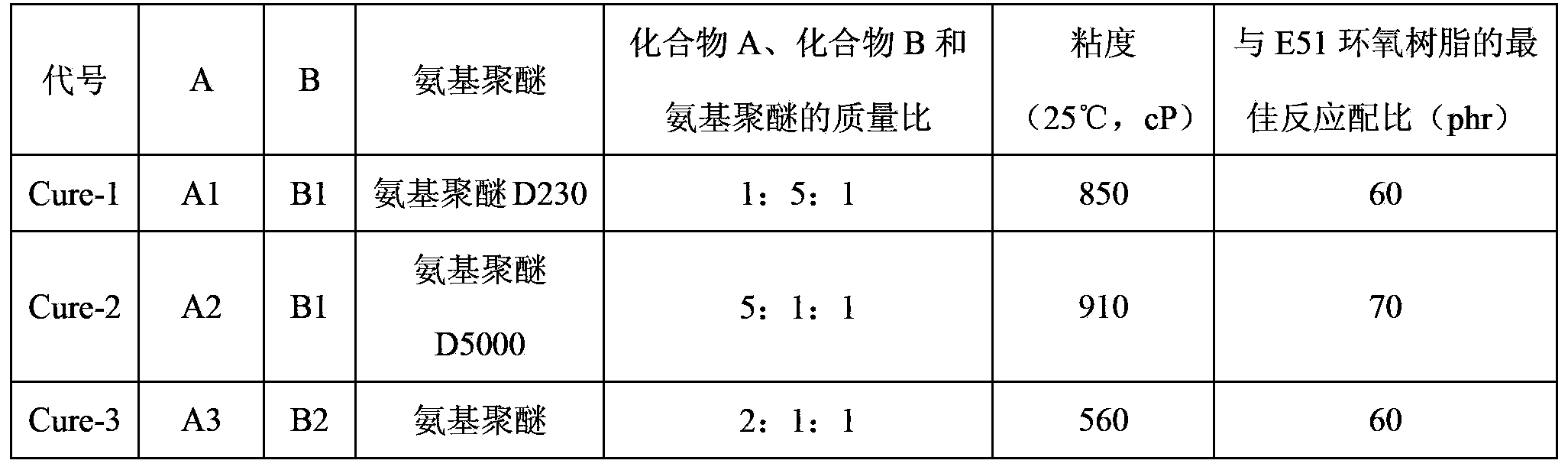

[0024] The preparation of toughening type epoxy resin curing agent comprises the following steps:

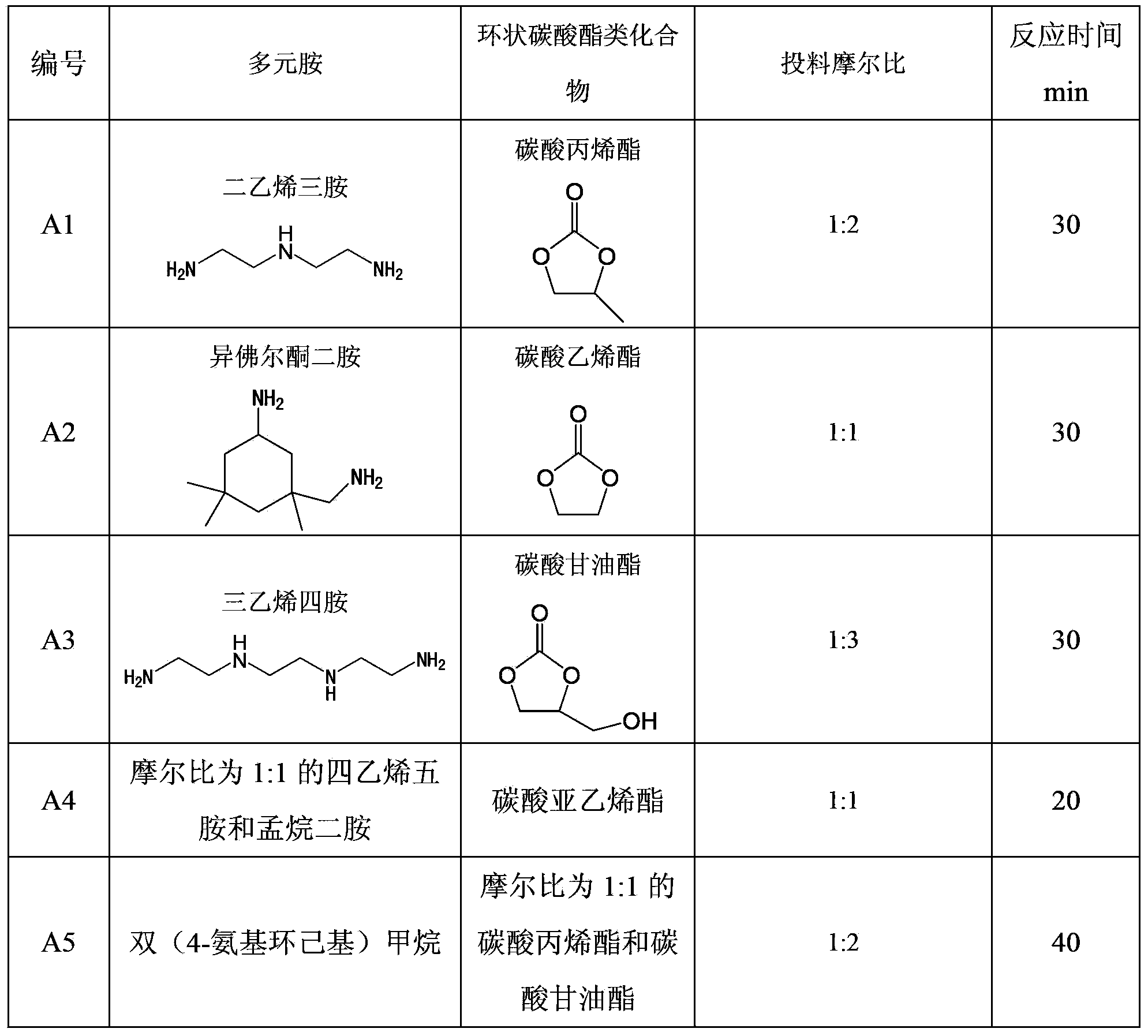

[0025] (1) Add polyamine to the flask equipped with stirring first, then add the cyclic carbonate compound dropwise at room temperature, and finish the drop within 30 minutes (cool the flask with an ice-water bath at the right time during the process to ensure that the entire The temperature of the system during the process is kept between 20 and 30°C), and compound A is obtained after stirring at room temperature for 20-40 minutes after dropping;

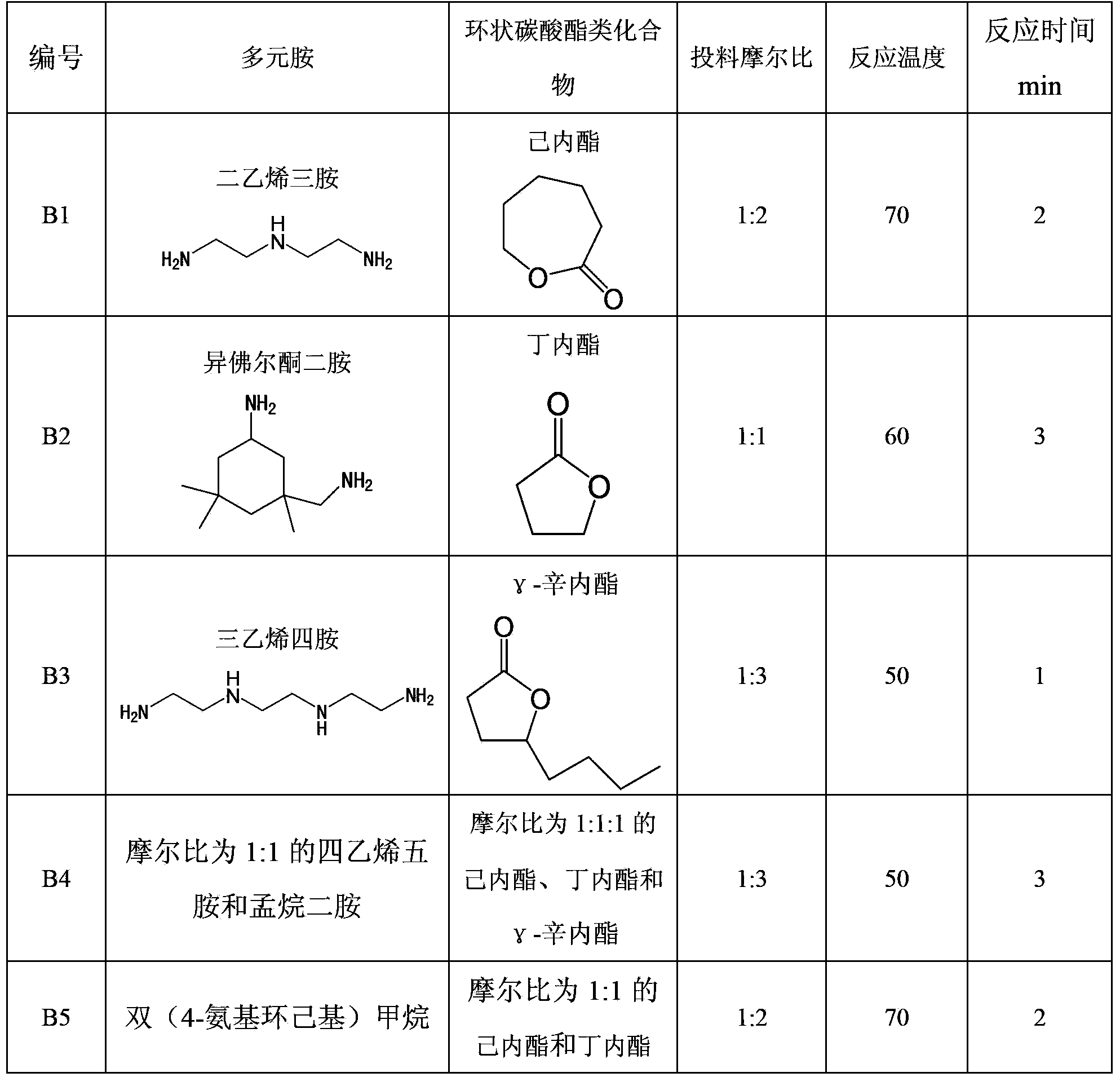

[0026] (2) Add polyamine to the flask equipped with stirring first, raise the temperature to 50-70°C, drop the lactone adduct, and drop it within 30 minutes (cool the flask with a cold water bath at the right time during the process to ensure that the whole The temperature of the system during the process is kept at the set temperature), and after the dripping is completed, the reaction is kept for 1 to 3 hours to obtain compound B; ...

Embodiment 2

[0039] Preparation of cured epoxy resin:

[0040] Using the 8 curing agents prepared in Example 1, commercially available polyamide 650 curing agent (Changsha Chemical Industry), commercially available phenolic modified T31 curing agent (Changsha Chemical Industry), diethylenetriamine (DETA) and isophorone Diamine (IPDA) was mixed with E51 epoxy resin according to the optimal reaction ratio to prepare epoxy resin cured product

[0041] The compressive strength, tensile strength, elongation, tensile elastic modulus and steel-steel tensile shear strength were tested respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com