Fiber toughening tungsten carbide welding rod

A fiber toughening, tungsten carbide technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of low binding ability of tungsten carbide particles and binders, large differences in particle size, and increased processing costs. and other problems, to achieve the effect of not easy to break and fracture, strong toughness, and firm matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

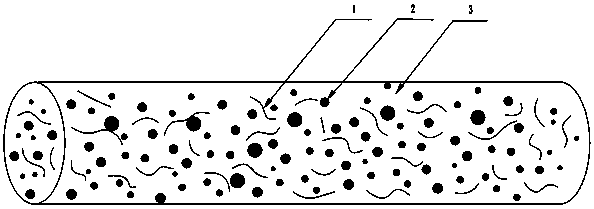

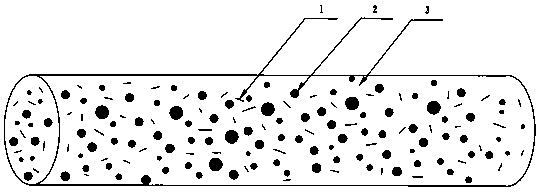

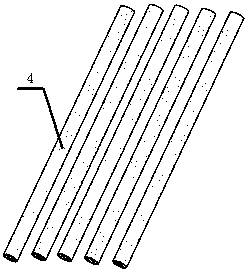

[0023] A fiber-toughened tungsten carbide electrode 4, the raw material for preparing the electrode includes the following components by mass percentage: 2wt% toughening fiber 1, 65wt% tungsten carbide particles 2, 30wt% nickel-chromium-based alloy powder 3, 3wt% sticky Binder, the toughening fiber is a mixture of 50 wt% polyacrylonitrile fibers and 50 wt% polyethylene terephthalate, and the fiber length is 500 ~ 1000 μm; the binder includes the following mass percentages Components: 13wt% PMMA, 87 wt% acetone.

[0024] The size of the tungsten carbide particles is 20-50 mesh; the size of the nickel-chromium-based alloy powder is 300 mesh, and the nickel-chromium-based alloy powder includes the following components in mass percentage: 81wt% Ni, 15wt% Cr, 1 wt% Fe, 3 wt% B.

[0025] A method for manufacturing a fiber-toughened tungsten carbide welding rod, comprising the following steps:

[0026] Step 1. Mix the toughening fiber, tungsten carbide particles, and nickel-chromiu...

Embodiment 2

[0030] A fiber-toughened tungsten carbide electrode, the raw material for preparing the electrode includes the following components by mass percentage: 4wt% toughening fiber, 65wt% tungsten carbide particles, 27wt% nickel-chromium-based alloy powder, 4wt% binder, the The toughening fiber is a mixture of 25 wt% polyacrylonitrile fiber and 75 wt% polyethylene terephthalate, and the fiber length is 500 ~ 1000 μm; the binder includes the following components in mass percentage: 15 wt% PMMA, 85 wt% acetone.

[0031] The size of the tungsten carbide particles is 20-50 mesh; the size of the nickel-chromium-based alloy powder is 300 mesh, and the nickel-chromium-based alloy powder includes the following components in mass percentage: 82wt% Ni, 7wt% Cr, 5 wt%Si, 3wt%Fe, 3wt%B.

[0032] A method for manufacturing a fiber-toughened tungsten carbide welding rod, comprising the following steps:

[0033] Step 1. Mix the toughening fiber, tungsten carbide particles, and nickel-chromium-bas...

Embodiment 3

[0037] A fiber-toughened tungsten carbide electrode, the raw material for preparing the electrode includes the following components by mass percentage: 2wt% toughening fiber, 65wt% tungsten carbide particles, 30wt% nickel-chromium-based alloy powder, 3wt% binder, the The toughening fiber is 50-200 μm silicon carbide fiber, and the fiber length is 500-1000 μm; the binder includes the following components in mass percentage: 15 wt% PMMA, 85 wt% acetone.

[0038] The size of the tungsten carbide particles is 20-50 mesh; the size of the nickel-chromium-based alloy powder is 300 mesh, and the nickel-chromium-based alloy powder includes the following components in mass percentage: 81wt%Ni, 15wt%Cr, 1wt% %Fe, 3 wt% B.

[0039] A method for manufacturing a fiber-toughened tungsten carbide welding rod, comprising the following steps:

[0040] Step 1. Mix the toughening fiber, tungsten carbide particles, and nickel-chromium-based alloy powder to form a powder for the electrode matrix, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com