A kind of acid silicone sealant and preparation method thereof

A sealant, acid silicone technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems affecting the product quality of acid silicone sealants, low production efficiency, and products with skinning, etc. Better compatibility, higher strength, and less skinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

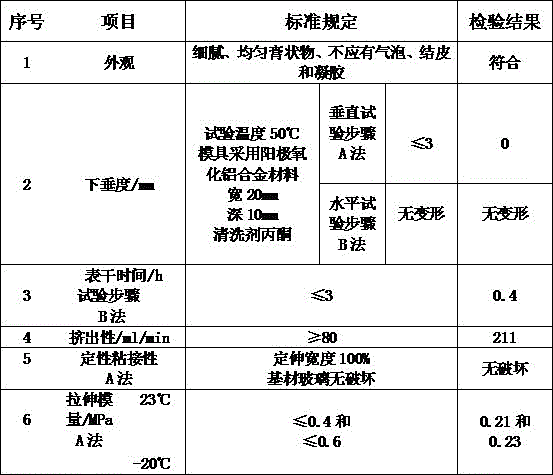

Examples

Embodiment 1

[0031] A kind of acidic silicone sealant is prepared by the following steps:

[0032] 1) Take the following components by weight: 200 parts of 107 glue, 120 parts of 330 silicone oil (the viscosity of 330 silicone oil is 100-5500 centipoise), 20 parts of fumed silica (the moisture content of fumed silica is less than 1%), 10 parts of crosslinking agent (including 7 parts of methyltriacetylsilane and 3 parts of methyldiacetylsilane), 5 parts of thixotropic agent (polyether modified silicone oil), 0.09 parts of catalyst (tin acetate);

[0033] 2) Add 200 parts of 107 glue and 5 parts of thixotropic agent to the glue tank, vacuumize and stir for 3 to 5 minutes;

[0034] 3) After step 2) the stirring is stopped, open the pumping valve to suck 10 parts of cross-linking agent into the glue tank, close the pumping valve, start stirring, keep the vacuum degree -0.09~-0.1MPa, first stir at low speed for 5~10 minutes , and then stir at high speed for 5 to 10 minutes;

[0035] 4) After...

Embodiment 2

[0041] A kind of acidic silicone sealant is prepared by the following steps:

[0042] 1) Take the following components by weight: 205 parts of self-produced 107 glue, 125 parts of 330 silicone oil (the viscosity of 330 silicone oil is 100-5500 centipoise), 25 parts of fumed silica (the moisture content of fumed silica is less than 1%) 15 parts of crosslinking agent (including 10 parts of methyltriacetylsilane and 5 parts of methyldiacetylsilane), 6 parts of thixotropic agent (polyether modified silicone oil), 0.12 parts of catalyst (tin acetate).

[0043] 2) Add 205 parts of 107 glue and 6 parts of thixotropic agent to the glue tank, vacuumize and stir for 3 to 5 minutes;

[0044] 3) After step 2) the stirring is stopped, open the pumping valve to inhale 15 parts of cross-linking agent, close the pumping valve, start stirring, keep the vacuum degree -0.09~-0.1MPa, stir at low speed for 5 to 10 minutes, then stir at high speed for 5 minutes ~10 minutes;

[0045] 4) After the ...

Embodiment 3

[0051] A kind of acidic silicone sealant is prepared by the following steps:

[0052]1) Take the following components by weight: 220 parts of self-produced 107 glue, 130 parts of 330 silicone oil (the viscosity of 330 silicone oil is 100-5500 centipoise), 30 parts of fumed silica (the moisture content of fumed silica is less than 1%) 20 parts of crosslinking agent (15 parts of methyltriacetylsilane and 5 parts of methyldiacetylsilane), 4 parts of thixotropic agent (polyether modified silicone oil), 0.15 parts of catalyst (tin acetate).

[0053] 2) Add 220 parts of 107 glue and 4 parts of thixotropic agent to the glue tank, vacuumize and stir for 3 to 5 minutes;

[0054] 3) After step 2) the stirring is stopped, open the pumping valve to inhale 20 parts of cross-linking agent, close the pumping valve, start stirring, and keep the vacuum degree -0.09~-0.1MPa, stir at low speed for 5 to 10 minutes, then stir at high speed for 5 minutes ~10 minutes;

[0055] 4) After the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com