Sealant with neutral and transparent silicone structure

A sealant and transparent technology, applied in the direction of adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor bonding performance of substrates, low strength, low hardness, and inability to use, so as to ensure long-term safety. Effects of improving strength and hardness and increasing filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

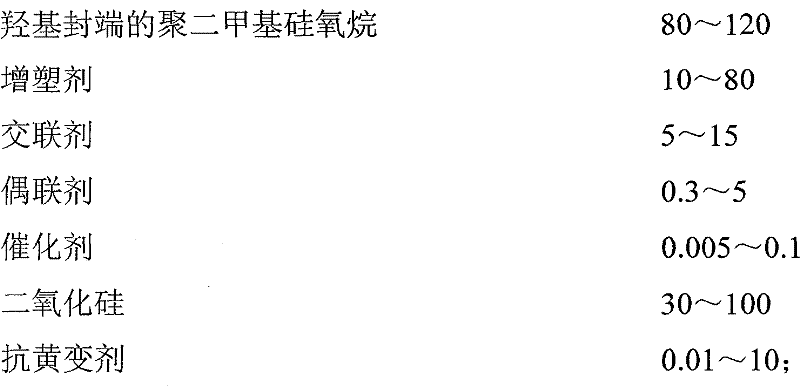

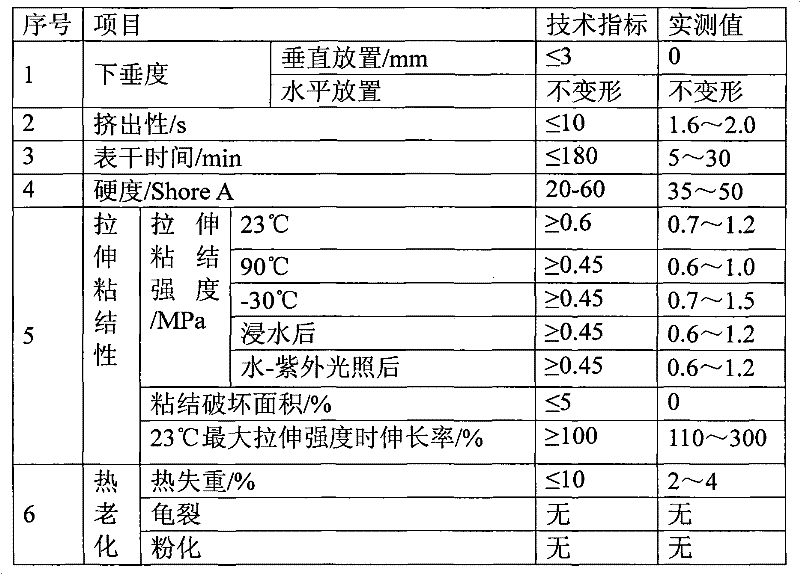

[0034] The neutral transparent silicone structural sealant of the present invention is composed of the following components by weight:

[0035] Hydroxy-terminated polydimethylsiloxane:

[0036] 10000cp 10

[0037] 300000cp 70

[0038] Plasticizer: methyl silicone oil 20

[0039] Crosslinking agent:

[0040] Methyltributanoximinosilane 2.0

[0041] Vinyl tributylketoxime silane 3.6

[0042] Coupling agent: Aminopropyltrimethoxysilane 0.48

[0043] Catalyst: Dibutyltin diacetate 0.006

[0044] Fumed silica:

[0045] 60m 2 / g 15

[0046] 190m 2 / g 15

[0047] UV absorber: 2,4,6-tris(2'-butoxyphenyl)-1,3,5-triazine 0.05

[0048] Mix the above raw materials uniformly according to the conventional method to obtain a neutral transparent silicone structural sealant.

Embodiment 2

[0050] Transparent silicone structural sealant of the present invention, it is made up of following components by weight:

[0051] Hydroxy-terminated polydimethylsiloxane:

[0052]5000cp 30

[0053] 500000 cp 70

[0054] Plasticizer: ethyl silicone oil 50

[0055] Crosslinking agent:

[0056] Methyltributanoximinosilane 5.0

[0057] Dimethyldibutylketoximosilane 5.0

[0058] Coupling agent: mercaptopropyltriethyl / methoxysilane 3.0

[0059] Catalyst: Dibutyltin diacetate 0.5

[0060] Fumed silica:

[0061] 150m 2 / g 23.6

[0062] 170m 2 / g 16.4

[0063] Light stabilizer: 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 0.2

[0064] Mix the above raw materials uniformly according to the conventional method to obtain a neutral transparent silicone structural sealant.

Embodiment 3

[0066] Transparent silicone structural sealant of the present invention, it is made up of following components by weight:

[0067] Hydroxy-terminated polydimethylsiloxane:

[0068] 20000cp 90

[0069] 200000 cp 10

[0070] Plasticizer: phenyl silicone oil 70

[0071] Crosslinking agent:

[0072] Vinyltributanoximinosilane 3.0

[0073] Dimethyldibutylketoximosilane 7.0

[0074] Coupling agent:

[0075] Mercaptopropyltriethyl / Methoxysilane 1.0

[0076] γ-(2.3 Glycidoxy)propyltrimethoxysilane 1.0

[0077] γ-(Methacryloyloxy)propyltrimethoxysilane 1.0

[0078] Catalyst: Dibutyltin dilaurate 0.08

[0079] Precipitated silica 50

[0080] Light stabilizer: hexamethylphosphoric triamide, tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite 5.0

[0081] Mix the above raw materials uniformly according to the conventional method to obtain a neutral transparent silicone structural sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com