Polysulfide rubber modified epoxy resin anti-corrosion and anti-sewage coating, and preparation method and system thereof

A technology of epoxy resin and polysulfide rubber, used in epoxy resin coatings, antifouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of poor data control accuracy, poor safety, and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

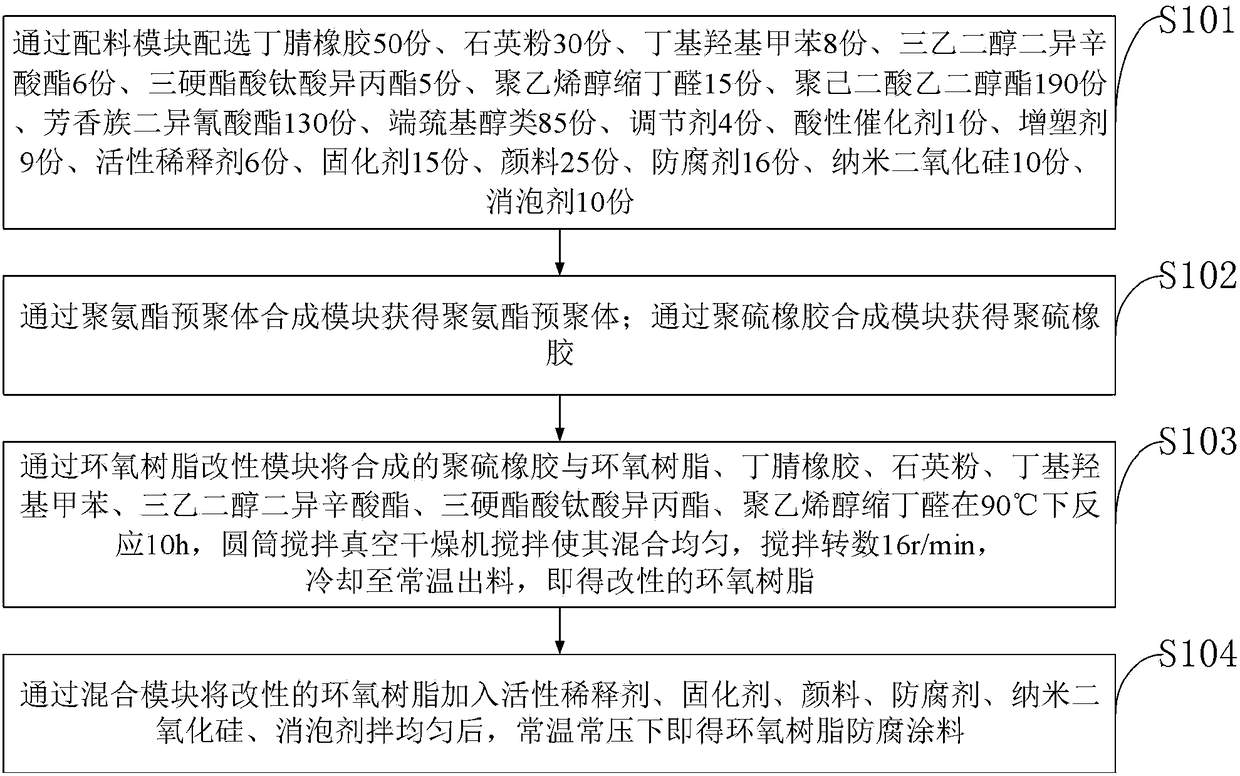

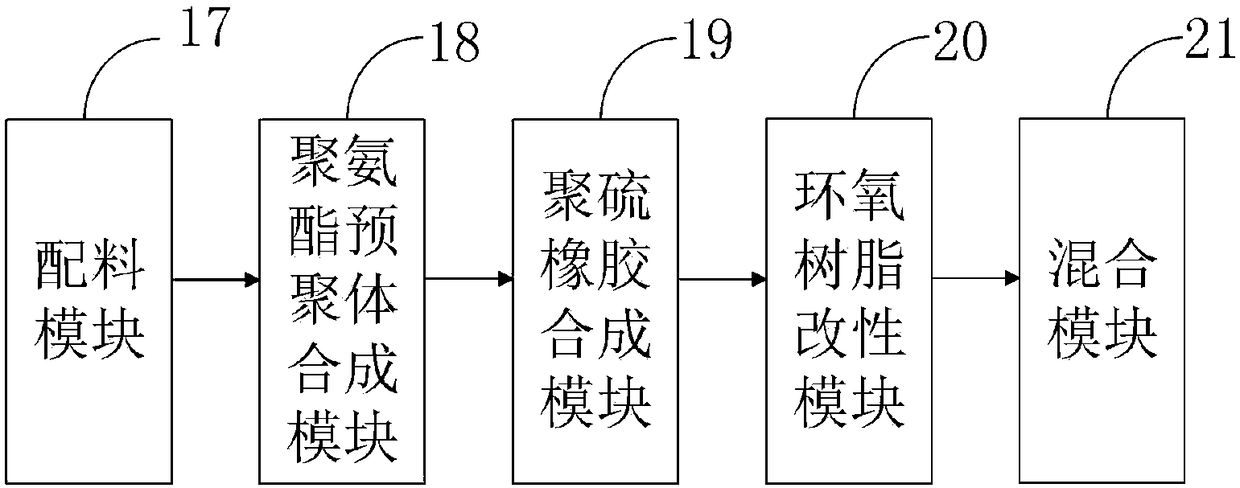

[0103] Such as figure 1 As shown, the polysulfide rubber modified epoxy resin anticorrosion and anti-pollution paint preparation method provided by the embodiment of the present invention comprises the following steps:

[0104] S101, 50 parts of nitrile rubber, 30 parts of quartz powder, 8 parts of butylated hydroxytoluene, 6 parts of triethylene glycol diisocaprylate, 5 parts of isopropyl titanate tristearate, and poly 15 parts of vinyl butyral, 190 parts of polyethylene adipate, 130 parts of aromatic diisocyanate, 85 parts of terminal mercapto alcohols, 4 parts of regulator, 1 part of acid catalyst, 9 parts of plasticize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com