A special coating for modified epoxy denitrification device and its preparation method

A modification and coating technology, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of low cost of modified epoxy coatings, high cost of pure epoxy coatings, and complicated construction processes, and achieve durable Improved environmental stress cracking performance, good fullness, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

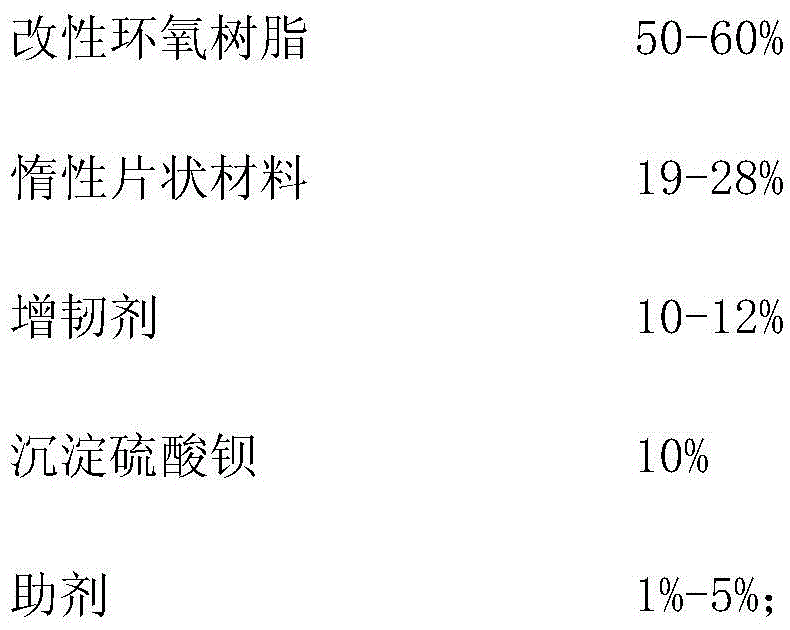

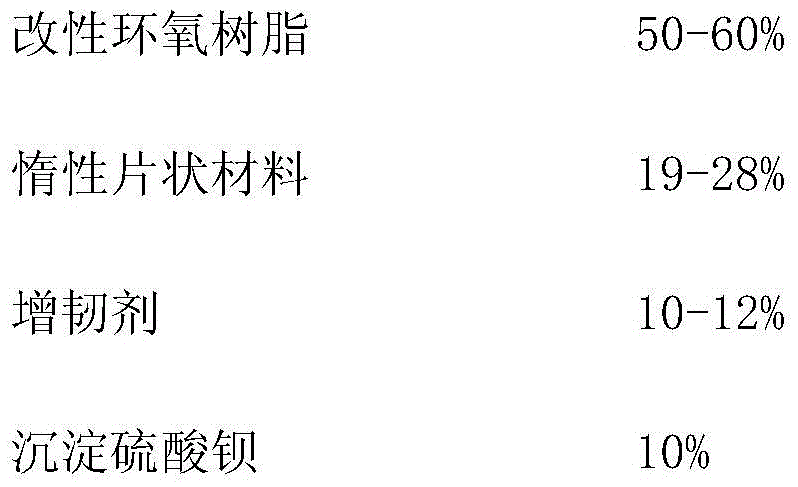

[0050] A special coating for modified epoxy denitrification devices provided in this example, the coating includes two components, A and B, and the weight ratio of component A to component B is 5:1;

[0051] A component includes the following components by mass percentage, 50% modified epoxy resin, 25% 500 mesh graphite flakes, 11% polyamide, 10% precipitated barium sulfate, 4% additives;

[0052] Component B includes the following ingredients by mass percentage, 40% curing agent and 60% solvent;

[0053] Among them, the modified epoxy resin is composed of 76% epoxy resin, 5% epoxypropyl trimethoxysilane, 9% polyamide, 2% benzyl dimethylamine benzyl triethyl ammonium chloride and 8% polyurethane prepolymer composition;

[0054] In this embodiment, the auxiliary agent is a silicon-based polymerizing agent and a reactive diluent mixed at a ratio of silicon-based polymerizing agent: reactive diluent = 1:1.

[0055] In this embodiment, the curing agent is a modified polyamide cu...

Embodiment 2

[0069] A special coating for a modified epoxy denitrification device provided in this example, the coating includes two components, A and B, and the weight ratio of component A to component B is 5.5:1;

[0070] Component A includes the following components by mass percentage, 59% of modified epoxy resin, 19% of 500 mesh graphite flakes, 10% of polyamide, 10% of precipitated barium sulfate, and 2% of additives;

[0071] Component B includes the following ingredients by mass percentage, 35% curing agent and 65% solvent;

[0072] Among them, the modified epoxy resin is composed of 80% epoxy resin, 4% epoxypropyltrimethoxysilane, 8% polyamide, 1% benzyldimethylamine benzyltriethyl ammonium chloride and 7% polyurethane prepolymer composition;

[0073] In this embodiment, the auxiliary agent is a silicon-based polymerizing agent and an additive, which are mixed at a ratio of silicon-based polymerizing agent: additive = 1:1.

[0074] In this embodiment, the curing agent is a modifi...

Embodiment 3

[0088]A special coating for modified epoxy denitration devices provided in this example, the coating includes two components, A and B, and the weight ratio of component A to component B is 6:1;

[0089] Component A includes the following components by mass percentage, 55% of modified epoxy resin, 20% of 500 mesh graphite flakes, 12% of polyazelaic anhydride, 10% of precipitated barium sulfate, and 3% of additives;

[0090] Component B includes the following ingredients by mass percentage, 45% curing agent and 55% solvent;

[0091] Among them, the modified epoxy resin is composed of 75% epoxy resin, 6% epoxypropyltrimethoxysilane, 10% polyamide, 1% benzyldimethylamine benzyltriethyl ammonium chloride and 8% polyurethane prepolymer composition;

[0092] In this embodiment, the auxiliary agent is silicon-based polymerizing agent, additive and reactive diluent, which are mixed according to the ratio of silicon-based polymerizing agent: additive: reactive diluent = 1:1:.

[0093]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com