A kind of interior wall plastering mortar and its construction method

A plastering mortar and interior wall technology, applied in the field of construction mortar, can solve problems such as flying environment, large deformation stress of plastering interface, pollution, etc., and achieve the effect of saving natural mineral resources, improving bonding strength, and increasing mortar voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

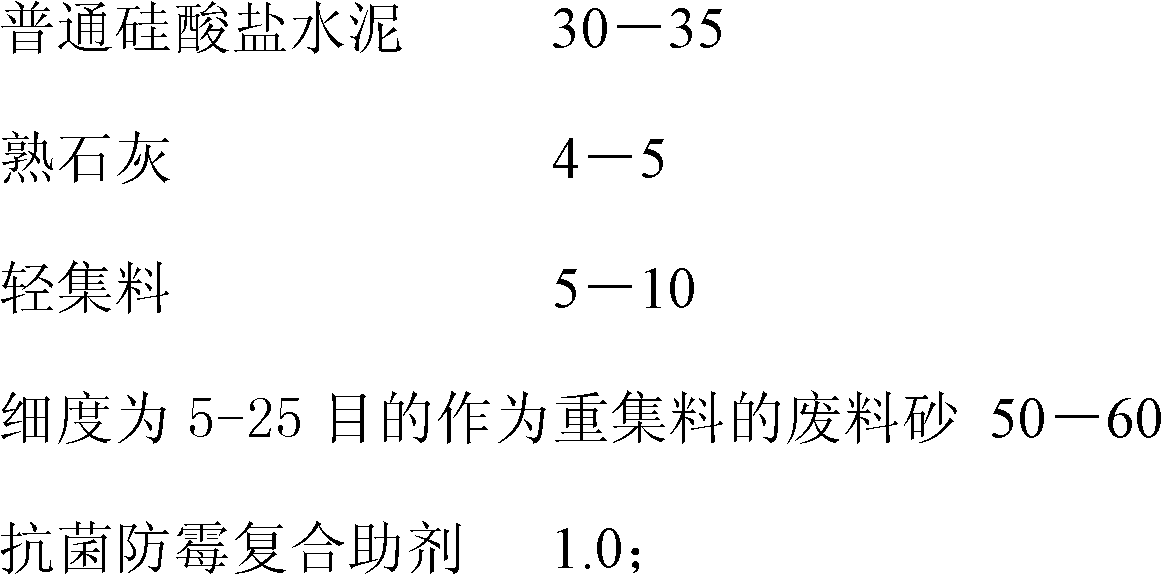

Method used

Image

Examples

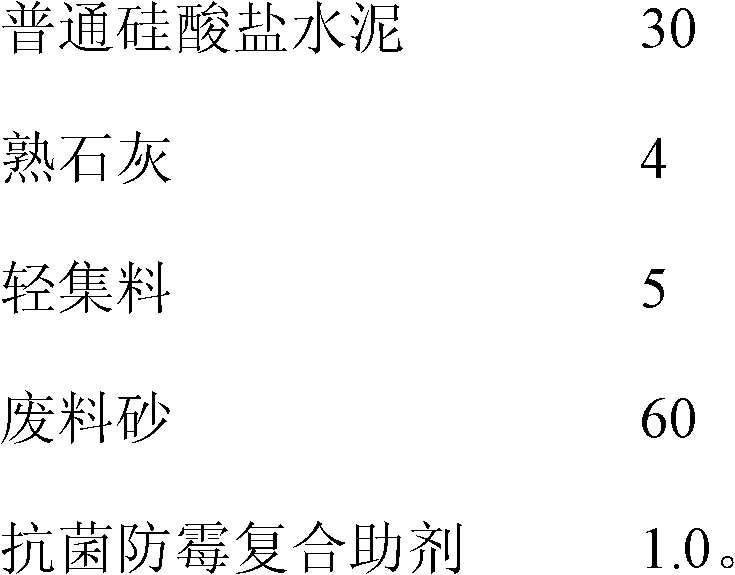

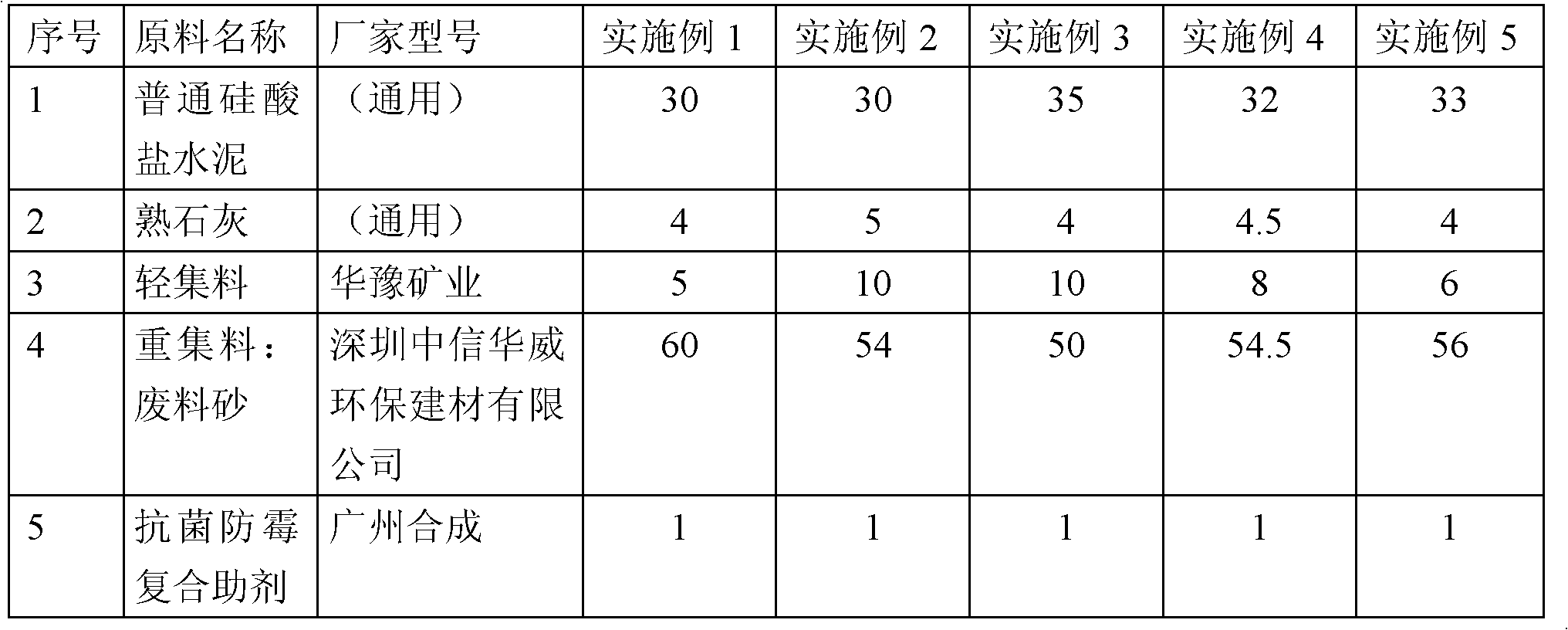

Embodiment 1

[0032] The production technology of interior wall plastering mortar of the present invention is as follows:

[0033] Take each component according to the weight shown in Example 1 in Table 1, and the production process is as follows: ordinary Portland cement, slaked lime, light aggregate, heavy aggregate and antibacterial and anti-mildew composite auxiliary agent are mixed according to the above-mentioned specific gravity, and mechanically stirred Evenly, promptly obtain the interior wall plastering mortar of embodiment 1, all can with paper bag packing or bulk.

[0034] Construction method: get 100 kilograms of the interior wall plastering mortar of the embodiment 1 obtained above, add 30 kilograms of water to dilute, mechanically or manually stir until mixing evenly, reach the viscosity that is suitable for mechanical spraying or manual construction (use interior wall in the prior art Mortar experience viscosity) can be mechanized spraying or manual work.

[0035] Perform p...

Embodiment 2

[0037] Obtain the interior wall plastering mortar of embodiment 2 with the weight of each component in the embodiment 2 specified in table 1, repeat the production process described in embodiment 1 (only the weight of each component changes); repeat the construction in embodiment 1 The method is to take 100 kg of mortar and add 35 kg of water to dilute it, stir it mechanically or manually until it is evenly mixed, and then carry out mechanized spraying or manual operation. Perform performance testing with each standard described in Example 1, and the results are as shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0039] Obtain the interior wall plastering mortar of embodiment 3 with the weight of each component in the embodiment 3 specified in table 1, repeat the production process described in embodiment 1 (only the weight of each component changes); repeat the construction in embodiment 1 The method is to take 100 kg of mortar and add 40 kg of water to dilute it, stir it mechanically or manually until it is evenly mixed, and then carry out mechanized spraying or manual operation. Perform performance testing with each standard described in Example 1, and the results are as shown in the corresponding data of Example 3 in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com