vacuum equipment

A vacuuming equipment, low vacuum technology, applied in mechanical equipment, liquid variable capacity machinery, pump control and other directions, can solve the problems of inability to guarantee the yield, reduce system sealing, system air leakage, etc. The effect of cleaning and cleaning, unobstructed gas flow, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

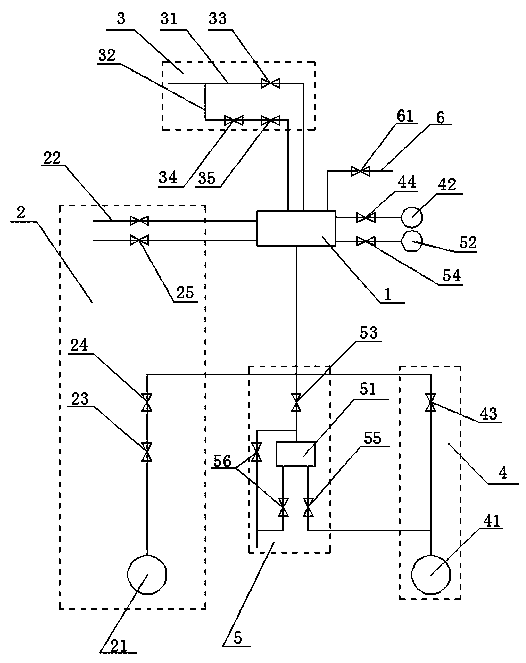

[0024] like figure 1 As shown, the vacuum equipment of the present invention includes a vacuum chamber 1, a process system 2, a vacuum breaking system 3, a low vacuum system 4 and a high vacuum system 5, and the low vacuum system 4 includes a first low vacuum pump 41 and a low vacuum pump 41. meter 42, the first low-vacuum pump 41 and the low-vacuum gauge 42 are connected to the vacuum chamber 1 through pipelines, and a first electromagnetic valve 43 is arranged between the first low-vacuum pump 41 and the vacuum chamber 1, A first isolation valve 44 is provided between the low vacuum gauge 42 and the vacuum chamber 1;

[0025] The high vacuum system 5 includes a high vacuum pump 51 and a high vacuum gauge 52, the high vacuum pump 51 and the high vacuum gauge 52 are all connected to the vacuum chamber 1 through pipelines, and the high vacuum pump 51 is connected to the vacuum chamber 1 A second solenoid valve 53 is arranged between them, a second isolation valve 54 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com