Air-dried unsaturated polyester resin and production method thereof

A technology of polyester resin and production method, which is applied in the field of air-drying unsaturated polyester resin and its production, can solve the problems of poor air-drying property, less paraffin consumption, and difficulty in controlling, and achieve convenient grinding and polishing, and improve air-drying Sexuality, the effect of increasing transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Take the production of air-drying unsaturated polyester resin with 3600 liters of reactor as an example

[0035] raw material

[0036] Reaction feed A

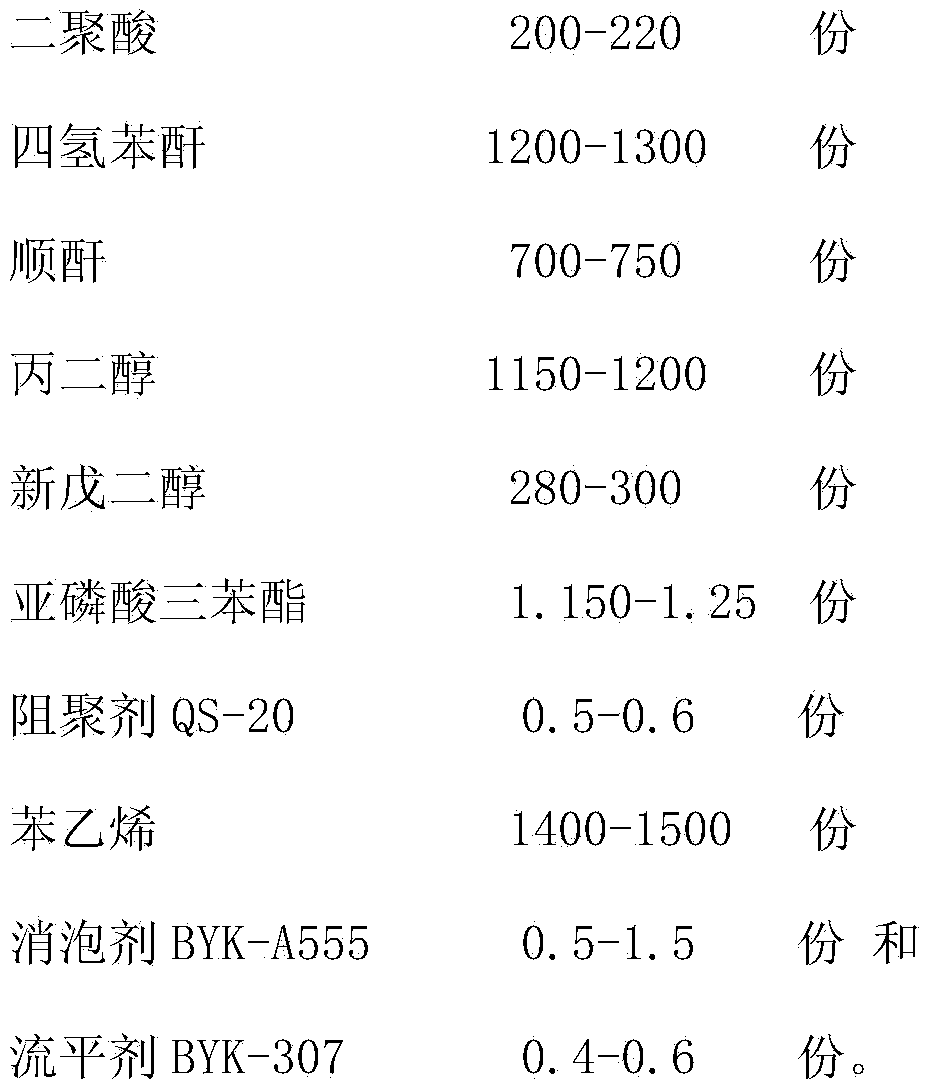

[0037]

[0038] Cooling, dilution step feeding B

[0039]

[0040] production steps

[0041] 1. Check equipment, pipelines, electrical appliances, instruments, and check the type and quantity of raw materials.

[0042] 2. Put the reaction materials A into the reaction kettle: glycol, dibasic acid (anhydride), triphenyl phosphite and QS-20, etc. Heat up, 10 degrees / hour, stir after 0.5 hours, when the material heats up When the temperature reaches 120°C, start the reaction stirrer and supply 4M nitrogen 3 / h and continue to heat up the reaction.

[0043] 3. When the temperature of the distillation head rises to 98-100°C, the vertical condenser is supplied with water, the temperature of the distillation head is controlled at 100-102°C, and the reaction is kept for 1 hour after the water is discharg...

Embodiment 2

[0061] Embodiment 2 Take the production of air-drying unsaturated polyester resin with 3600 liters of reactor as an example

[0062] raw material

[0063] Reaction feed A

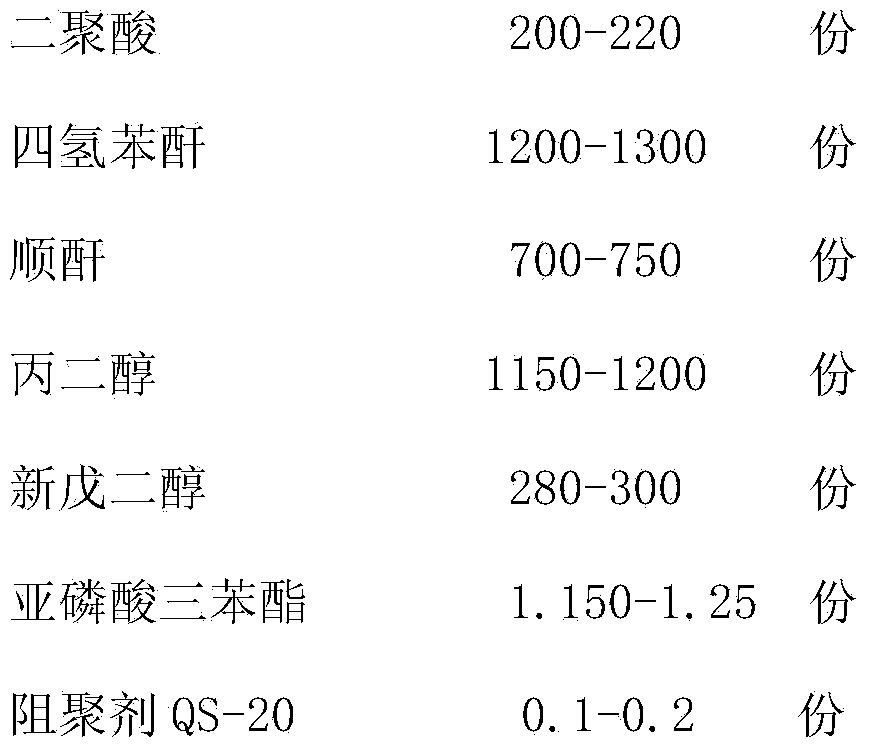

[0064]

[0065] Cooling, dilution step feeding B

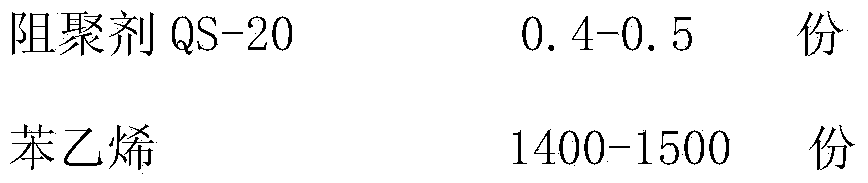

[0066]

[0067] production steps

[0068]1. Check equipment, pipelines, electrical appliances, instruments, and check the type and quantity of raw materials.

[0069] 2. Put the reaction materials A into the reaction kettle: glycol, dibasic acid (anhydride), triphenyl phosphite and QS-20, etc. Heat up, stir after 0.5 hours, 10 degrees / hour, when the material heats up When the temperature reaches 120°C, start the reaction stirrer and supply 4M nitrogen 3 / h and continue to heat up the reaction.

[0070] 3. When the temperature of the distillation head rises to 98-100°C, the vertical condenser is supplied with water, the temperature of the distillation head is controlled at 100-102°C, and the reaction is kept for 1 hour after the water is discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com