Lifting type flat stone grinding, polishing and polishing device

A processing device and hoisting technology, which is applied to grinding drive devices, grinding/polishing equipment, and surface polishing machine tools, etc., can solve the problems of high equipment cost, time and energy consumption, and cumbersome small batch tasks, and achieve low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

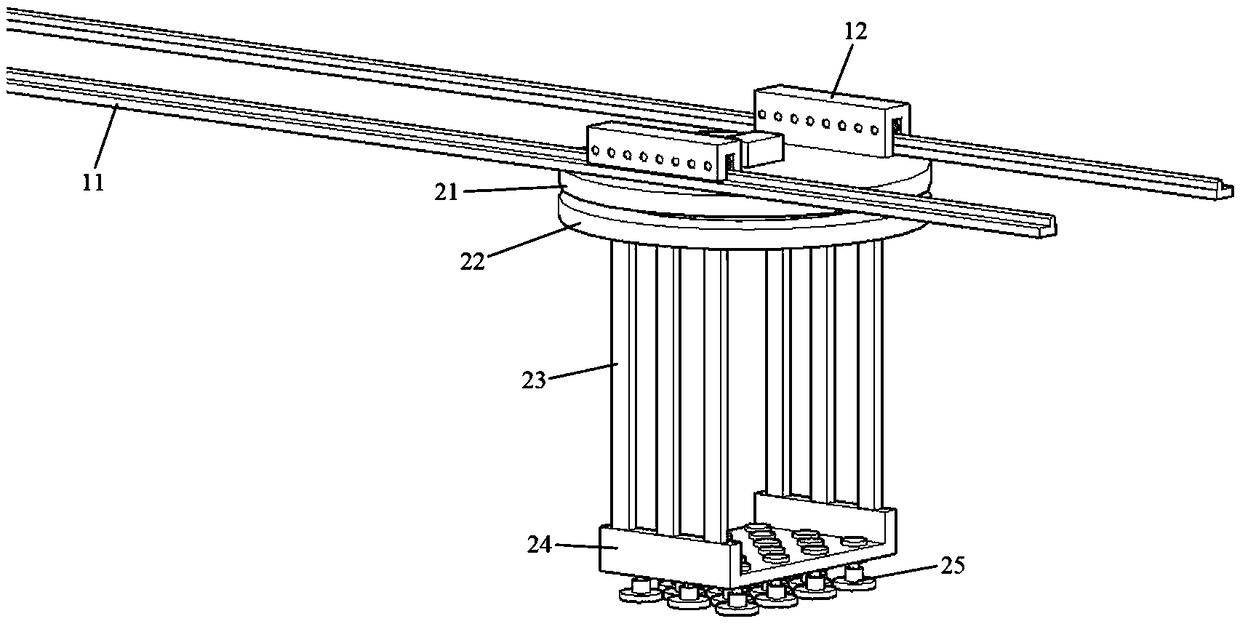

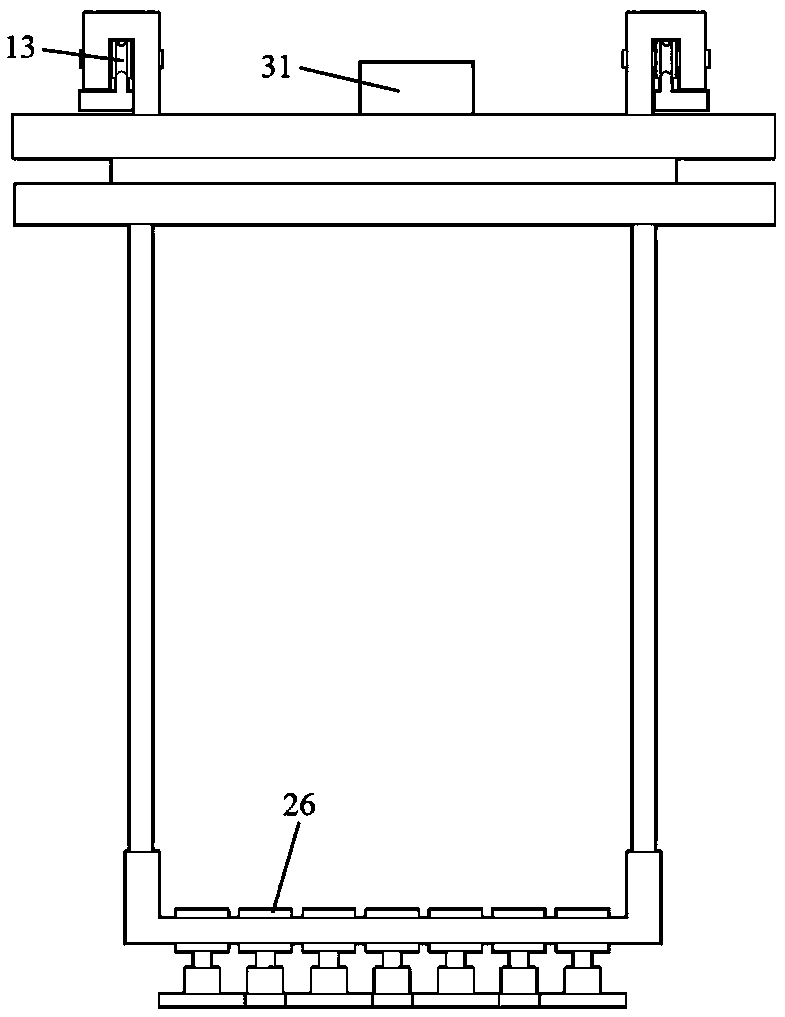

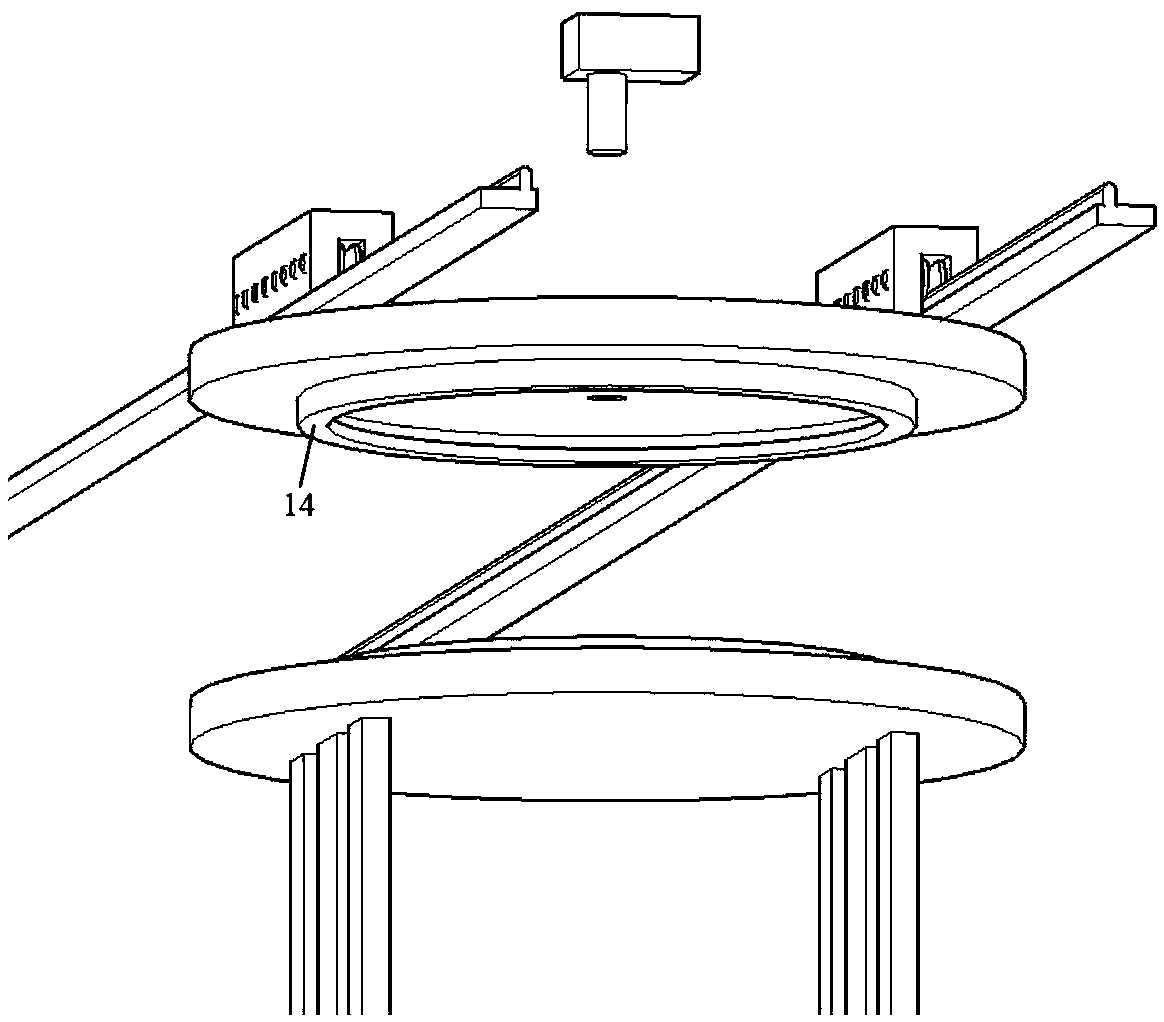

[0022] Such as Figure 1 to Figure 4 The shown hoisting type planar stone grinding and polishing processing device includes a guide rail 11 and a moving block 12; the moving block 12 is installed on the guide rail 11, and the guide rails 11 are fixed in parallel, and the front section of the moving block 12 is an inverted U Type, the pulley 13 is housed in the moving block 12 and is mounted on the guide rail 11, the end of the moving block 12 is fixed on the upper surface of the upper wheel 21, the lower wheel 22 is rotatably fixed under the upper wheel 21, and the lower wheel 22 is vertically fixed There is a connecting rod 23, the lower end of the connecting rod 23 is fixed on the fixed block 24, the front section of the fixed block 24 is U-shaped, the connecting rod 23 is fixed on the upper end of the fixed block 24, the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com