Alkali-free substrate glass and thinning method thereof

A glass thinning and alkali-free technology, which is applied in the direction of manufacturing tools, grinding devices, grinding machine tools, etc., can solve the problems of uneven glass surface etching, glass surface roughness, and affecting product performance, so as to achieve the effect of improvement and realize the glass Thickness, wettability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

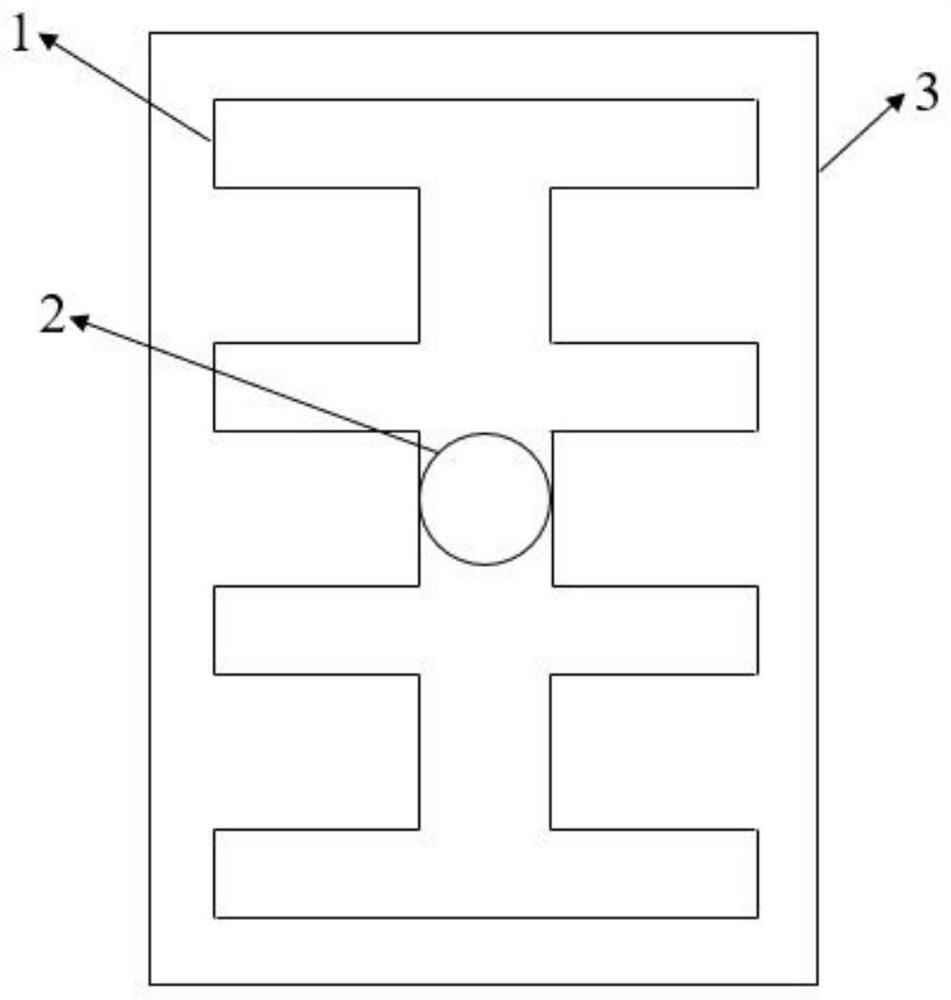

Image

Examples

Embodiment 1

[0035] A kind of alkali-free substrate glass, by mass percentage, comprises the following components: 60.4% SiO 2 , 17.1% Al 2 o 3 , 12.8% B 2 o 3 , 1.4% MgO, 6.7% CaO, 1.2% SrO, 0% BaO, and 0.1% SnO 2 .

[0036] The alkali-free substrate glass with a thickness of 0.7mm is prepared by the preparation method of the alkali-free substrate glass of the present invention.

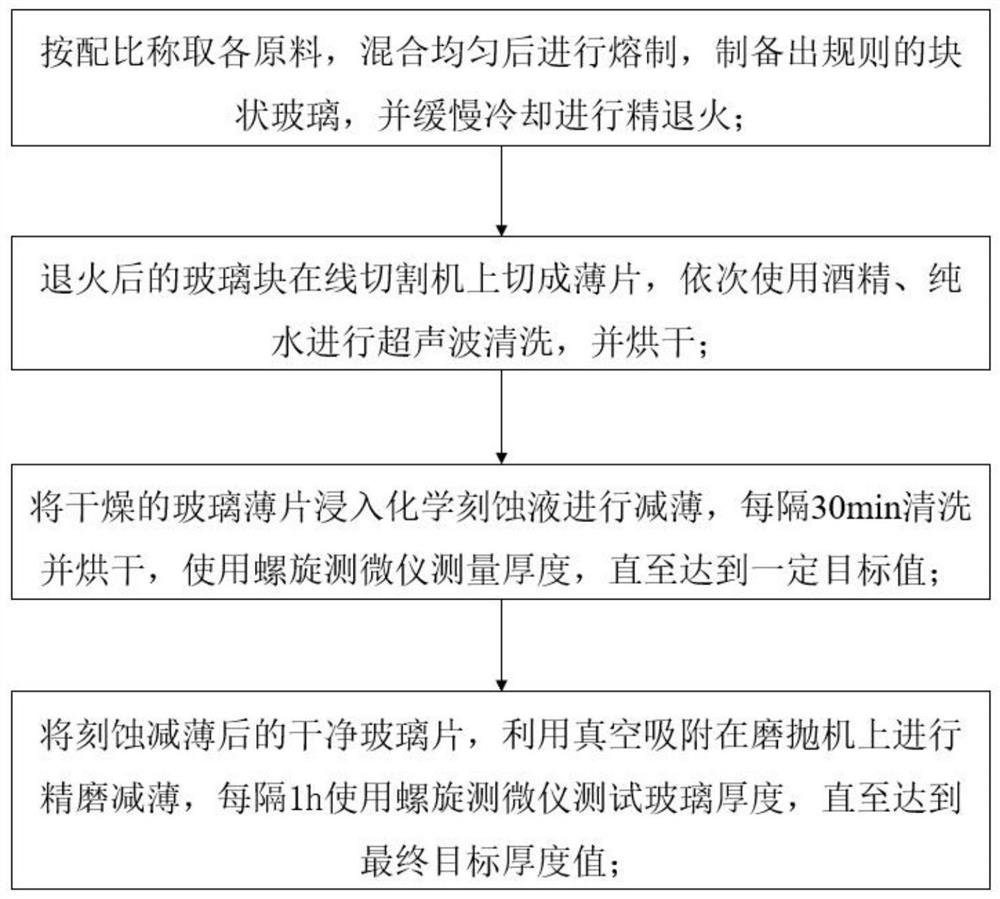

[0037] A method for thinning the non-alkali substrate glass, the non-alkali substrate glass in the present embodiment is thinned by the following steps,

[0038] S1: Thinning by chemical etching: immerse the alkali-free substrate glass in this embodiment into a chemical etching solution containing 25% hydrofluoric acid, 10% glacial acetic acid, and 3% sodium dodecylsulfonate Corrode in medium for 30min, take out the non-alkali substrate glass, use alcohol and pure water for ultrasonic cleaning and drying, use a spiral micrometer to measure the thickness until the thickness of the glass sheet reaches 0.5mm....

Embodiment 2

[0042] A kind of alkali-free substrate glass, by mass percentage, comprises the following components: 61.2% SiO 2 , 18.4% Al 2 o 3 , 10.3% B 2 o 3 , 1.4% MgO, 7.5% CaO, 1.0% SrO, 0% BaO, and 0.2% SnO 2 .

[0043] The alkali-free substrate glass with a thickness of 0.7mm is prepared by the preparation method of the alkali-free substrate glass of the present invention.

[0044] A method for thinning the non-alkali substrate glass, the non-alkali substrate glass in the present embodiment is thinned by the following steps,

[0045] S1: Thinning by chemical etching: immerse the alkali-free substrate glass in this embodiment in a chemical etching solution containing 27% hydrofluoric acid, 11.5% glacial acetic acid, and 3.2% sodium dodecyl sulfate After eroding for 28.5 minutes, take out the alkali-free substrate glass, clean and dry it ultrasonically with alcohol and pure water, repeat step S1 once, and measure the thickness with a spiral micrometer until the thickness of the ...

Embodiment 3

[0049] A kind of alkali-free substrate glass, by mass percentage, comprises the following components: 60.8% SiO 2 , 18.3% Al 2 o 3 , 4.3% B 2 o 3 , 1.9% MgO, 4.1% CaO, 2.1% SrO, 8.3% BaO, and 0.2% SnO 2 .

[0050] The alkali-free substrate glass with a thickness of 0.7mm is prepared by the preparation method of the alkali-free substrate glass of the present invention.

[0051] A method for thinning the non-alkali substrate glass, the non-alkali substrate glass in the present embodiment is thinned by the following steps,

[0052] S1: Thinning by chemical etching: the alkali-free substrate glass in this embodiment is immersed in a chemical etching solution containing 26.8% hydrofluoric acid, 12% glacial acetic acid, and 3.8% sodium dodecylbenzenesulfonate. Corrode in the solution for 27 minutes, take out the alkali-free substrate glass, use alcohol and pure water for ultrasonic cleaning and drying, and use a spiral micrometer to measure the thickness until the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com