Automatic cable insulation layer polishing machine

A cable insulation and grinding machine technology, which is applied to the parts of grinding machine tools, grinding machines, abrasive belt grinding machines, etc., can solve the problems of uneven grinding, high labor intensity, low efficiency, etc., achieve high grinding quality, reduce labor intensity, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

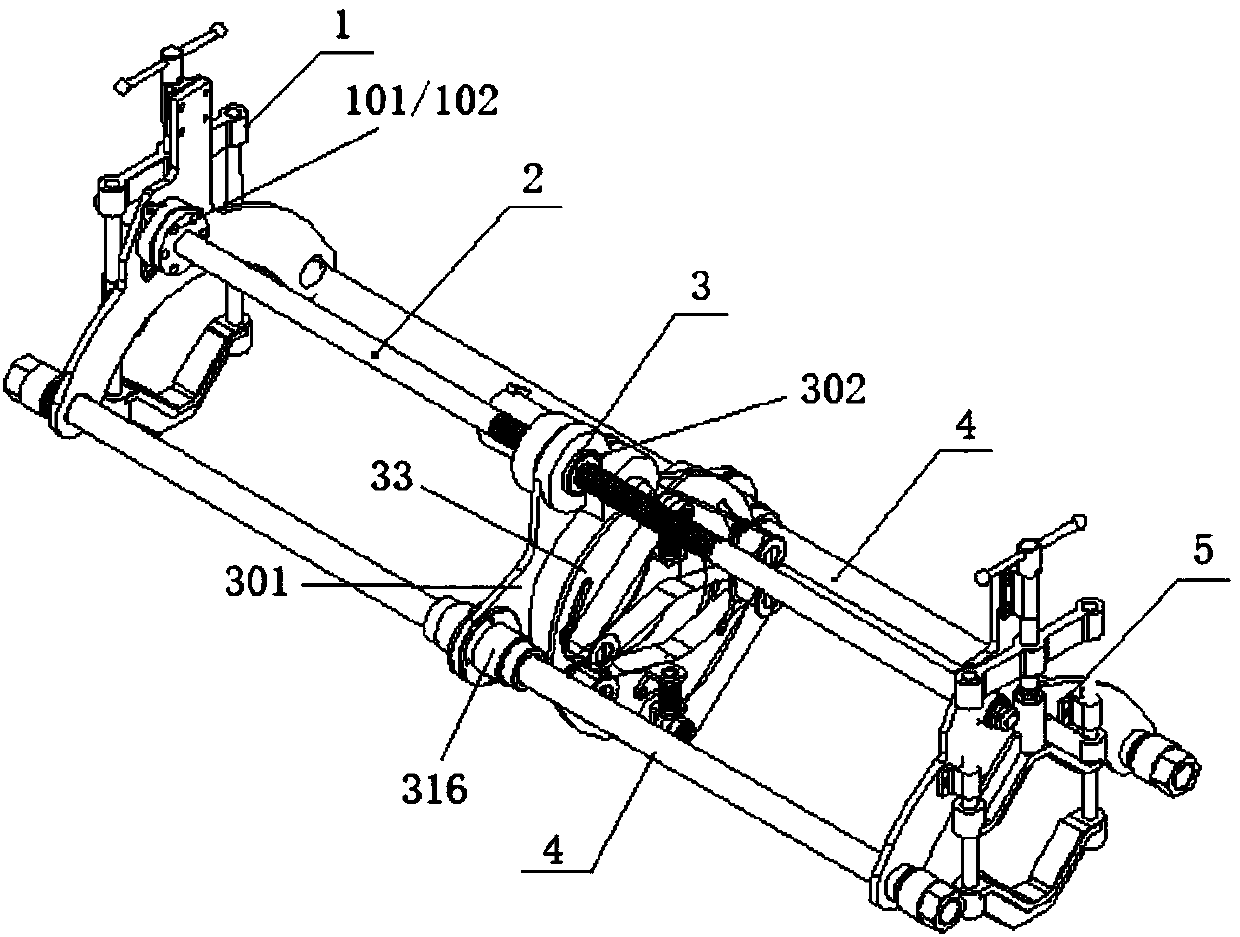

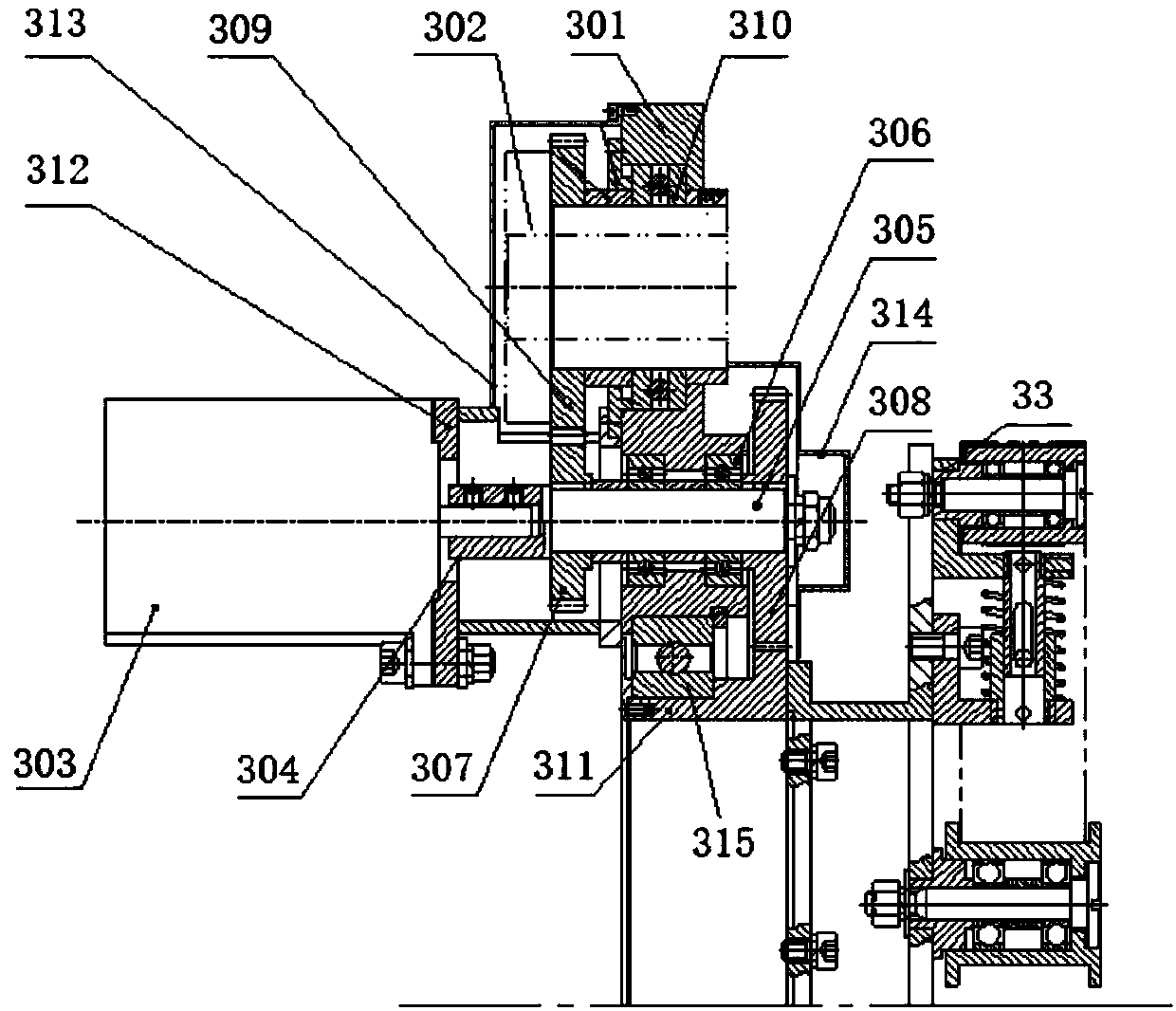

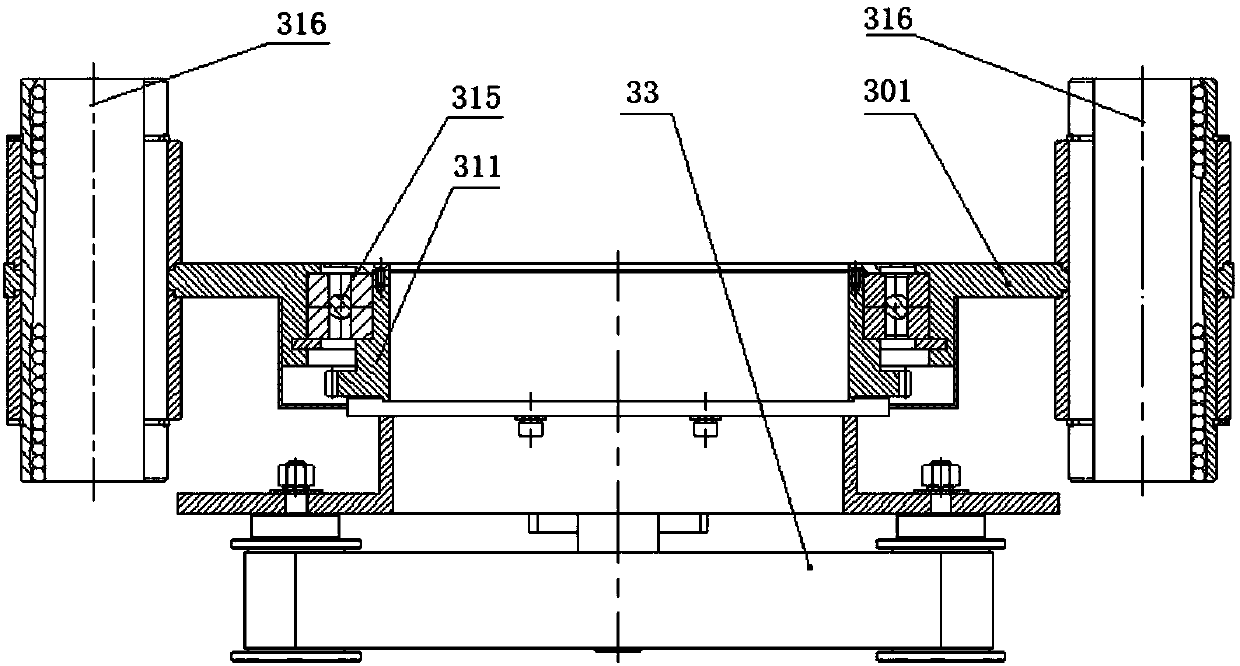

[0044] see figure 1 , an automatic cable insulation grinding machine in the illustration is a preferred solution of the present invention, specifically including a first clamping device 1, a driving screw 2, a grinding device 3, a reciprocating guide rod 4 and a second clamping device 5. Part, wherein the first clamping device 1 and the second clamping device 5 are respectively used to clamp the two ends of the cable to be polished, and the driving screw 2 and the two reciprocating guide rods 4 are parallel to each other and fixedly connected respectively Between the first clamping device 1 and the second clamping device 5, a grinding drive nut 302 and a grinding guide cylinder 316 are arranged on the grinding device 3, and the grinding drive nut 302 is assembled on the grinding screw mandrel 2, and the grinding drive nut and The thread transmission between the grinding screw rods realizes the back and forth axial movement and grinding of the grinding device 3 , and the grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com