Special polishing liquid for diamond compact and preparation method of special polishing liquid

A diamond composite sheet, grinding and polishing technology, applied in the field of special grinding and polishing liquid, can solve the problems of grinding and polishing lines, inability to process, and difficulty in achieving the effect of mirror grinding and polishing, and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] ⑴Implementation conditions

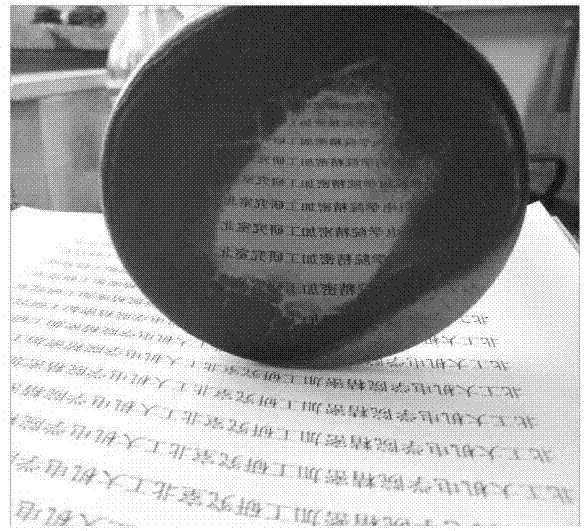

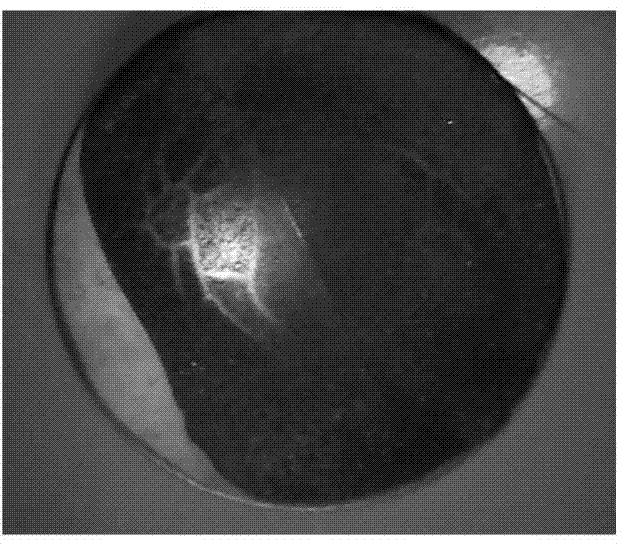

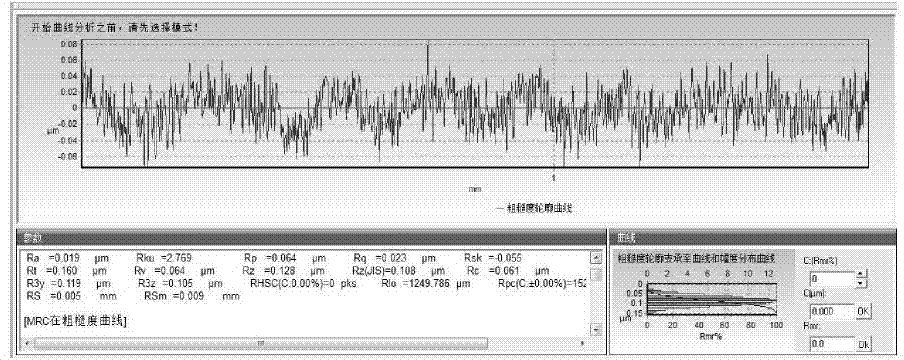

[0026] Experimental equipment: BDE-1B frequency conversion and speed regulation optical two-axis grinding and polishing machine, Beijing Times surface roughness measuring instrument TR300, image acquisition microscope + Panasonic WV-CP460, S-3400NⅡ scanning electron microscope;

[0027] Polishing conditions: ambient temperature is room temperature, special diamond polishing liquid, diamond composite sheet workpiece, special silk polishing pad;

[0028] The polishing parameters are: the speed of the polishing disc is 80-180r / min, and the polishing pressure is 0.4-0.7KN / cm 2 , the polishing eccentricity is 35mm, the frequency is 16-20Hz, and the polishing time is 40-60min.

[0029] ⑵ Preparation of special polishing liquid

[0030] According to the volume ratio: 5% brightener, 5% abrasive, 10% vaseline, 20% mixed fat, 60% kerosene.

[0031] The preparation method of special polishing liquid, the specific steps are as follows:

[0032] ① Ad...

example 2

[0037] Comparison experiment of grinding and polishing effect

[0038] ⑴Implementation conditions

[0039] Experimental equipment: BDE-1B frequency conversion and speed regulation optical two-axis grinding and polishing machine, Beijing Times surface roughness measuring instrument TR300, image acquisition microscope + Panasonic WV-CP460, S-3400NⅡ scanning electron microscope;

[0040] Polishing conditions: ambient temperature is room temperature, special diamond polishing liquid, diamond composite sheet workpiece, special silk polishing pad;

[0041] The polishing parameters are: the speed of the polishing disc is 80-180r / min, and the polishing pressure is 0.4-0.7KN / cm 2 , the polishing eccentricity is 35mm, the frequency is 16-20Hz, and the polishing time is 40-60min.

[0042] ⑵ Preparation of commonly used polishing liquid

[0043] The preparation ratio of the grinding liquid is: after the diamond abrasive with a particle size of W1 (the diameter of the abrasive grain is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com