Shell surface polishing equipment for appliance processing

A shell surface and equipment technology, applied in metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of dust generated by equipment, environmental pollution, and affecting the health of staff, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

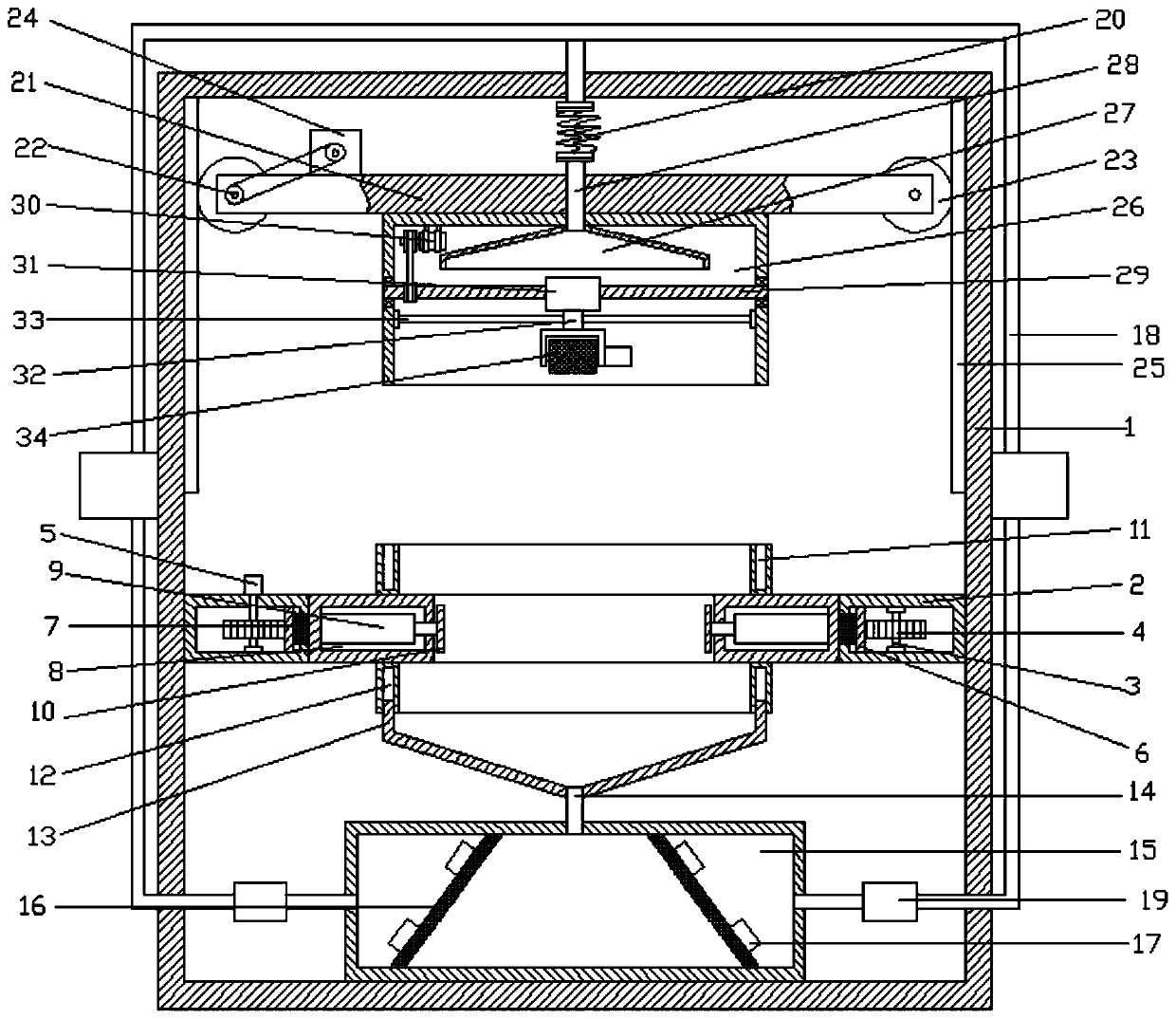

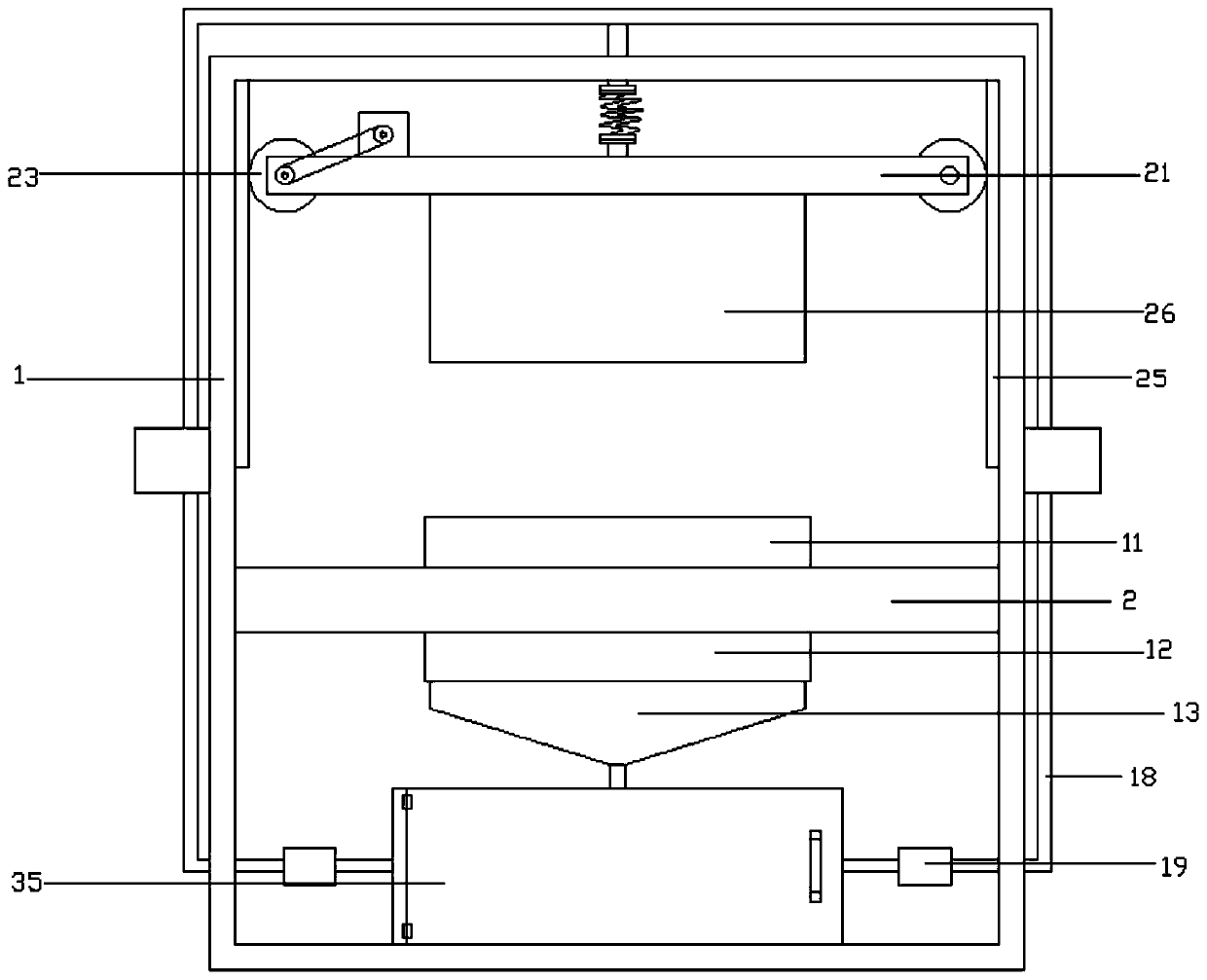

Embodiment 1

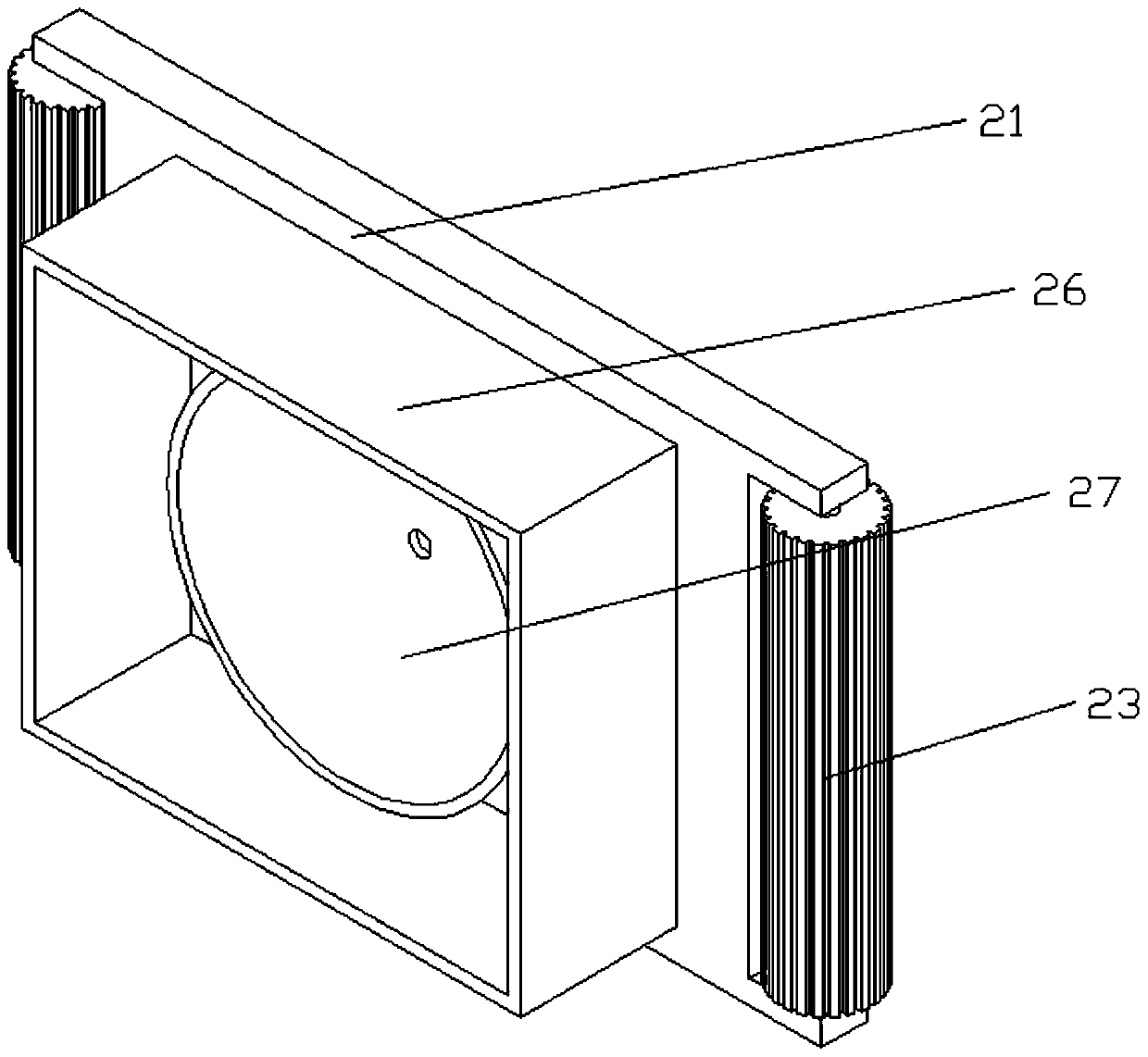

[0023] refer to Figure 1~3 , in an embodiment of the present invention, a shell surface polishing device for electrical processing, including a connecting frame 1, a connecting groove 2 is fixedly installed inside the connecting frame 1, and the connecting groove 2 is connected with a connecting gear 4 through a connecting shaft 3, A first motor 5 is installed on the upper side of the connecting shaft 3 at the left end, and the first motor 5 is installed on the upper side of the connecting groove 2. The inner side of the connecting gear 4 is meshed with an external gear 6, and the external gear 6 is connected with the mounting ring 7 through the connecting ring 7. The seat 8 is connected, the left and right ends of the mounting seat 8 are provided with telescopic rods 9, the inner side of the telescopic rod 9 is installed with an extrusion plate 10, and the extrusion plate 10 is arranged inside the groove inside the mounting seat 8, driven by the first motor 5 The connecting ...

Embodiment 2

[0027] The difference from Embodiment 1 is that a limiting rod 33 is arranged inside the connecting block 32, and the limiting rod 33 is fixedly connected with the connecting cover 26. Move on, can guarantee the stable movement of slide block 31 and connecting block 32 like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com