Double-side bottle blowing equipment

A technology of equipment and bottle body, which is applied in the field of double-side blowing equipment, can solve problems such as leakage of partitions and poor sealing, and achieve the effect of convenient blow molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

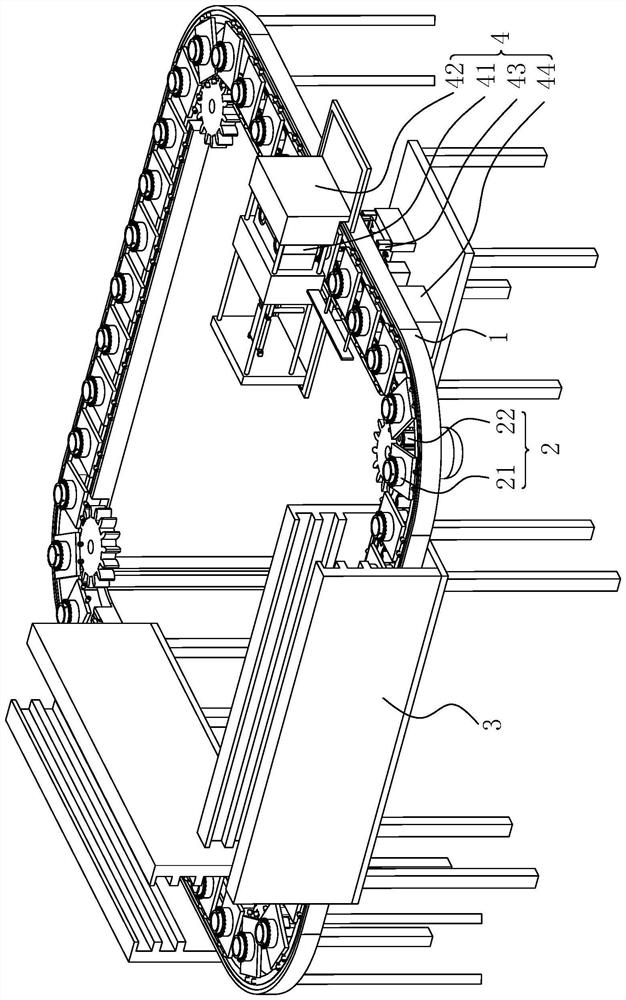

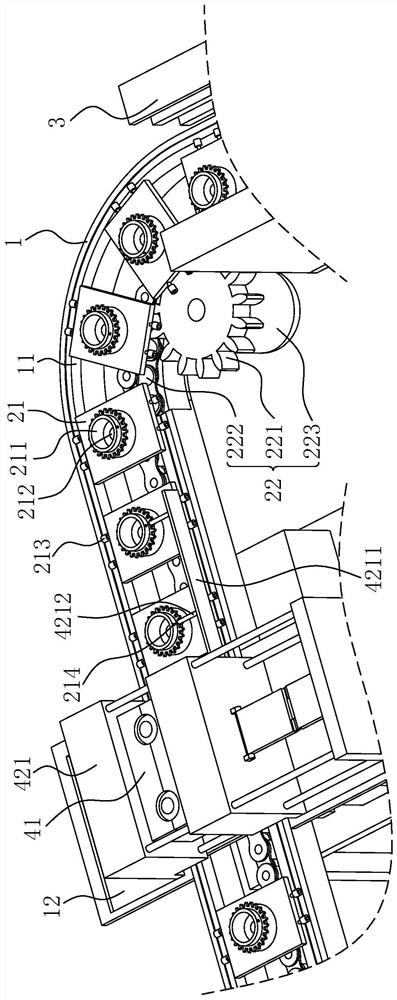

[0037] The following is attached Figure 1-6 The application is described in further detail.

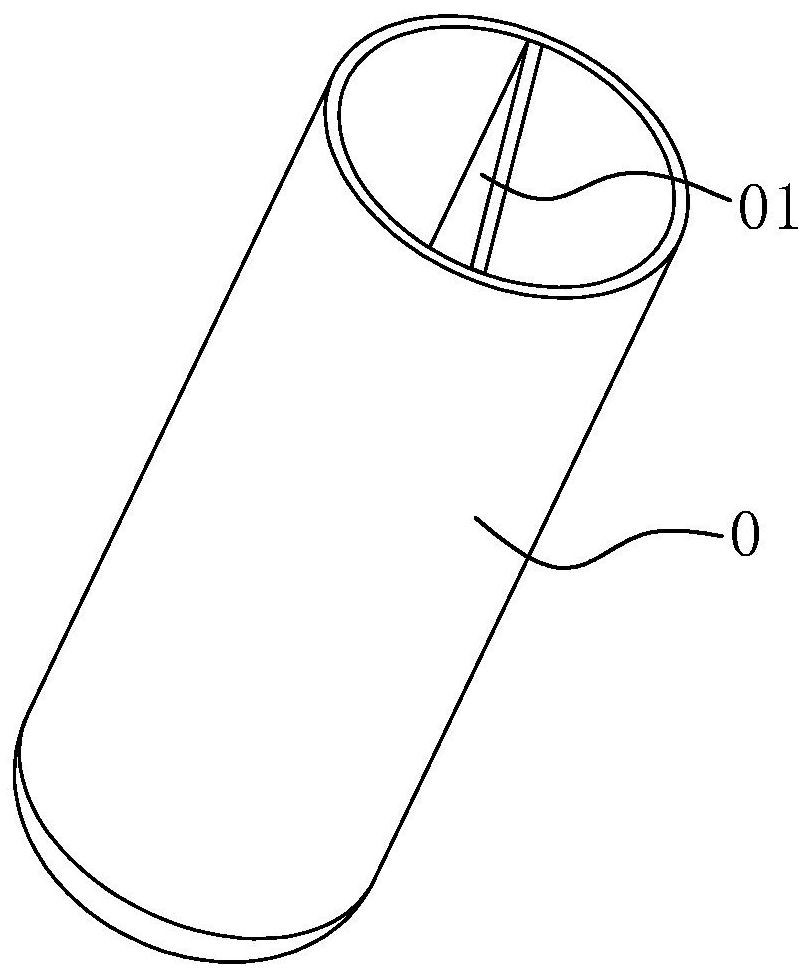

[0038] The embodiment of the present application discloses a double-sided bottle blowing device. refer to figure 1 and figure 2 , a double-sided bottle blowing equipment, which is used for blow molding both sides of the inner partition 01 of the bottle body 0 at the same time. The conveying device 2 includes several conveying seats 21 and a conveying part 22 for conveying the conveying seats 21 to the molding device 4 one by one. The preform on the conveying seat 21 is preheated, and the forming device 4 includes two molds 41 arranged on both sides of the conveying seat 21 in the conveying direction, a driving assembly 42 for driving the two molds 41 to approach or move away from each other, and a drive assembly 42 located on the conveying seat 21. The high-pressure blowing assembly 43 below and the cooling assembly 44 used to cool down the blow-molded bottle blank.

[0039] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com