Two-dimensional ultrasonic vibration polishing device for optical curved surface machining

A two-dimensional ultrasonic vibration and curved surface processing technology, which is applied to optical surface grinders, grinding drive devices, metal processing equipment, etc., can solve problems such as difficulty in forming normal curved surface radians, difficulty in angle adjustment, and reduction of ultrasonic polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

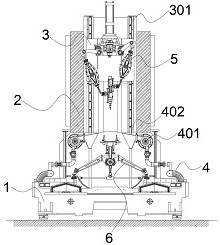

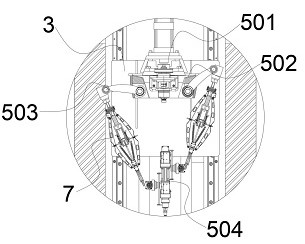

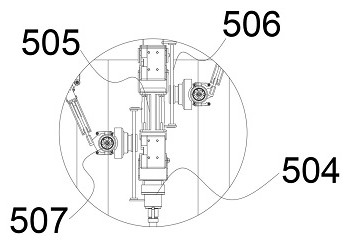

[0043] see figure 1 , in an embodiment of the present invention, a two-dimensional ultrasonic vibration polishing device for optical curved surface processing, which includes:

[0044] Processing base 1;

[0045] The main frame 2 is connected to the top, and is vertically fixed on the upper end surface of the processing base 1;

[0046] The offset clamping assembly 6 is arranged in the middle of the upper end surface of the processing base 1, and the offset clamping assembly 6 is used for positioning and clamping the workpiece to be processed, and at the same time, can adjust the track of the processed workpiece;

[0047] The fixed guide rail 301 is erected vertically and symmetrically on both sides of the upper connecting main frame 2;

[0048] The bearing seat 3 is set on the fixed guide rail 301 in a relatively slidable limit, and is driven to slide vertically by the transmission chain plate set in the upper connecting main frame 2;

[0049] The curved surface adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com