Assembly tooling and assembly method of piston cooling nozzle assembly

A technology for assembling piston cooling nozzles and assemblies, which is used in manufacturing tools, hand-held tools, etc., can solve the problems that the tooling cannot be assembled in place at one time, and the tooling size is large, so as to achieve less assembly space, convenient operation and good assembly process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments.

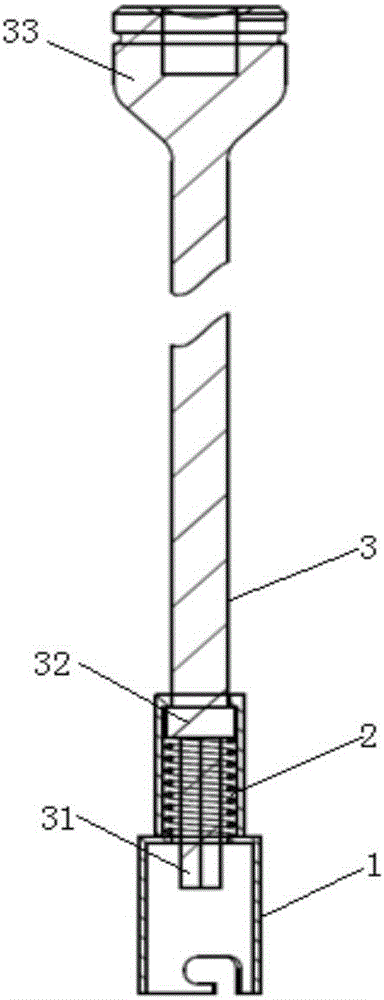

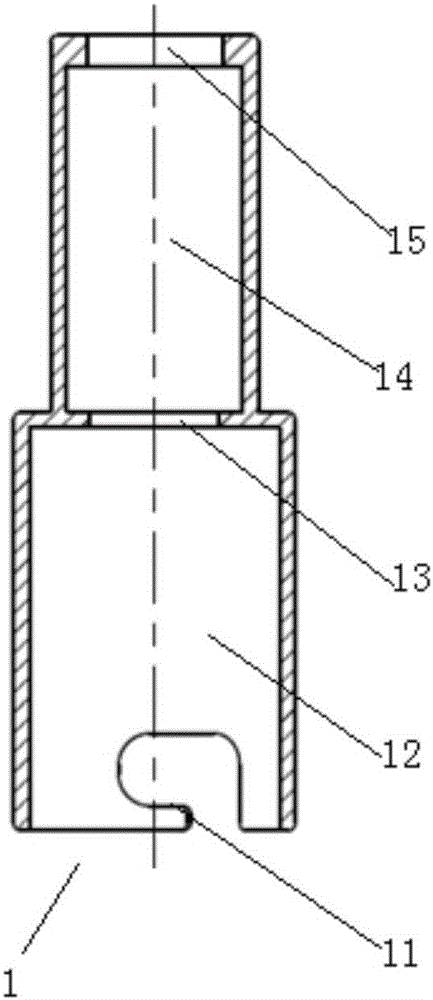

[0032] A piston cooling nozzle assembly assembly tool, such as Figure 1 to Figure 5 As shown, it includes a post 3, the upper end of the post 3 is a torsion joint 33, and the lower end of the post 3 is a hexagonal column 31 that matches the hexagonal hole of the spool bolt 42 of the piston cooling nozzle assembly 4, The hexagonal column 31 is sleeved with a hollow sleeve 1 whose lower end surface is an open structure. The hollow sleeve 1 is provided with a baffle plate 13 , and the upper end panel 15 of the hollow sleeve 1 and the baffle plate 13 are provided with and connected to each other. The center hole for the clearance fit of the rod 3, the upper end of the hexagonal column 31 is provided with a connecting rod pressure block 32 that restricts the hexagonal column 31 from falling out of the hollow sleeve 1, the connecting rod pressure block 32 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com