Milling machine fixing tool for intelligent carbon contact strip milling and using method of tool

A technology for fixing tooling and carbon slides, which is applied in positioning devices, milling machine equipment, details of milling machine equipment, etc. to facilitate milling work, avoid changing milling surfaces, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

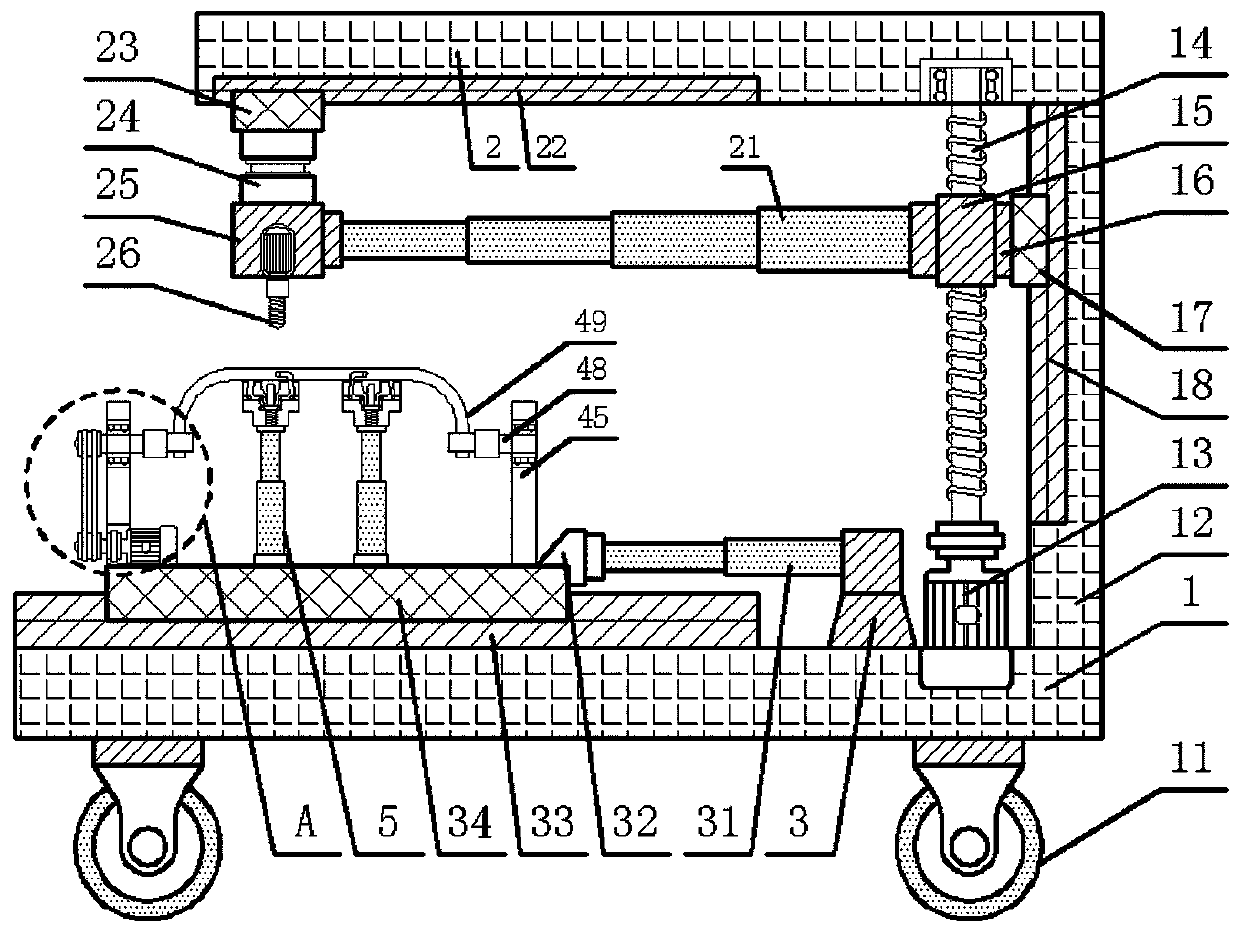

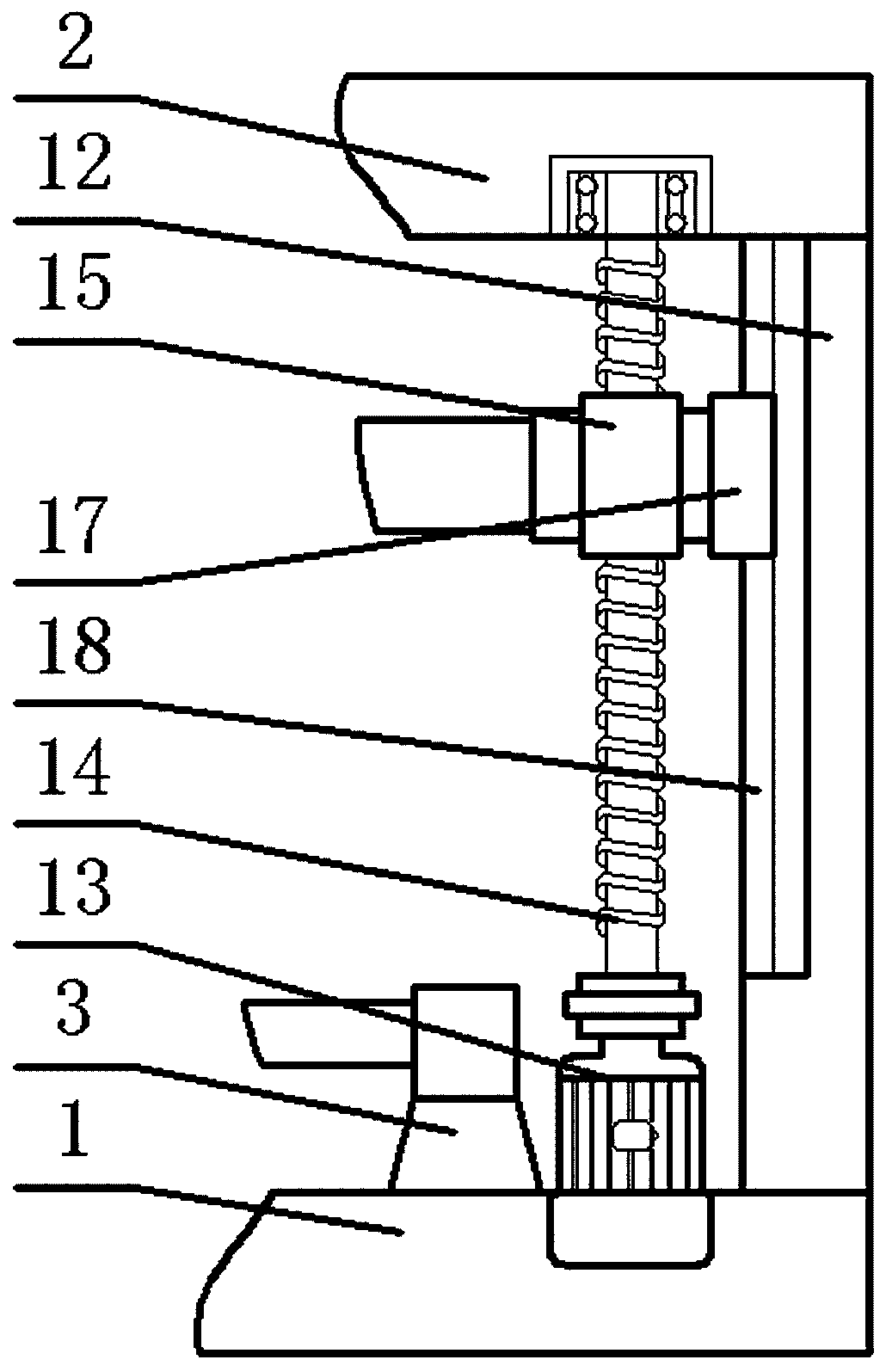

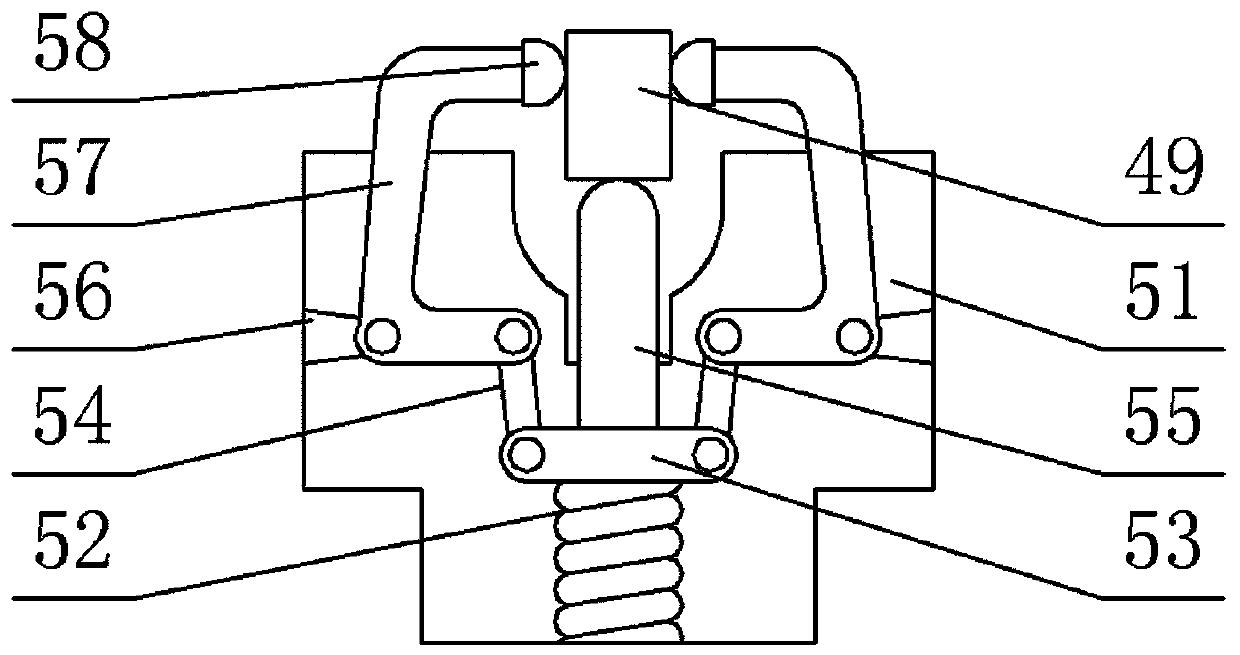

[0031] Embodiment 1: see Figure 1-4, a milling machine fixture for milling intelligent carbon skateboards, including a base plate 1 and a carbon slide plate 49, the base plate 1 is a rectangular plate placed horizontally and horizontally, and the carbon slide plate 49 is a bow-shaped long plate with the opening facing downwards, and the base plate 1 One side of the top surface is horizontally provided with a first slide rail 33, the first slide rail 33 is a T-shaped strip, and the middle part of the first slide rail 33 is provided with a rectangular plate-shaped first slide plate 34. The bottom surface of the slide rail 34 is horizontally recessed with a first chute in the shape of an inverted T, and the first slide rail 34 is slidingly engaged in the first chute; both sides of the top surface of the first slide plate 34 are longitudinally provided with a rectangular plate-shaped The baffle plate 45, the top of each baffle plate 45 is recessed with a through second bearing ho...

Embodiment 2

[0038] Example 2: see Figure 5 , in this embodiment, the present invention also proposes a method for using a milling machine fixed tool for intelligent carbon slide milling, including the following steps:

[0039] Step 1, control the first telescopic cylinder 31 to drive the first slide plate 34 to move laterally along the first slide rail 33, the worker inserts the two ends of the carbon slide plate 49 into the corresponding limit cylinders 46 respectively, and controls the movement of the third telescopic cylinder 5 The telescopic rod rises, and then drives the clamping mechanism to clamp the carbon slide 49;

[0040] Step 2, the bottom of the carbon slide 49 is horizontally clamped in the limit groove, and the top of the limit rod 55 is pressed down by force, and then the support block 53 is driven down and the support spring 52 is compressed, and at the same time, the clamping rod is driven by the hinged connecting rod 54 57, so that the fixed block 58 at the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com