A grinding and mixing device for ceramic powder raw materials

A technology of ceramic powder and mixing device, which is applied to clay preparation devices, clay mixing devices, chemical instruments and methods, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of reducing trouble, improving labor efficiency, and efficiently grinding and pulverizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

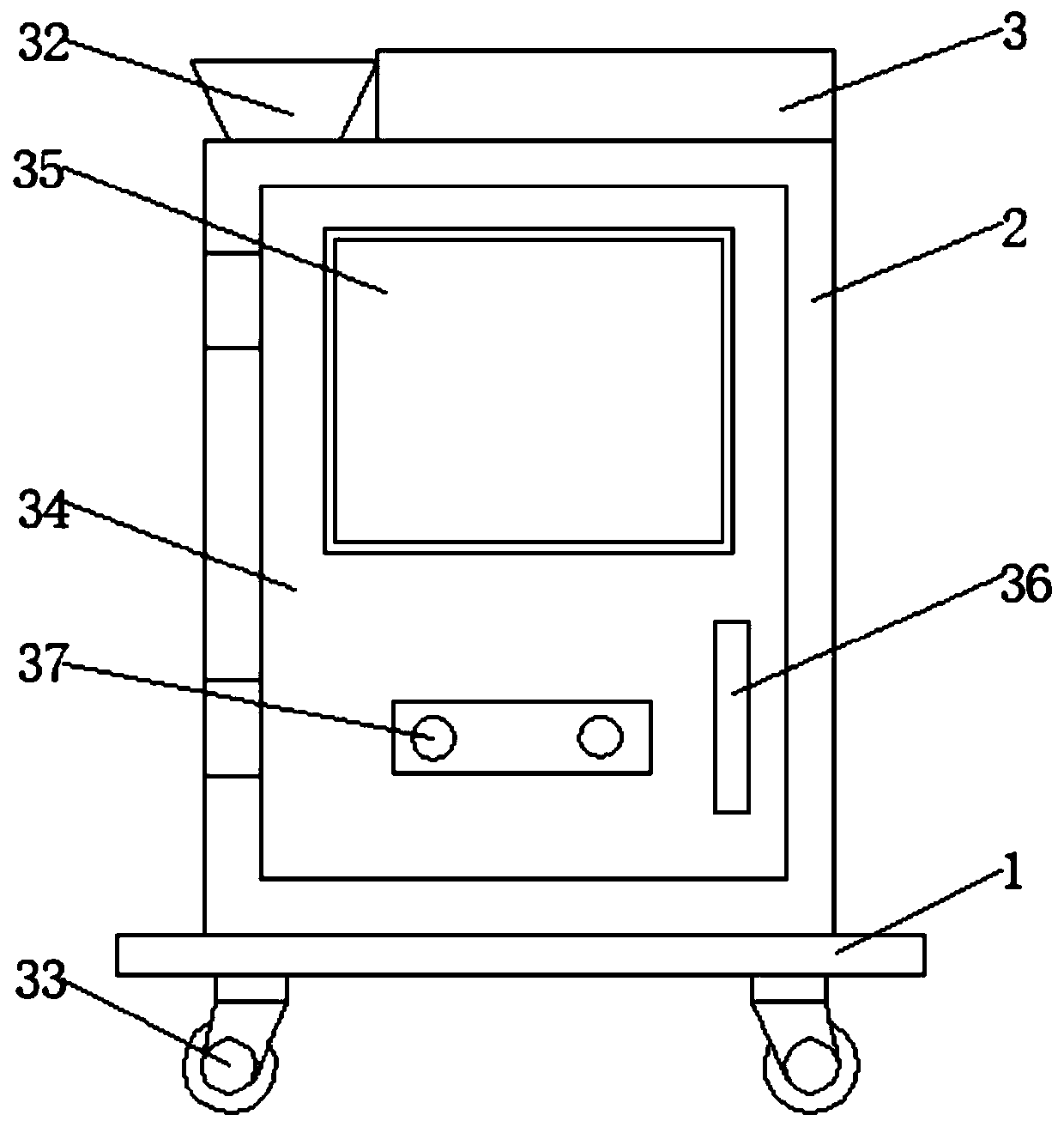

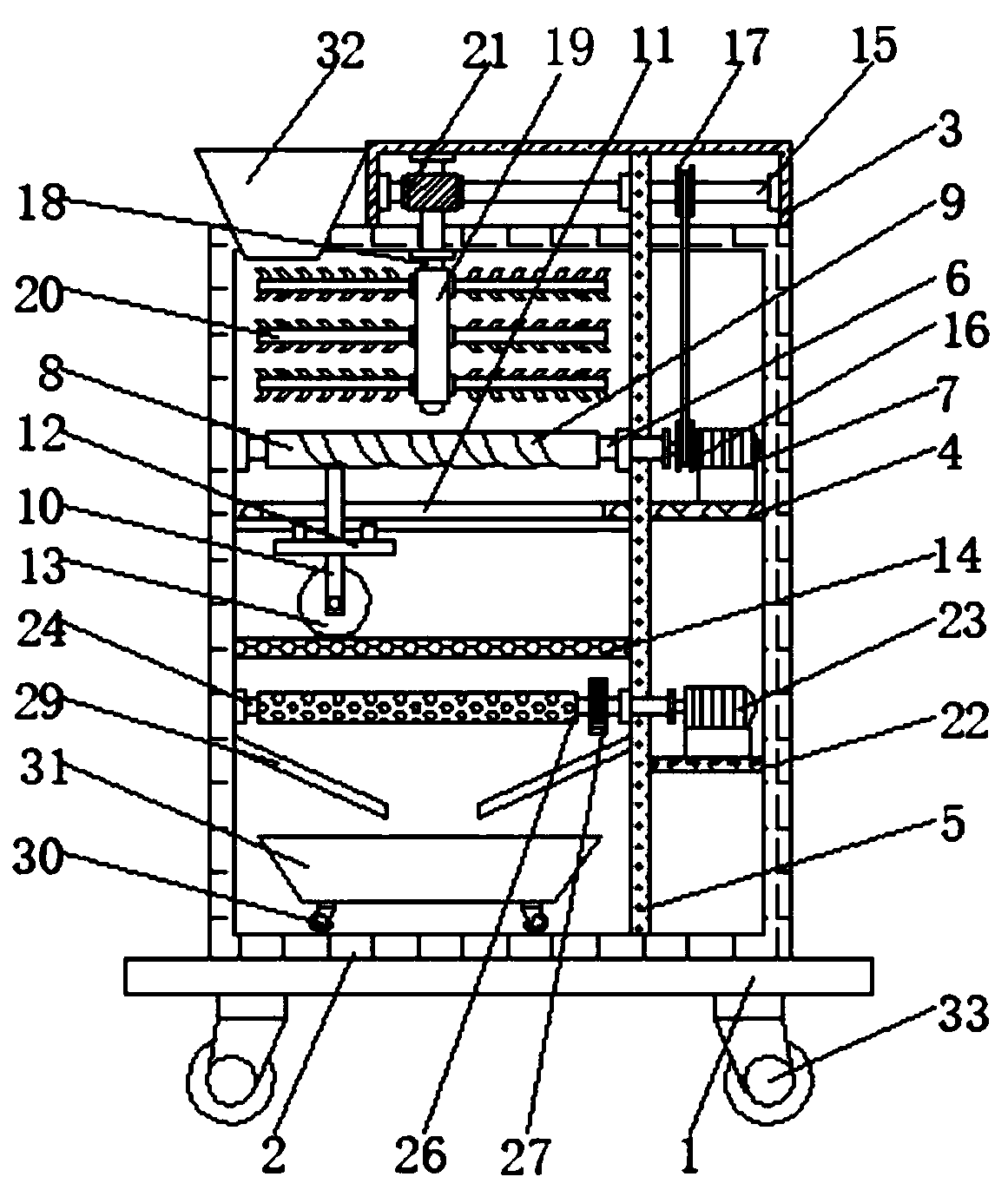

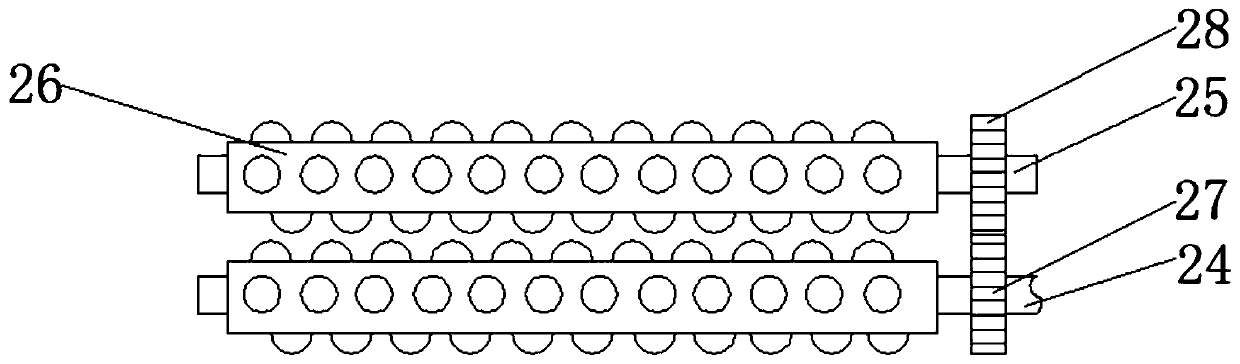

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the present invention provides a technical solution: a ceramic powder raw material grinding and mixing device, including a bottom plate, the top of the bottom plate 1 is fixedly connected with a box body 2, and one side of the top of the box body 2 is fixedly connected with a protective cover 3, One side of the inner wall of the box body 2 and one side of the riser 5 and the bottom of the partition 4 are fixedly connected with a slide rail, and the bottom of the slide rail is fixedly connected with a mounting plate 12, and the top of the mounting plate 12 passes through the slider and the slide rail Slidingly connected to the bottom of the partition 4, the bottom end of the rectangular rod 10 runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com