Shock-absorption sneaker sole

A technology for sports and insoles, applied in soles, footwear, applications, etc., can solve problems such as inability to cushion and assist the soles of the feet, limited elasticity of elastic shoe materials, and inability of elastic shoe materials to effectively cushion and assist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

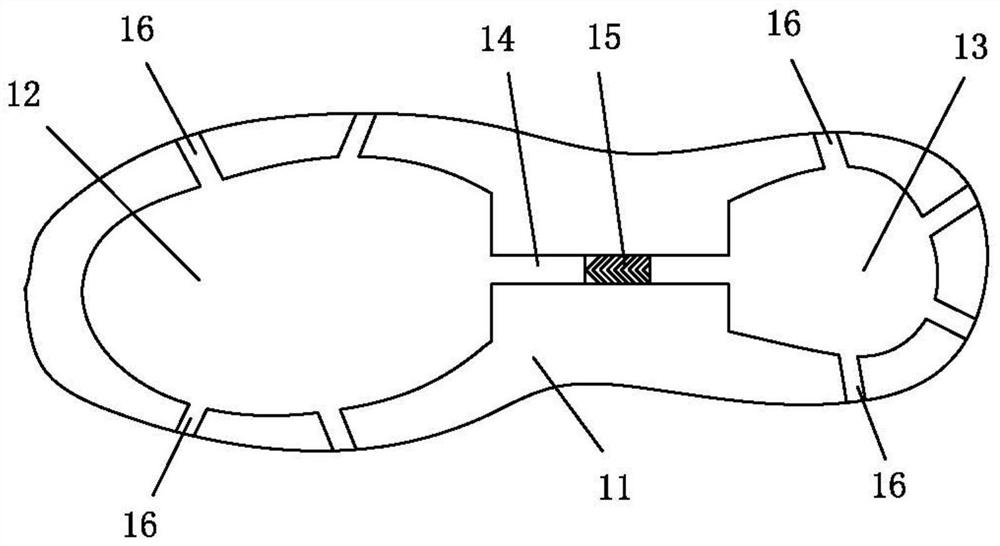

[0030] like figure 1 As shown, a shock-absorbing sports shoe sole includes a bottom assembly, a midsole body and an insole that are sequentially compounded from bottom to top, the bottom assembly includes a bottom body and an airbag assembly, and the bottom body is provided with a Place the accommodation groove of the airbag assembly, the airbag assembly includes a front airbag corresponding to the forefoot of the human body, a rear airbag corresponding to the heel of the human body, and a connecting pipe connecting the front airbag and the rear airbag, and the outer peripheries of the front airbag and the rear airbag are all arranged There are several ventilation pipes communicating with the outside air, and a one-way valve for controlling the movement of the gas in the rear air bag to the front air bag is arranged in the communication pipe.

[0031] First of all, the present invention sets a front airbag and a rear airbag respectively at positions corresponding to the forefo...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

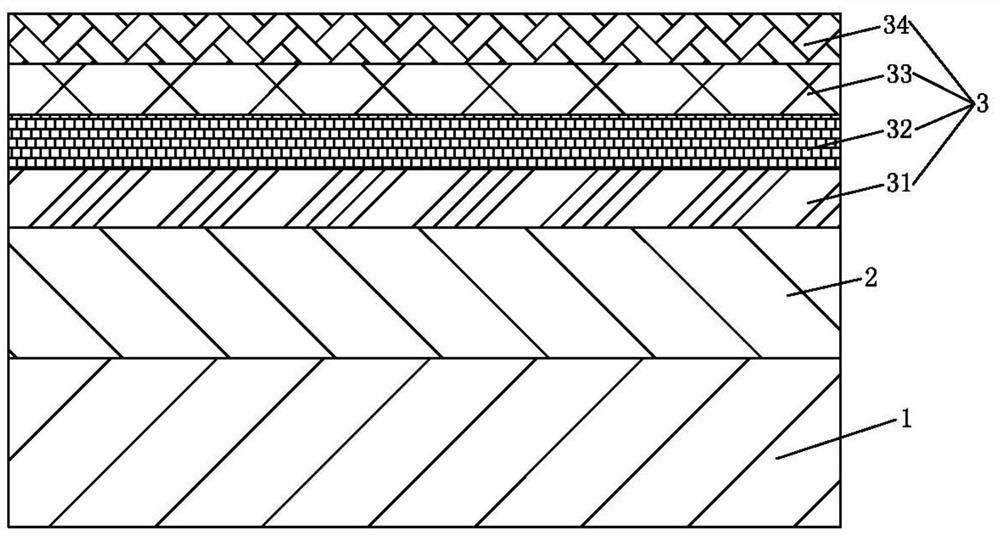

[0037] like figure 2 As shown, wherein, the insole comprises a first viscose layer, a bamboo charcoal non-woven fabric layer, a second viscose layer and a cotton cloth layer compounded sequentially from bottom to top, and the first viscose layer is far away from the bamboo charcoal non-woven fabric layer One side is bonded to the midsole. Bamboo charcoal can inhibit the reproduction of fungi, absorb moisture and deodorize, and also has a certain infrared emission function, which can meet people's requirements for shoes comfort, health, environmental protection and health care.

[0038] Wherein, the first adhesive layer is a TPU hot-melt adhesive layer, which has good cohesiveness, can firmly bond the insole and the midsole together, and is not easy to delaminate.

[0039] Wherein, the bamboo charcoal nonwoven fabric layer comprises two layers of nonwoven fabric layers and a bamboo charcoal powder layer com...

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is:

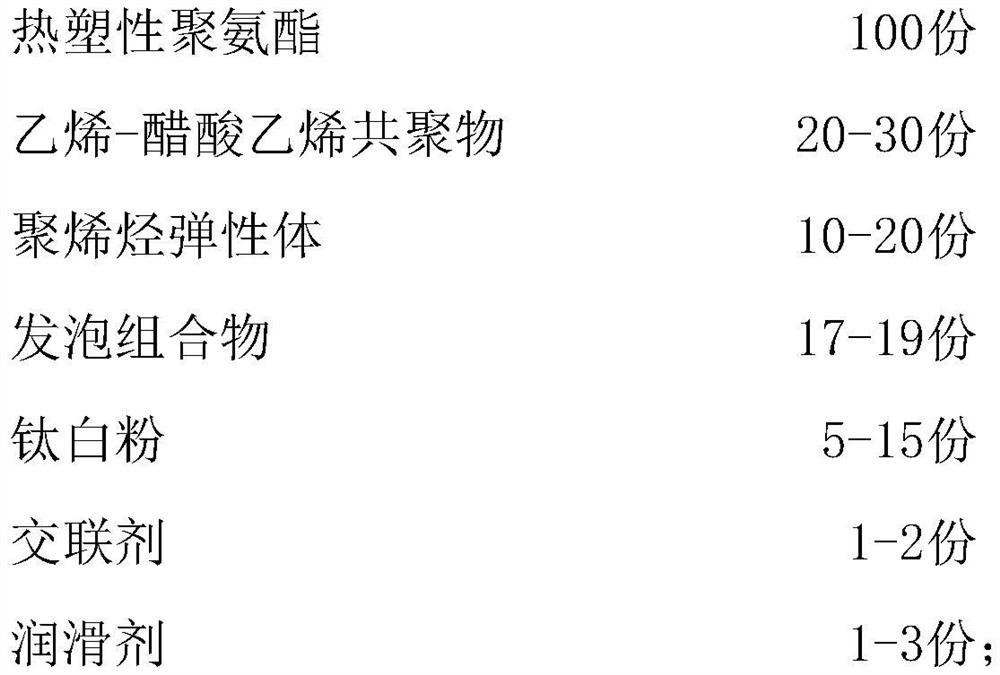

[0043] Wherein, the TPU foam sole is made by foaming a TPU foam material, and the TPU foam material is composed of the following raw materials in parts by weight:

[0044]

[0045] The foam composition is prepared through the following steps: A, mixing 10 parts by weight of carboxylated styrene-butadiene rubber latex and 0.15 parts by weight of irradiation agent, and then carrying out ultraviolet irradiation treatment; B, after ultraviolet irradiation treatment, Add 1.5 parts by weight of azodicarbonamide into the carboxylated styrene-butadiene latex, perform ultrasonic dispersion, and vacuum spray dry to obtain the foaming composition.

[0046] Wherein, the thermoplastic polyurethane is German BASF E68, the ethylene-vinyl acetate copolymer is EVA3178, and the polyolefin elastomer is Dow POE8480.

[0047] Wherein, in the step A, the carboxylated styrene-butadiene latex is BASF SD516, the UV radiation dose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com