Measurement device and measurement method of exhaust area of single-guide vane

A technology of exhaust area and guide vanes, applied in the field of aero-engine inspection, can solve the problems of low assembly efficiency and long assembly cycle of guide vanes, and achieve the effect of shortening assembly and measurement cycle, improving efficiency and shortening production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

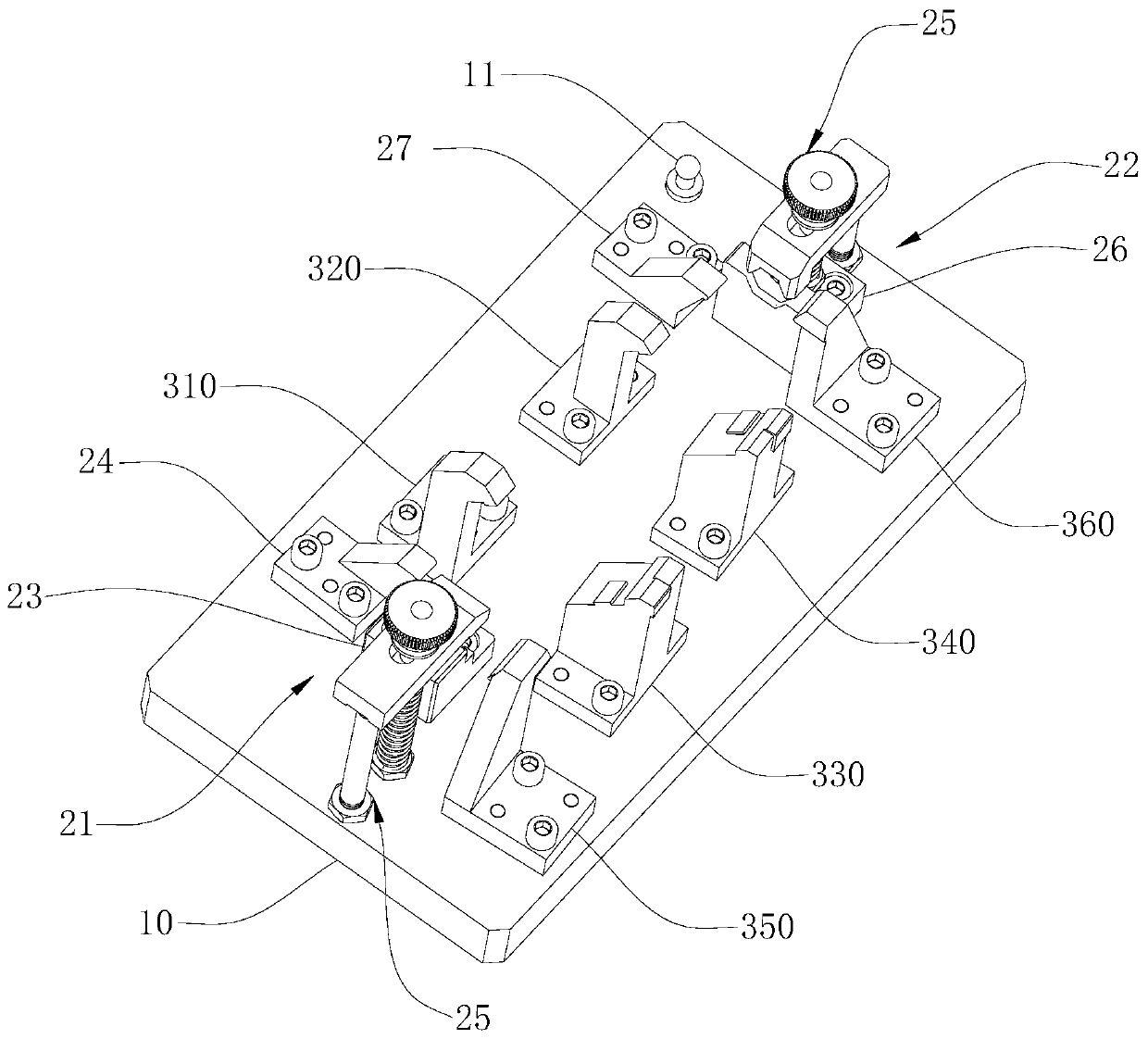

[0051] Please refer to figure 1 , a device for measuring the exhaust area of a single guide vane, comprising: a base 10, a fixing device and a simulation device, the fixing device and the simulation device are installed on the top of the base 10 respectively. A ball stud 11 is also provided on the base 10 .

[0052] The fixing device includes a first positioning assembly 21 and a second positioning assembly 22, the first positioning assembly 21 and the second positioning assembly 22 are respectively used to fix one end of the blade 400 to be tested with a large edge plate and one end with a small edge plate, Thereby simulating the position of the blade 400 to be tested in the casing of the guider.

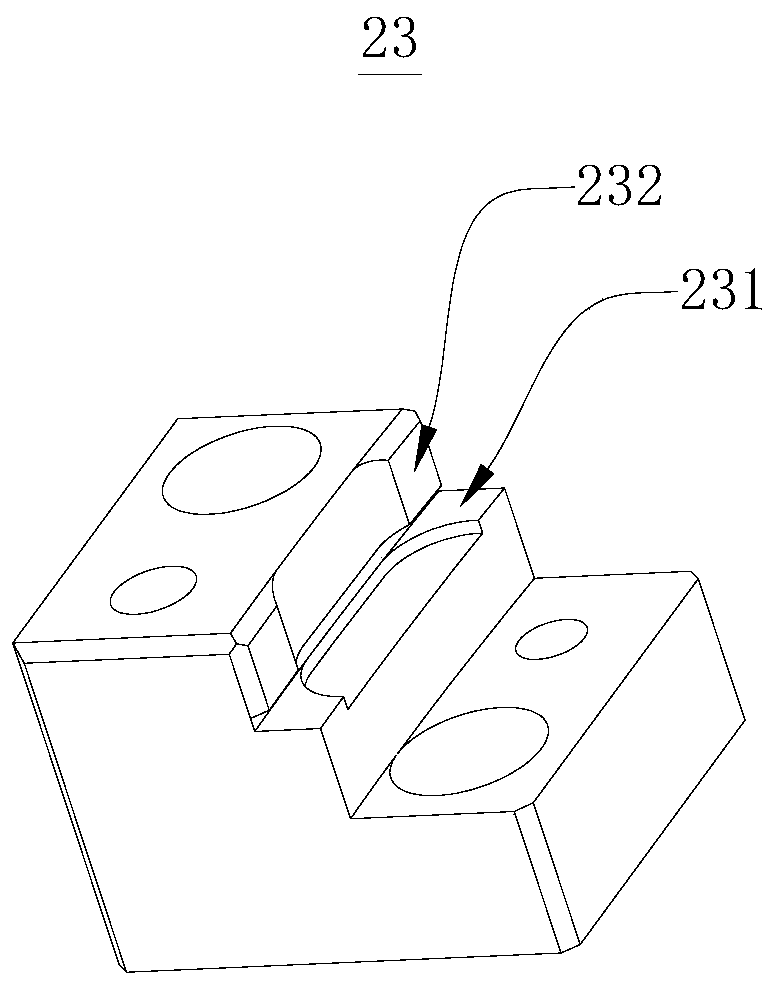

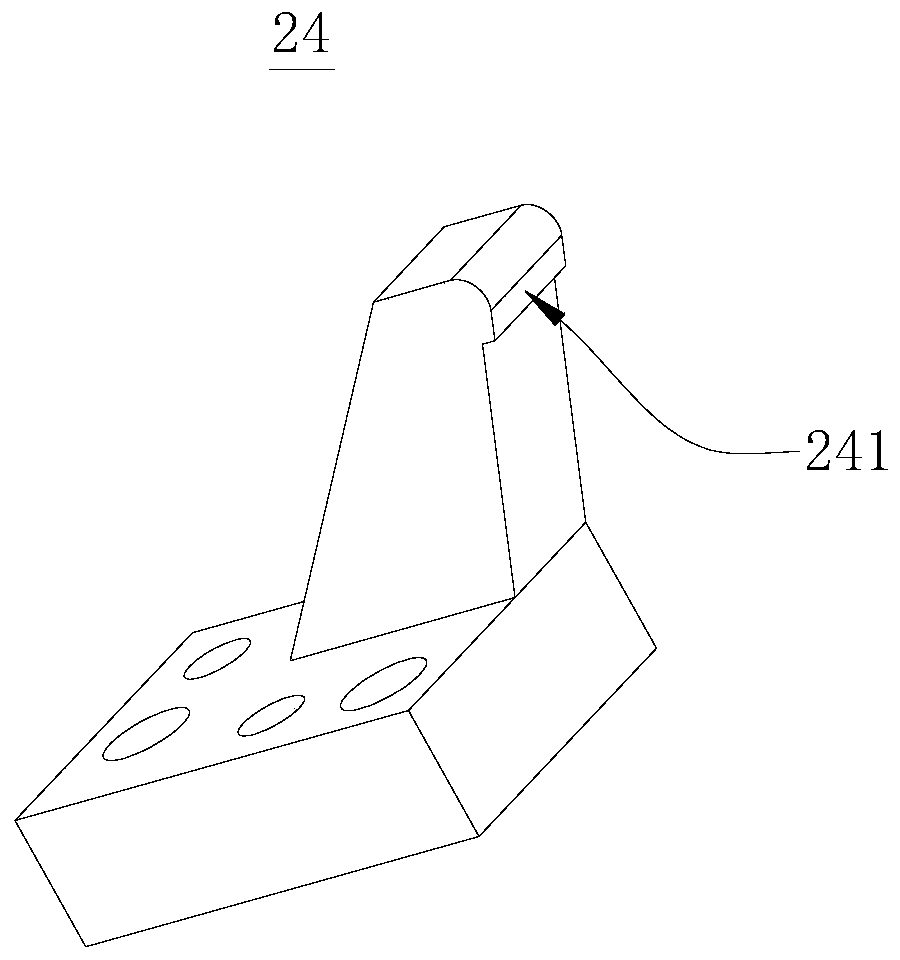

[0053] The simulation device comprises a first dorsal blade simulation block 310, a second dorsal blade simulation block 320, a first pot side blade simulation block 330, a second pot side blade simulation block 340, a large edge plate simulation block 350 and a small edge plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com