Blanking extrusion die for soldering lug

A stamping die and blanking technology, applied in the field of blanking stamping die, can solve the problems of waste of raw materials, low stamping efficiency of the die, high production cost, etc., and achieve the effect of avoiding repeated replacement, simple operation, and improving the utilization rate and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

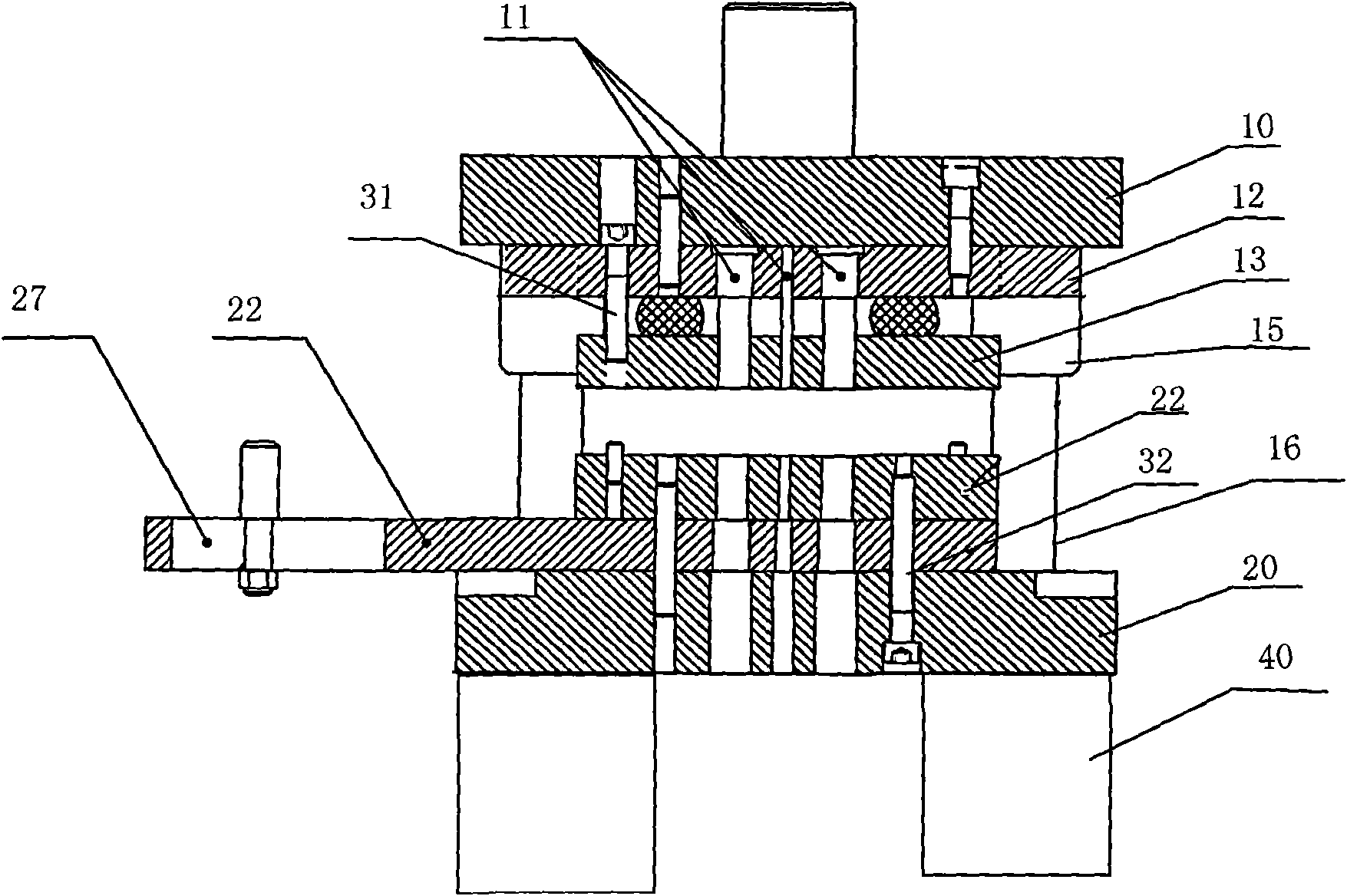

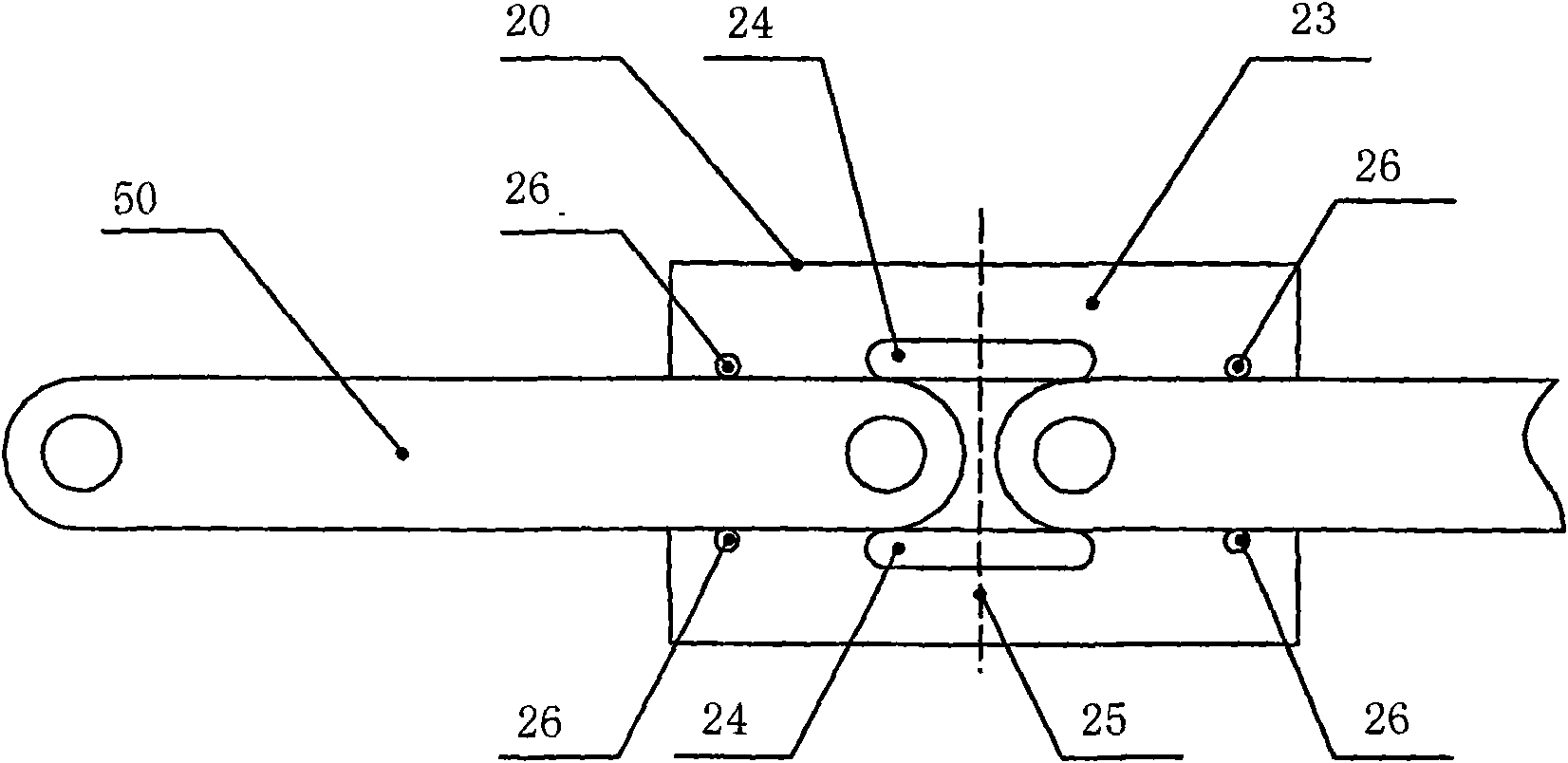

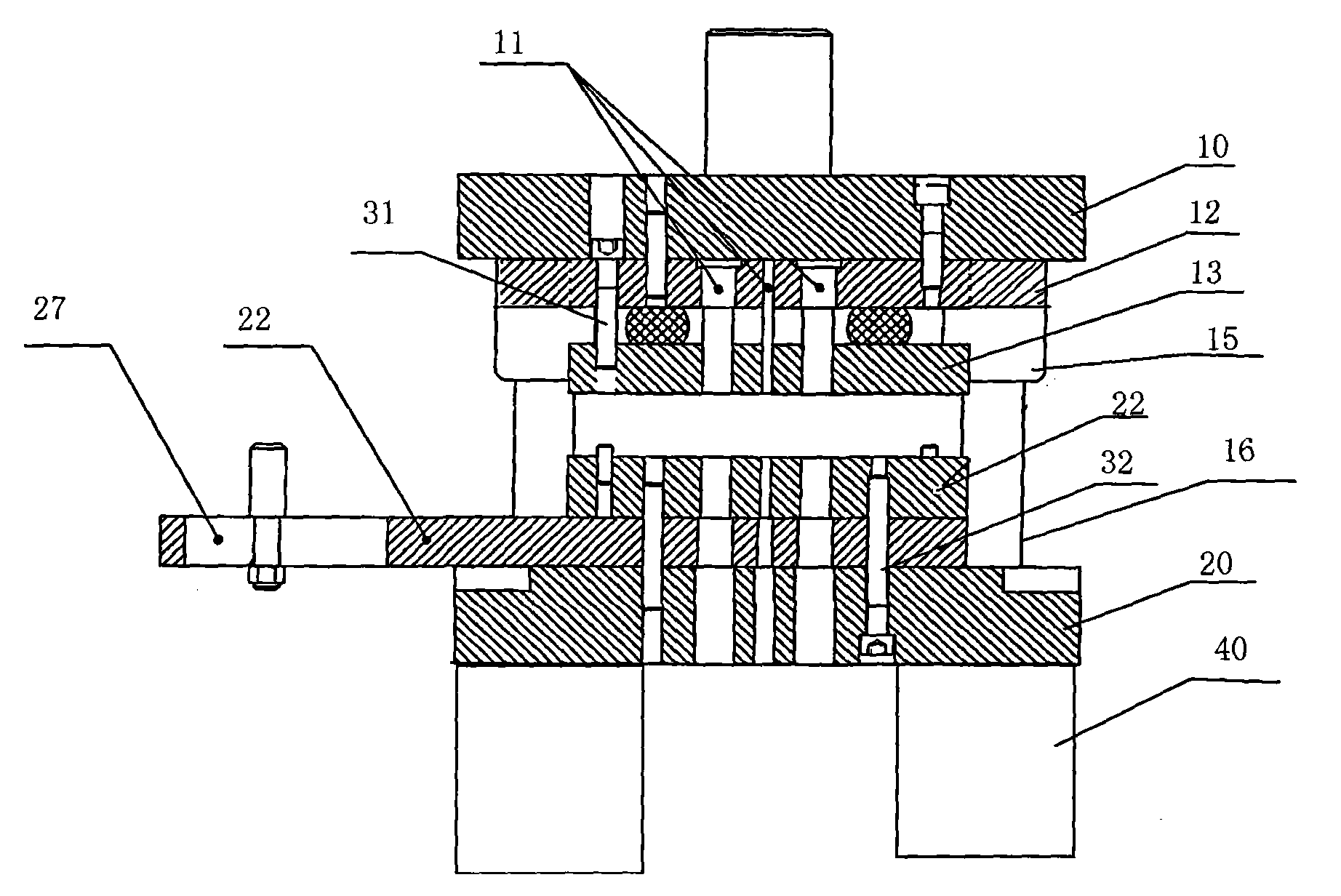

[0015] see figure 1 , the solder tab blanking stamping die of the present invention includes an upper die base 100, an upper backing plate 12, a punch 11 on the upper die base 10, a lower die base 20, a lower backing plate 22, a die 21 and a stripper plate 13; A mold foot 40 that increases the stability of mold processing is installed at the bottom of the lower mold base 20, which is convenient for users to use.

[0016] The first guide punch 31 pierced between the above-mentioned upper die base 10, the upper backing plate 12 and the stripper plate 13, the above-mentioned structure is the same as that of the existing single-branch terminal stamping die, and on the basis of the above-mentioned structure, the following Between the mold base 20, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com