Algae-bacterium gel dressing and preparation method thereof

A technology of gel and gel particles, applied in bandages, absorbent pads, medical science, etc., can solve problems such as waste, wound dressings cannot deliver therapeutic substances for a long time, and chronic inflammation is difficult to heal, so as to achieve large hydrogen production and produce Hydrogen time is long, the effect of promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

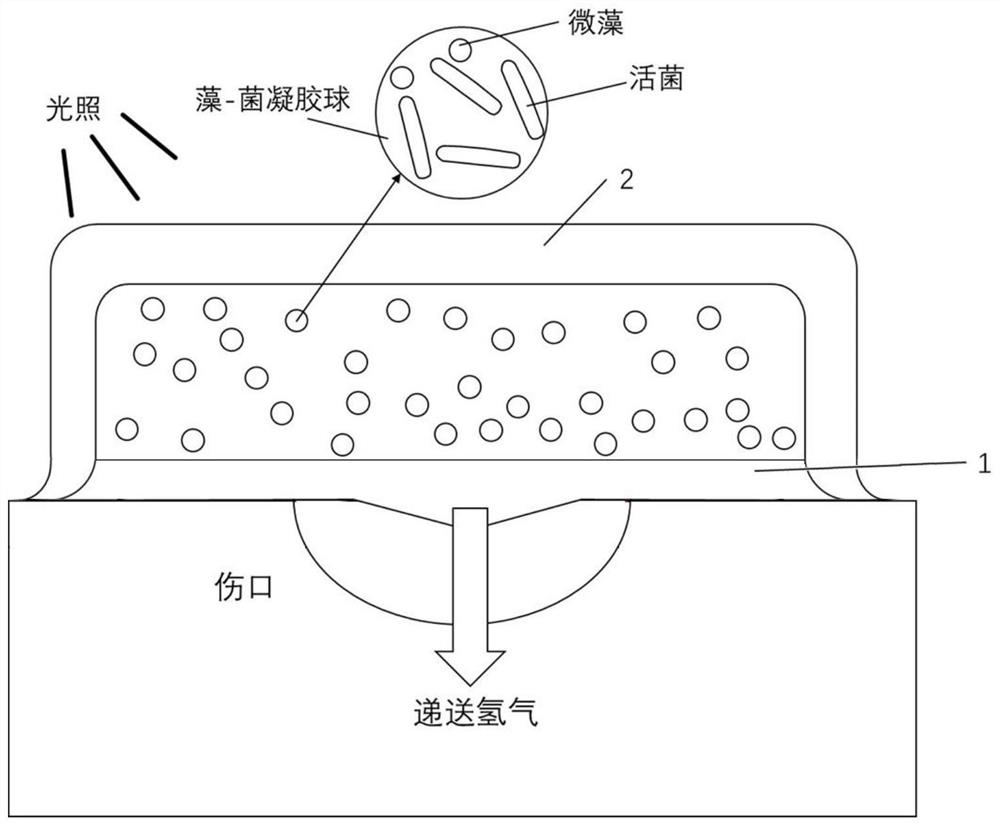

[0046] (1) Preparation of algae-bacteria gel dressing:

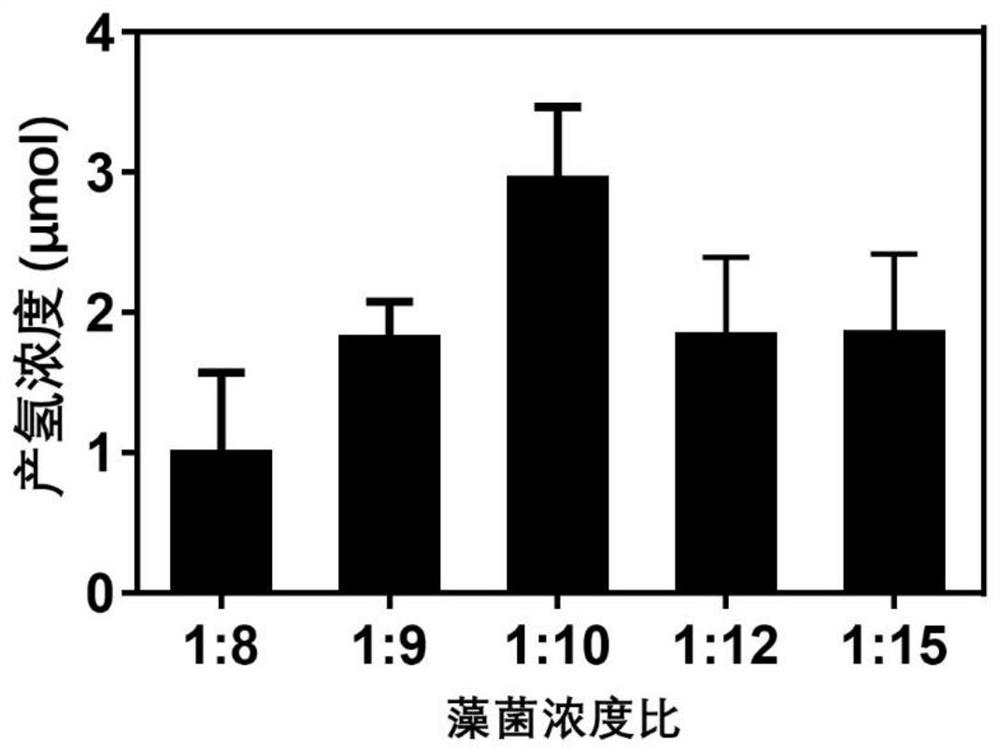

[0047] Mix Chlorella, live Bacillus licheniformis and sodium alginate aqueous solution (mass concentration: 1%~4%), wherein the volume of the mixture of Chlorella, Bacillus licheniformis and sodium alginate solution is 1:1 ~1:2 between. The mixture was then injected into a 3% (w / v) calcium chloride solution to prepare a gel. In the obtained gel, the concentration of the total number of microorganisms (the concentration of the total number of algae and bacteria) was 1.4×10 8 ~8×10 8 individual / mL.

[0048] The obtained gel is transferred to a hydrophilic PTFE polytetrafluoroethylene film with a pore size of 0.1-0.22um, and a transparent and airtight waterproof polyurethane adhesive film is pasted on the gel to obtain a molded dressing.

[0049] The inner lining layer allows the gas and water to permeate the tissue in one direction and efficiently, and at the same time isolates the transmembrane diffusion of microalgae...

Embodiment 2

[0057] Mix Scenedesmus obliquus, Phaeodactylum tricornutum, live Bacillus subtilis with Poloxamer solution (mass concentration 20%~30%). The ratio is 1:6, the mixed solution of Scenedesmus oblique, Phaeodactylum tricornutum and live Bacillus subtilis (the total concentration of microorganisms is 3.5×10 8 ~8×10 8 Individuals / mL) and the volume of poloxamer solution is between 1:1~1:2. Then the mixture was left to stand to obtain a gel.

[0058] The obtained gel is transferred to a hydrophilic PTFE polytetrafluoroethylene film with a pore size of 0.1-0.22um, and a transparent and airtight waterproof polyurethane adhesive film is pasted on the gel to obtain a molded dressing.

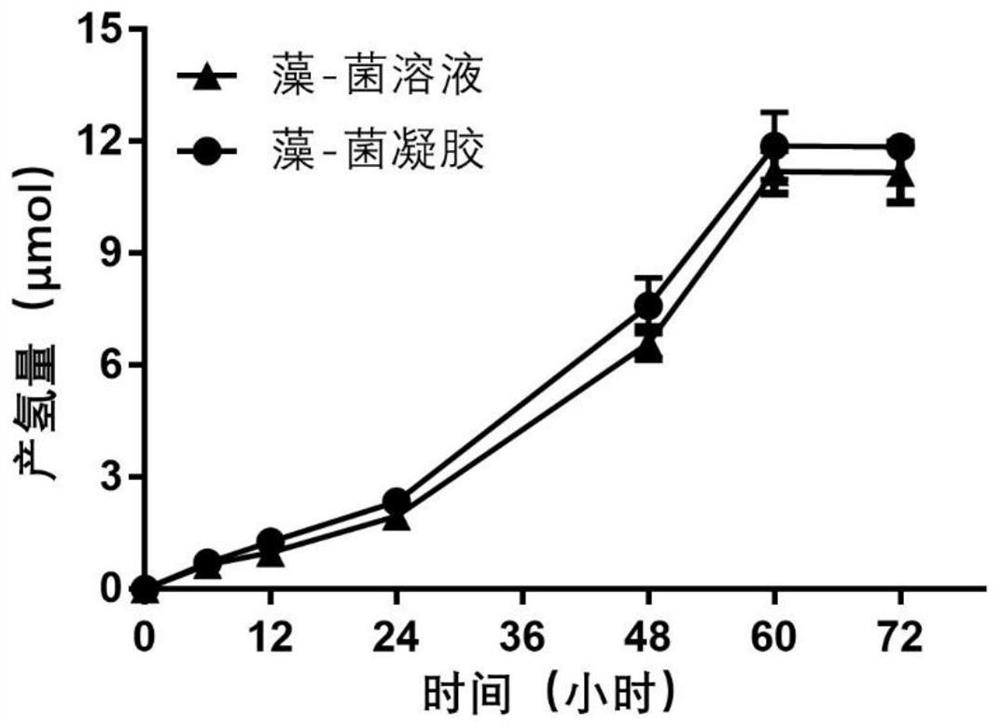

[0059] The obtained gel was tested by the method of step (2) in Example 1, and the hydrogen production concentration was 4.2 μmol.

Embodiment 3

[0061] Mix Synechococcus, Anabaena, live Rhodospirillum rubrum with 0.5%-1% photoinitiator, 2-methylpropiophenone, gelatin-methacrylamide solution (mass concentration is 10%~30% ) and mix well, wherein the number ratio of Synechococcus and Anabaena to Rhodospirillum rubrum is 1:8, Synechococcus, Anabaena, Rhodospirillum and photoinitiator, 2-methylpropane Mixture of ketones (in which the total concentration of microorganisms is 3.5×10 8 ~8×10 8 per mL) and gelatin-methacrylamide solution in a volume ratio of 1:1. Then the mixed solution is irradiated with 405nm light for 10-30s to make the mixed solution gel, and the gel is obtained after standing still.

[0062] The obtained gel is transferred to a hydrophilic PTFE polytetrafluoroethylene film with a pore size of 0.1-0.22um, and a transparent and airtight waterproof polyurethane adhesive film is pasted on the gel to obtain a molded dressing.

[0063] The obtained gel was tested by the method of step (2) in Example 1, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com