Anti-seismic H-type steel and production method thereof

A production method and technology for H-beam, applied in the direction of temperature control, etc., can solve the problems of reducing the welding performance and toughness of steel, and high production cost, and achieve the effect of improving seismic performance, good combination of strength and toughness, and excellent comprehensive seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

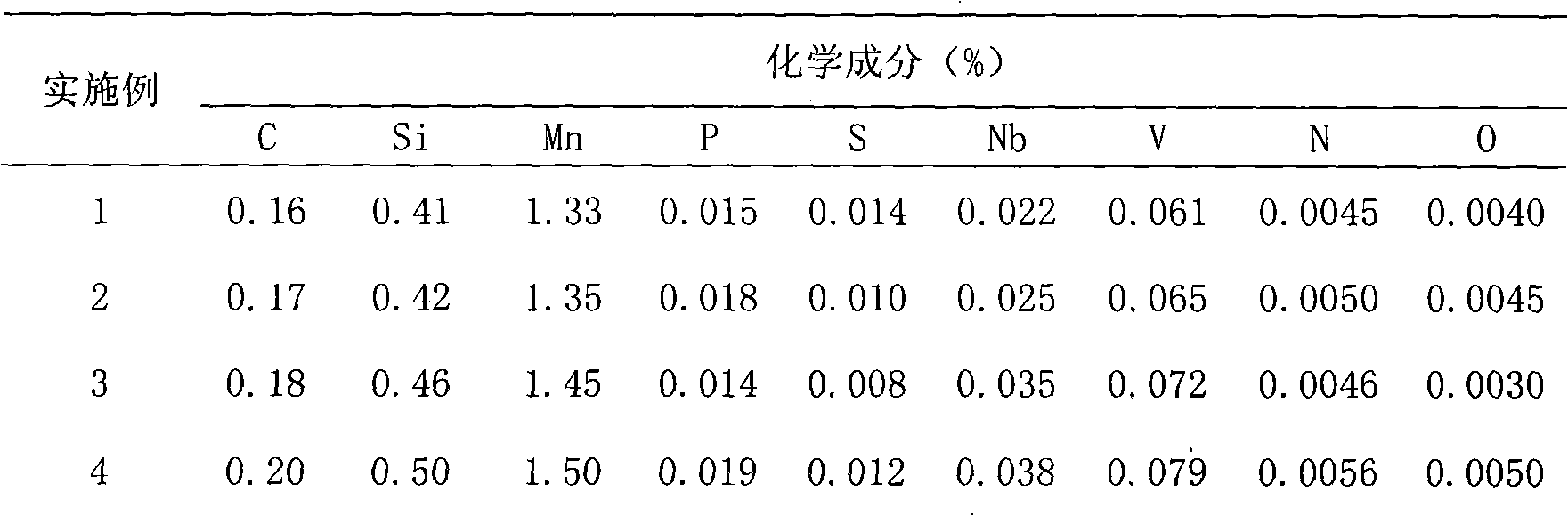

[0021] The chemical composition of the anti-seismic H-beam is shown in Table 1 Example 1. The rolling process parameters are: heating temperature 1210°C; deformation below 950°C 50%; final rolling temperature 850°C.

[0022] The performance index is: R eL 500MPa, R m is 665MPa, R eL / R m 0.75, A is 24%, ΔE is 2.08%, 0°C longitudinal KV is 74J, cycle toughness value σ a ·Δε t 34.07J / cm 3 . The above indicators are better than the five performance indicators of anti-seismic steel.

Embodiment 2

[0024] The chemical composition of the anti-seismic H-beam is shown in Table 1, Example 2. The rolling process parameters are: heating temperature 1220°C; deformation below 950°C 55%; final rolling temperature 880°C.

[0025] The performance index is: R eL is 480MPa, R m 650MPa, R eL / R m 0.74, A is 20.5%, ΔE is 3.2%, 0°C longitudinal KV is 115J, cycle toughness value σ a ·Δε t 37.82J / cm 3 . The above indicators are better than the five performance indicators of anti-seismic steel.

Embodiment 3

[0027]The chemical composition of the anti-seismic H-beam is shown in Table 1, Example 3. The rolling process parameters are: heating temperature 1230°C; deformation below 950°C 60%; final rolling temperature 820°C.

[0028] The performance index is: R eL 530MPa, R m 695MPa, R eL / R m 0.76, A is 20.5%, ΔE is 2.44%, 0°C longitudinal KV is 76J, cycle toughness value σ a ·Δε t 33.06J / cm 3 . The above indicators are better than the five performance indicators of anti-seismic steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com