Copolymer gel, 4D micro-nano printing material, and printing test method

A testing method and technology of copolymers, which are applied in the fields of biochemical equipment and methods, microbial determination/inspection, microorganisms, etc., can solve the problem of insufficient supporting force of active response hydrogel materials, poor stability of hydrogel swelling properties, complex three-dimensional structure and other problems, to achieve the effects of good photocuring performance, good swelling stability, and high swelling differentiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

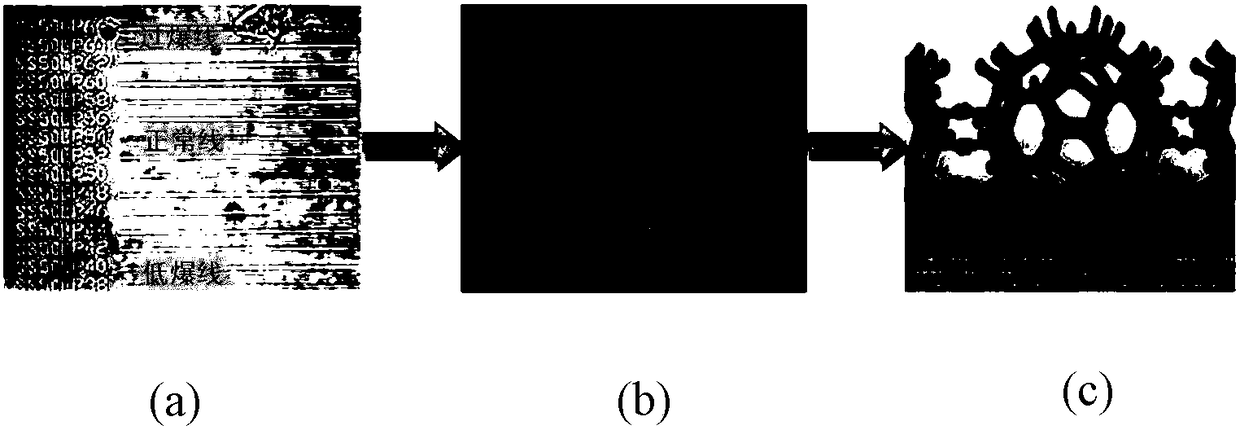

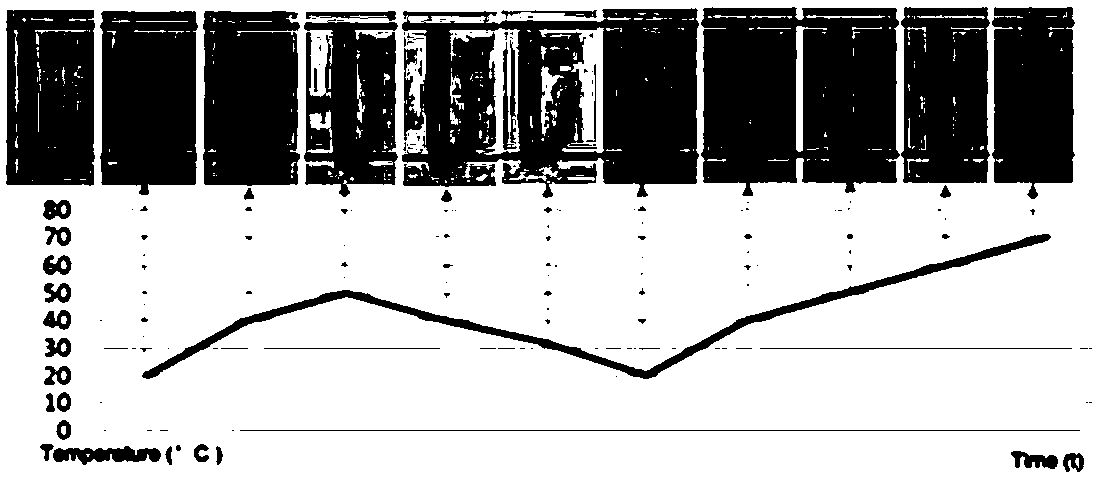

Image

Examples

preparation example Construction

[0059] The embodiment of the present invention also provides a preparation method of copolymer gel, comprising:

[0060] Add functional monomer N-isopropylacrylamide and acrylic acid to ethyl lactate solution and stir;

[0061] adding a viscosity modifier to obtain the first solvent;

[0062] The first solvent is mixed with a photosensitizer triethanolamine and a photoinitiator in 4,4'-bis(diethylamino)benzophenone solution, and stirred to obtain a hydrogel precursor.

[0063] For the addition amount and specific selection of each component, refer to the content described in the above copolymer gel example, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com