Light-solidified resin and dispersing agent using same

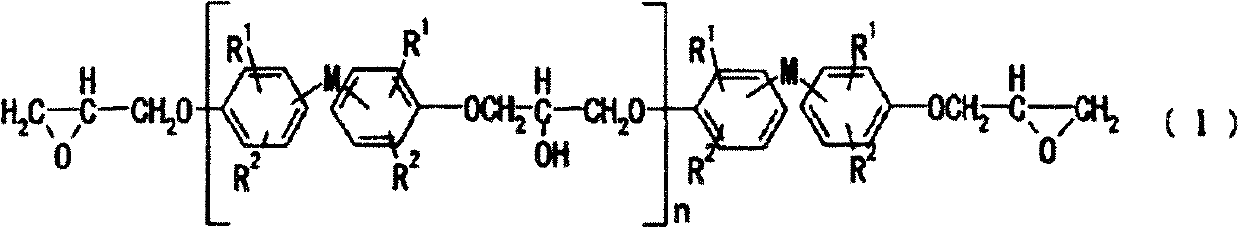

A photocurable resin, molecular technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of insufficient photocurability or adhesion of covering agents or dispersants, and achieve excellent The effect of high photocurability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

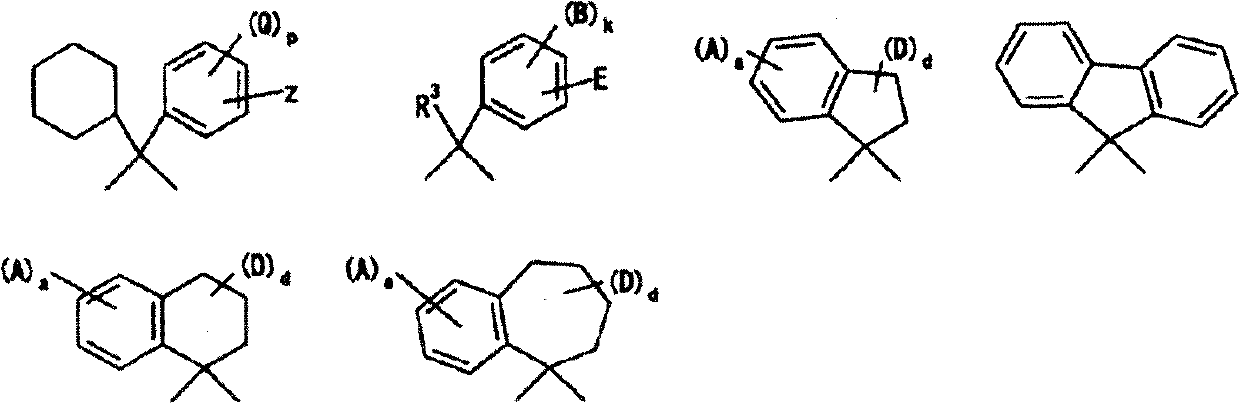

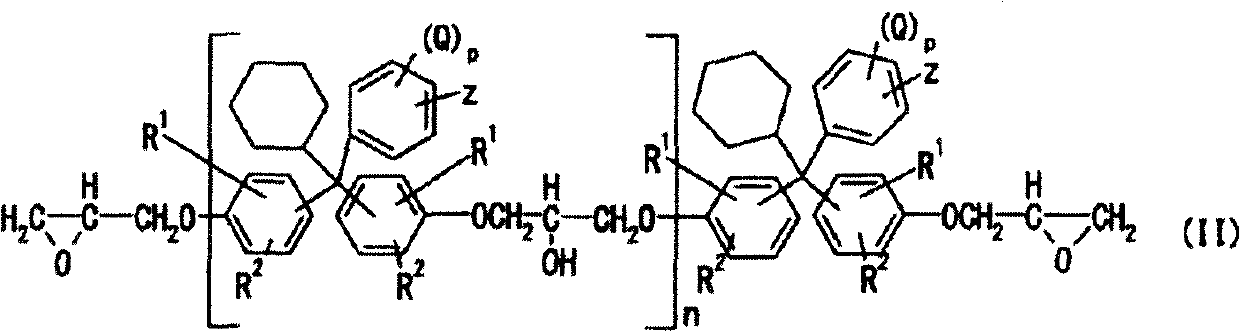

Method used

Image

Examples

Embodiment 1

[0104] [Example 1] Production of Photocurable Resin No.1

[0105] In a 1L four-necked flask with stirring device, nitrogen inlet pipe, reflux cooling pipe and thermometer, add 75.0g of bisphenol fluorene type epoxy resin (epoxy equivalent is 231) as a difunctional epoxy compound, 23.8g as Acrylic acid of unsaturated monobasic acid, 0.273g 2,6-di-tert-butyl-p-cresol, 0.585g tetrabutylammonium chloride and 65.9g propylene glycol-1-monomethyl ether-2-acetate at 90°C The mixture was stirred for 1 hour at 100° C., 1 hour at 110° C., 1 hour at 110° C. and 14 hours at 120° C. to obtain component (C). After cooling to room temperature, 55.6 g of commercially available polyethylene glycol monomethyl ether (Uniox M-1000 manufactured by NOF Corporation) with a number average molecular weight of 1000 as the component (B) and 2,4 - 28.6 g of toluene diisocyanate, 0.182 g of dibutyltin dilaurate, and 206 g of propylene glycol-1-monomethyl ether-2-acetate were stirred at 70° C. for 2 hours....

Embodiment 2

[0107] [Example 2] Production of Photocurable Resin No.2

[0108] 1, the synthesis of 1-bis(4-hydroxyphenyl)indan

[0109] In a 2L four-neck flask equipped with a stirring device, a nitrogen inlet pipe, a reflux cooling pipe, and a thermometer, add 200g of indanone and 855g of phenol under a nitrogen atmosphere, slowly add 59.4g of sulfuric acid dropwise at 40°C, and then dropwise add 16.1 g 3-mercaptopropionic acid. After the dropwise addition, it was stirred at 55° C. for 20 hours, 300 g of ethyl acetate and 50.4 g of 48% by weight aqueous sodium hydroxide solution were added for neutralization, and the precipitated crystals were filtered to obtain 224 g of a crude product. The crude product was dissolved in 1450 g of ethyl acetate, washed with 500 g of 5% by weight ammonium acetate aqueous solution until the pH of the organic layer reached 4 to 5, and 50 g of anhydrous magnesium sulfate was added to the organic layer after the liquid was separated, and dried . The solve...

Embodiment 3

[0115] [Example 3] Production of Photocurable Resin No.3

[0116] In a 500mL four-neck flask with a stirring device, a nitrogen inlet tube, a reflux cooling tube, and a thermometer, add 1,1-bis[4-(2,3-epoxypropoxy) as a difunctional epoxy compound Phenyl]-1-(4-biphenyl)-1-cyclohexylmethane (279 epoxy equivalents) 33.0g, 6.22g acrylic acid as unsaturated monobasic acid, 0.082g 2,6-di-tert-butyl p- Cresol, 0.153 g tetrabutylammonium chloride and 10.5 g propylene glycol-1-monomethyl ether-2-acetate, stirred at 90°C for 1 hour, at 100°C for 1 hour, at 110°C After stirring for 1 hour and 17 hours at 120° C., component (C) was obtained. Cool to room temperature, add 16.9 g of monomethyl ether of a commercially available number average molecular weight of 1000 ethylene glycol / propylene glycol copolymer as (B) component, 8.34 g of isophorone diisocyanate as (A) component, 0.055 g dibutyltin dilaurate and 62.9 g propylene glycol-1-monomethyl ether-2-acetate, stirred at 70°C for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com