Method for forging annular cylinder by aid of electroslag remelted hollow blank

An electroslag remelting and hollow technology, which is applied in metal processing equipment and other directions, can solve problems such as lengthy process flow, uneven deformation, material waste, etc., and achieve the effect of improving the mechanical properties of products, improving the internal quality, and developing dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

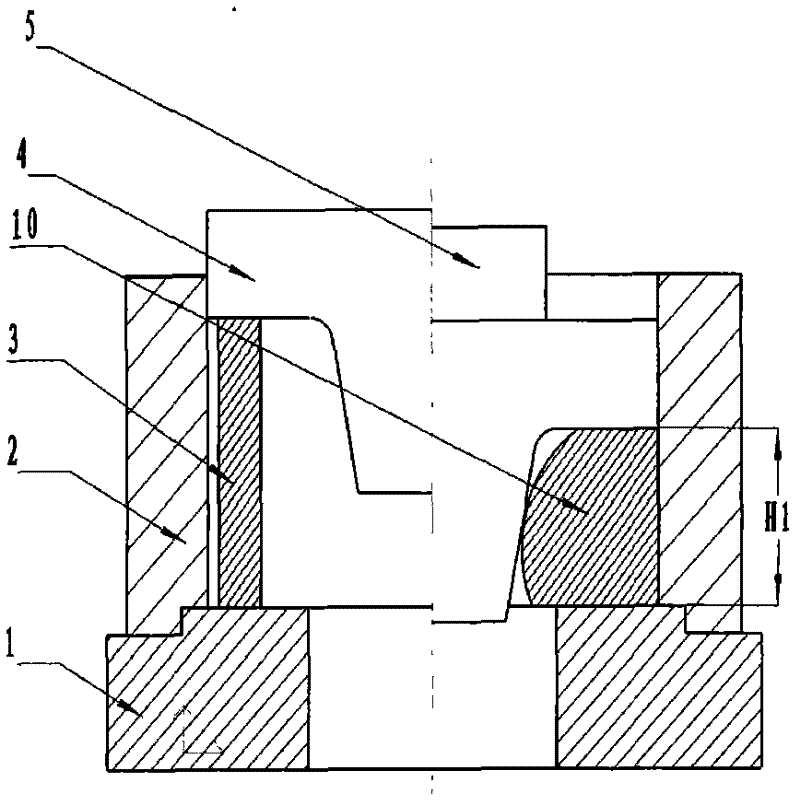

[0020] 1. Such as figure 1 As shown, the upsetting spool 1 and the upsetting drum die 2 assembled with it are placed on the press platform, and the heated electroslag remelted hollow blank 3 is placed on the upsetting drum 2 On the drain plate 1 for internal upsetting, put the "T" type anvil 4 for upsetting on the hollow blank 3 of electroslag remelting, and start the press to apply the "T" type anvil 4 to the hollow blank 3 through the upsetting. Press to produce upsetting deformation until the upper surface of the upsetting "T"-shaped anvil 4 is flush with the upper end of the upsetting drum mold 2, and stop applying pressure, and place a cushion block 5 on the upsetting "T"-shaped anvil 4, Start the press again through the spacer block 5 and upsetting with the "T" type anvil 4 to continue to press the hollow blank 3 until the hollow blank 3 reaches the set height H1, and the upsetting blank 10 is obtained;

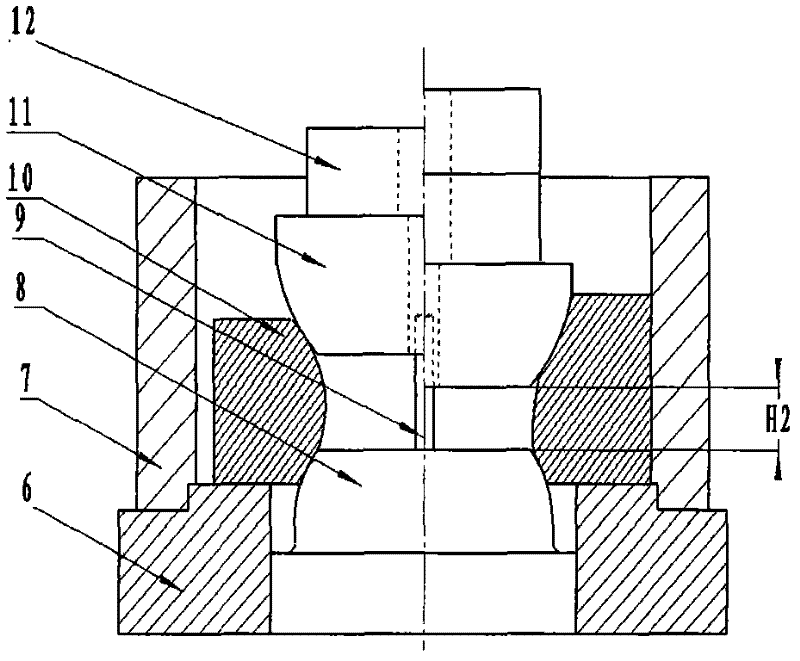

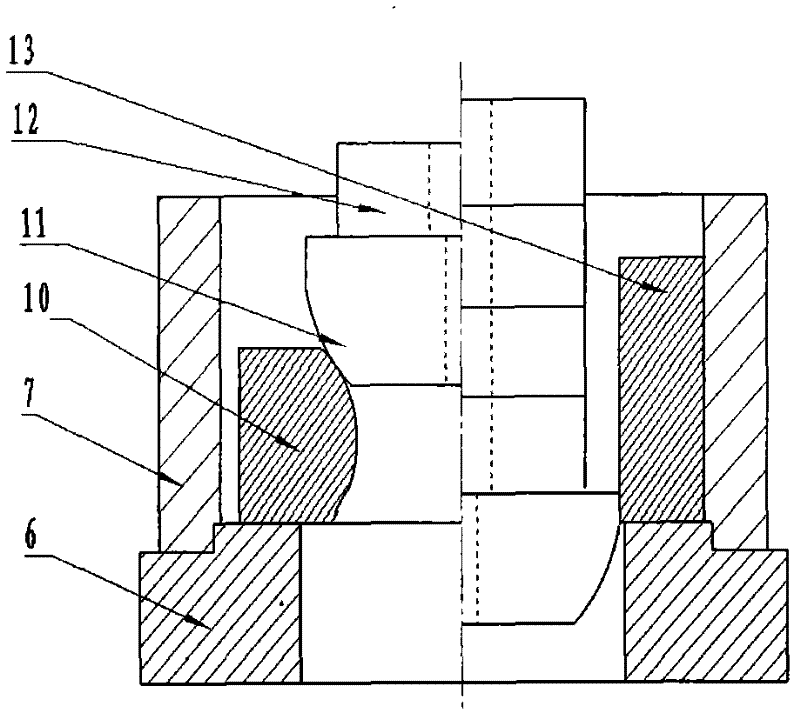

[0021] 2. Such as figure 2 , image 3 As shown, the lower positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com