Nickel-based superalloy for missile launching device and manufacturing process of nickel-based superalloy for missile launching device

A nickel-based superalloy and missile launch technology, which is applied in the field of rudder and sail of aviation missiles, can solve the problems of low tensile strength and plasticity, achieve good product performance, improve product mechanical properties and use requirements, and process operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

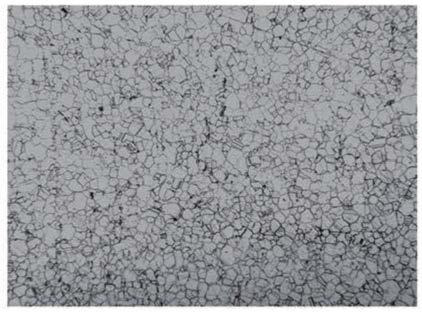

Image

Examples

Embodiment 1

[0034] 1. Nickel-based superalloy 18Cr-4W-4Mo, as shown in Table 2, lists the chemical composition of the five furnaces

[0035] Table 2 Chemical composition of nickel-based superalloy 18Cr-4W-4Mo

[0036]

[0037] 2. Hot rolled flat steel process

[0038] The flat steel rolling process system is shown in Table 3;

[0039] Table 3 Flat Steel Rolling Process:

[0040]

[0041] 3. The passing system of the alloy is 1130°C, heat preservation for 300min, air cooling +810°C, heat preservation for 600min, air cooling treatment, the mechanical performance test results are shown in Table 4;

[0042] Table 4 Mechanical property test results

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com