Clamping type radiator

A heat sink, clip-on technology, applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of waste of energy consumption, difficult production, etc., to improve heat dissipation performance, heat dissipation Excellent performance, the effect of excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

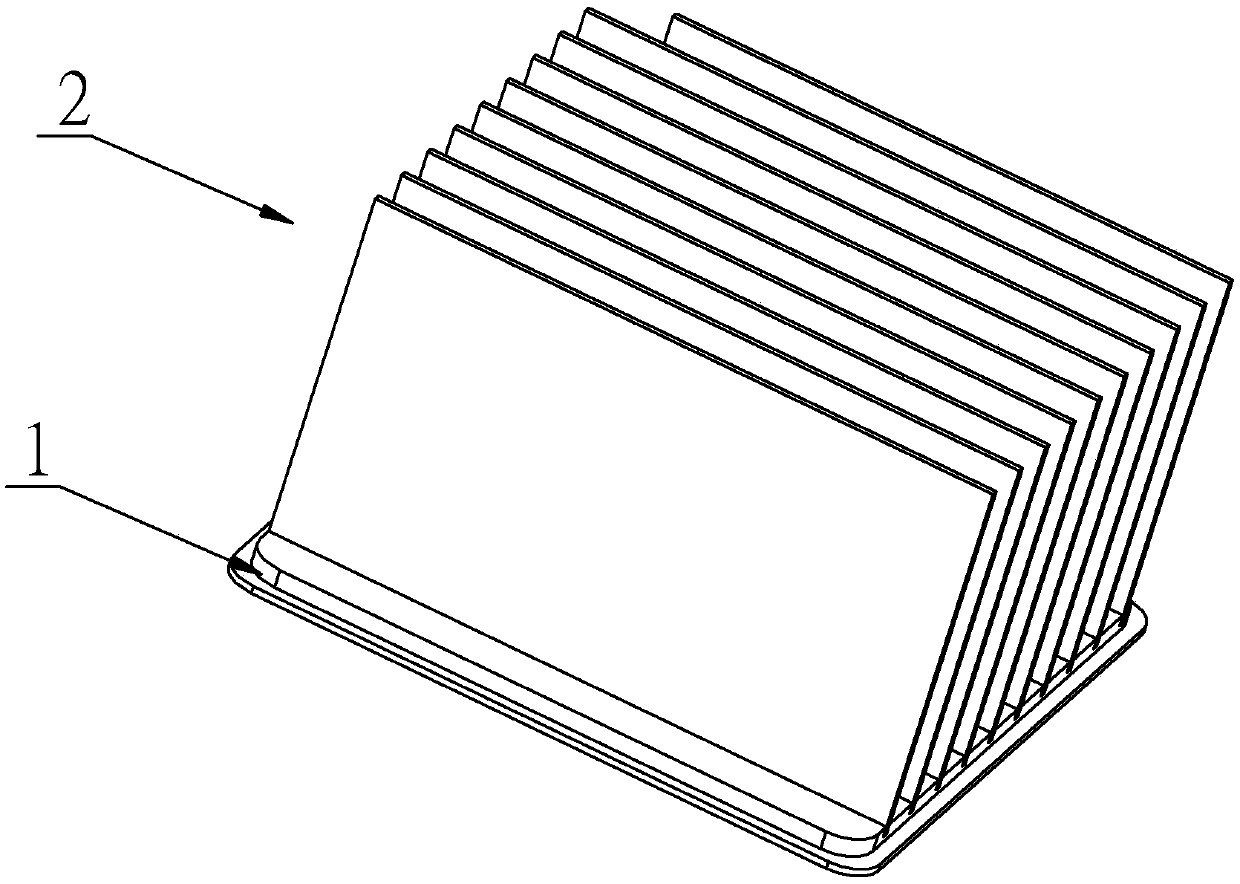

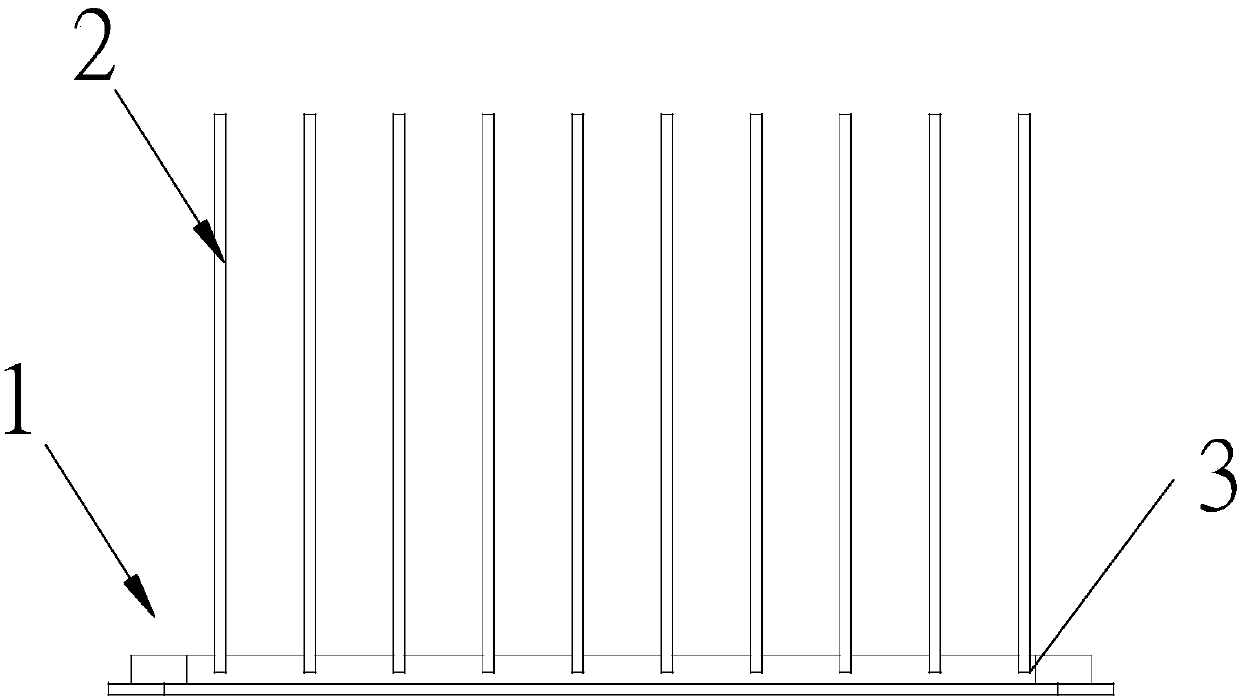

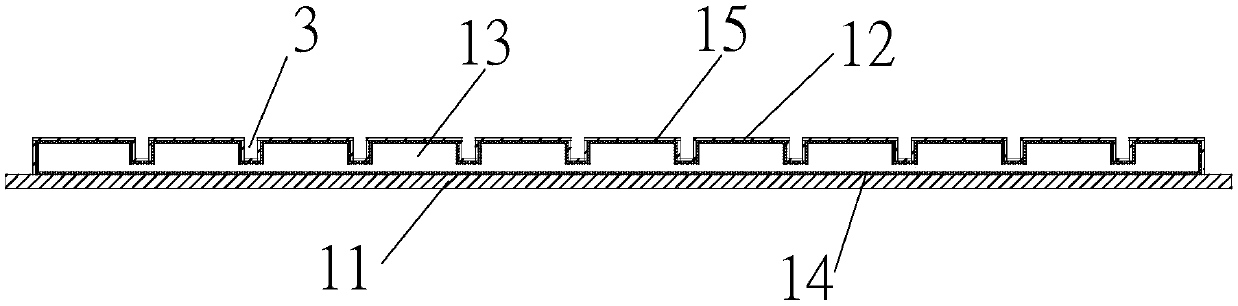

[0029] The invention discloses a clamping radiator, referring to Figure 1 to Figure 4 , including a vapor chamber 1 , preferably a copper vapor chamber, and fins 2 connected to the vapor chamber 1 . Specifically, the vapor chamber includes an evaporating surface 11 and a condensing surface 12, the evaporating surface 11 and the condensing surface 12 form a closed cavity 13, and the closed cavity 13 is filled with a liquid working fluid. The filling amount of the liquid working medium should be greater than or equal to more than half of the volume of the sealed inner cavity, which is not only conducive to the flow of the liquid working medium, but also conducive to increasing the heat dissipation effect. A first capillary layer 14 is sintered on the inner surface of the evaporation surface 11 , and a second capillary layer 15 is sintered on the inner surface of the condensation surface.

[0030] In order to improve the heat diffusion rate from the bottom plate to the capillar...

Embodiment 2

[0033] The invention discloses a clamping radiator, referring to Figure 5 to Figure 8 , including a vapor chamber 1 , preferably a copper vapor chamber, and fins 2 connected to the vapor chamber 1 . Specifically, the vapor chamber includes an evaporating surface 11 and a condensing surface 12, the evaporating surface 11 and the condensing surface 12 form a closed cavity 13, and the closed cavity 13 is filled with a liquid working fluid. The filling amount of the liquid working medium should be greater than or equal to more than half of the volume of the sealed inner cavity, which is not only conducive to the flow of the liquid working medium, but also conducive to increasing the heat dissipation effect. A first capillary layer 14 is sintered on the inner surface of the evaporation surface 11 , and a second capillary layer 15 is sintered on the inner surface of the condensation surface.

[0034] In order to improve the heat diffusion rate from the bottom plate to the capillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com