Patents

Literature

63 results about "ANFO" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ANFO (or AN/FO, for ammonium nitrate/fuel oil) is a widely used bulk industrial explosive. Its name is commonly pronounced as "an-fo". It consists of 94% porous prilled ammonium nitrate (NH₄NO₃) (AN), which acts as the oxidizing agent and absorbent for the fuel, and 6% number 2 fuel oil (FO).

Anfo explosive and manufacturing method thereof

ActiveCN101544524ASimple recipeEfficient production processExplosive working-up apparatusANFOFuel oil

The invention provides anfo explosive with low explosion velocity and a manufacturing method thereof. The anfo explosive comprises 82 to 97 percent of crushed porous granular ammonium nitrate and 3 to 7 percent of fuel oil in terms of mass. A formulation of the anfo explosive is simple, high explosive and heavy metal or heavy metal oxides are not contained, and a production process is efficient, safe and environment-friendly. Moreover, the anfo explosive has wide density adjusting range and is easy to explode; the performance of the explosive is convenient to control, the adjusting method is more, and the adjusting range is large; and the raw material sources are wide, the production cost is low, and the method is suitable for industrialized production.

Owner:BEIJING BGRIMM YIBO TECH

Viscous and granular anfo (ammonium nitrate and fuel oil) explosive and preparation method thereof

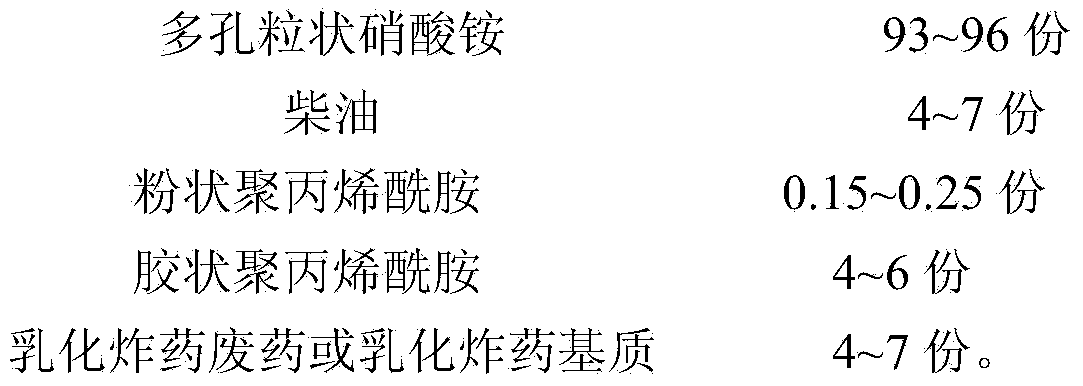

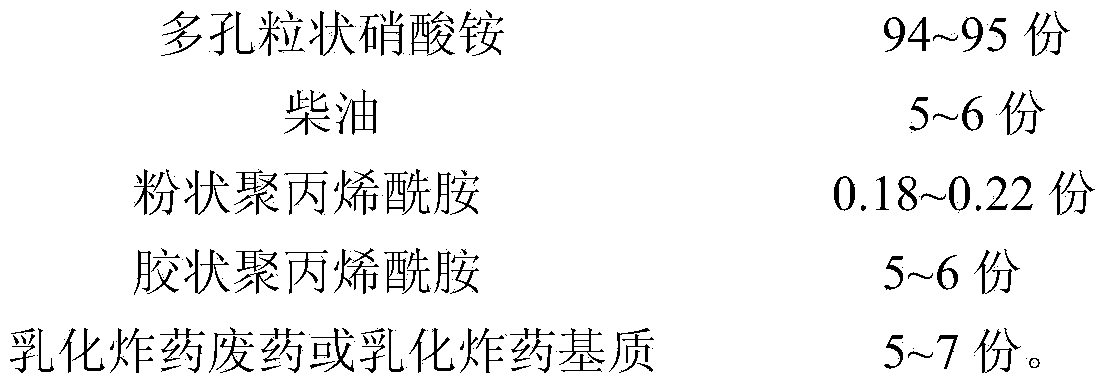

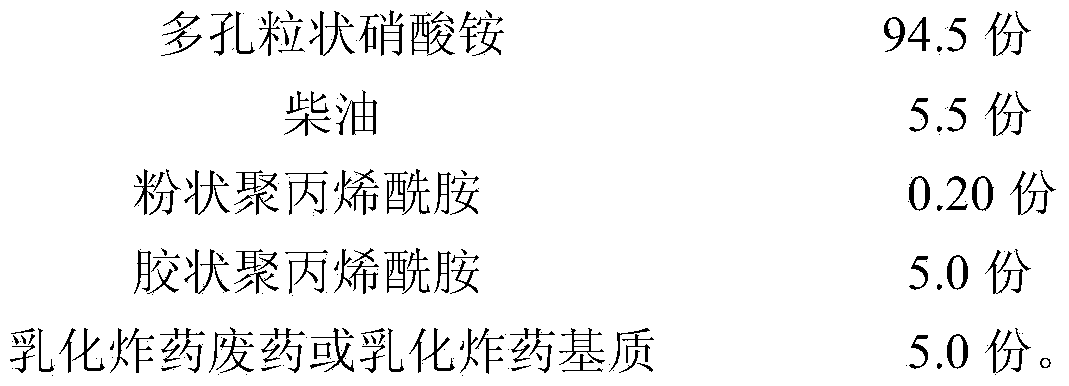

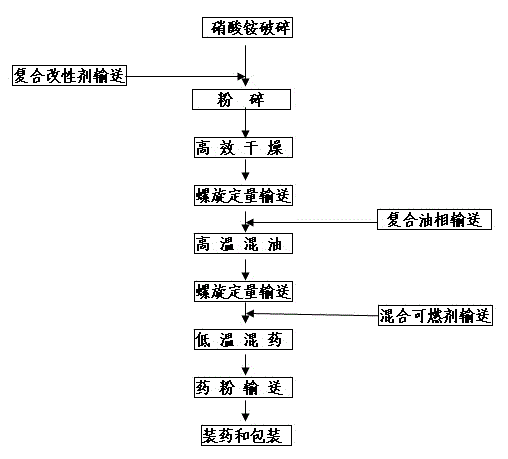

The invention relates to a viscous and granular anfo (ammonium nitrate and fuel oil) explosive and a preparation method thereof. The explosive comprises the following raw material components in parts by weight: 93-96 parts of porous granulated ammonium nitrate, 4-7 parts of diesel oil, 0.15-0.25 part of powdered polyacrylamide, 4-6 parts of colloidal polyacrylamide and 4-7 parts of a waste emulsion explosive or an emulsion explosive matrix. The viscous and granular anfo explosive disclosed by the invention effectively uses the waste emulsion explosive or the emulsion explosive matrix, well solves the problems of safety treatment on the waste emulsion explosive or the emulsion explosive matrix, is simple in preparation process and convenient in production, and is convenient for large-scale production and application of blasting sites.

Owner:SHANDONG TIANBAO CHEM

Low-detonation velocity anfo explosive and preparation method thereof

The invention relates to a low-detonation velocity anfo explosive and a preparation method thereof. The low-detonation velocity anfo explosive comprises 77-88 parts of modified powdery anfo explosive, 10-20 parts of porous granulated ammonium nitrate and 2-3 parts of polystyrene foam plastic microballoon, wherein the modified powdery anfo explosive mainly comprises 74.54-84.66 parts of crystallized ammonium nitrate, 0.15-0.26 part of modifying agent and 2.31-3.08 parts of compound oil phase; and the compound oil phase comprises 1.71-2.12 parts of paraffin, 0.58-0.86 part of rosin and 0.02-0.06 part of Span 80 emulsifying agent. The preparation method comprises the following steps of: mixing the crystallized ammonium nitrate and the modifying agent, crushing and drying; and then mixing with the compound oil phase; finally adding the porous granulated ammonium nitrate and the polystyrene foam plastic microballoon and uniformly mixing to obtain the low-detonation velocity anfo explosive with the density less than 0.55g / cm<3> and the detonation speed less than 2,600m / s. The explosive has the advantages of favorable particle flowability, convenience for filling into a blast hole, low detonation velocity, low density and capability of meeting the requirements for using the explosive on smooth surface blasting and presplitting blasting of mines, highways, railways and open-air deep-hole slopes.

Owner:HUAINAN SHUNTAI CHEM

Modified ammoium nitrate fuel oil (ANFO) explosive and preparing method thereof

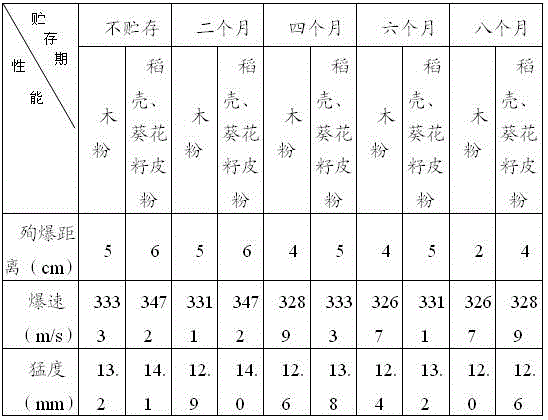

The invention relates to a new material for a modified ANFO explosive, and in particular relates to a modified ANFO explosive and a preparing method thereof by using rice hull powder and sunflower seed hide powder as a combustible agent. The modified ANFO explosive comprises, by matched group, 91.5%-93.5wt% of ammonium nitrate, 0.2-0.4wt% of compound modifying agent, 3.0-4.0wt% of compound oil phase and 3.5-4.5wt% of combustible agent, wherein the matching ratio total of raw materials is 100%, the compound modified agent is one or more of octadecylamine phosphate, sulfonate or borate, the compound oil phase is one or more of paraffin, soap wax, asphalt, three line oil and microcrystalline wax, and the combustible agent is a mixture of the rice hull powder and the sunflower seed hide powder. According to the modified ANFO explosive and the preparing method thereof, rice hull powder serves as the combustible agent of the modified ANFO explosive, not only the explosion performance of the explosive is improved, but also the product physical property is improved, and the product storage life is prolonged.

Owner:LIAONING HONGSHAN CHEM

High density ANFO

The present invention relates to a high density ammonium nitrate-fuel oil ("ANFO") blasting composition comprising an organic liquid fuel and porous prilled ammonium nitrate of high bulk density, small particle size and good oil absorption capacity.

Owner:DYNO NOBEL INC

High-powered modified ANFO containing spongy titanium powder and method for preparing same

The invention belongs to titanium sponge powder-containing high-strength modified ammonium nitrate fuel oil explosive used in engineering blasting and a method for making the same. The ammonium nitrate fuel oil explosive is powdery explosive consisting of powdery ammonium nitrate, wood flour, modified addition agent, a compound oil phase material and titanium sponge powder. The high-strength modified ammonium nitrate fuel oil explosive does not contain high explosives such as TNT, and contains titanium sponge powder; moreover, the explosive has a simple manufacturing method and better explosion properties than ammonium nitrate fuel oil explosive.

Owner:PANZHIHUA UNIV

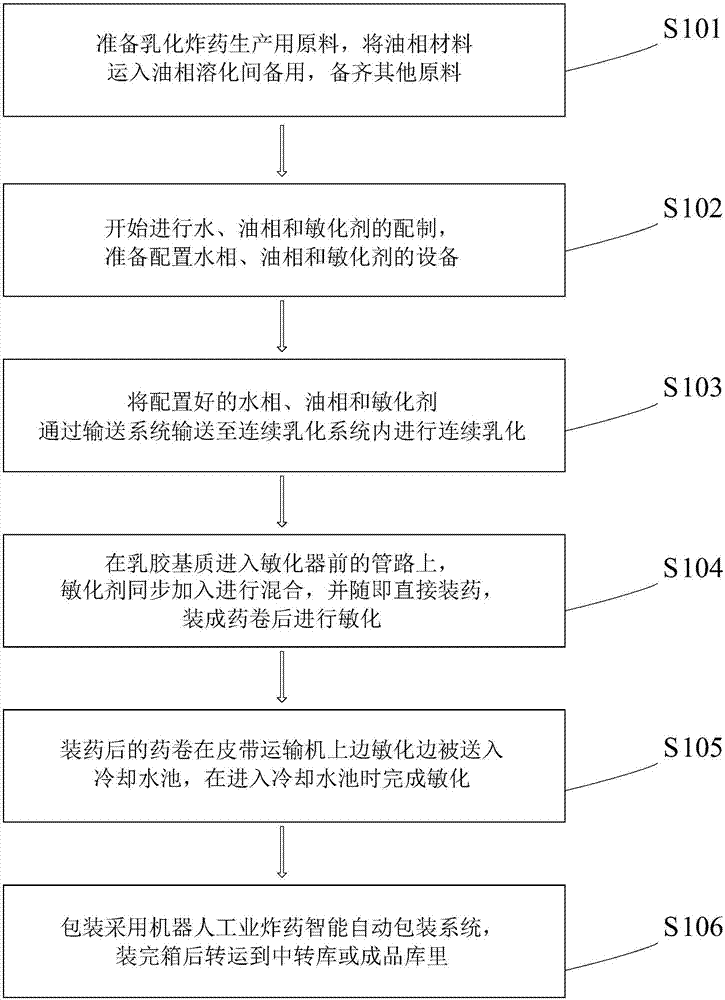

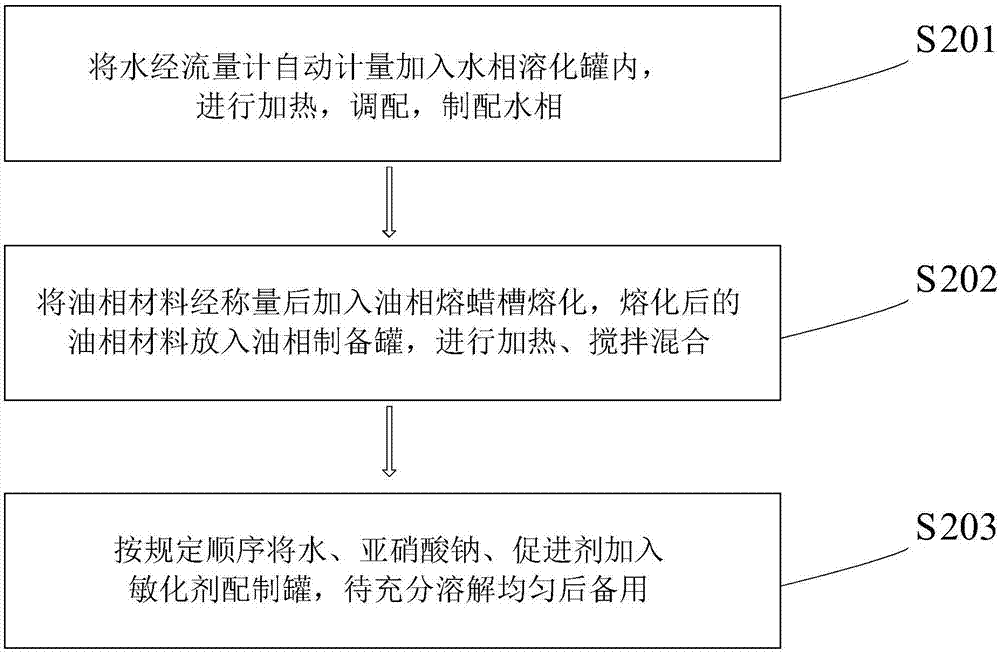

Safety production process of emulsified granular ammonium oil explosive

PendingCN107540490AGuaranteed operational safetySafe preparationExplosive working-up apparatusParticulatesANFO

The invention provides a safe production process of emulsified granular ammonium explosives, belonging to the field of explosive preparation methods. The specific steps of the safe production process of the emulsified granular ammonium explosives are raw material preparation, preparation of water, oil phase and sensitizer, continuous emulsification, Charge sensitization, coil cooling and packaging and storage processes. The preparation method of the invention is simple and safe, and the automatic packaging and automatic storage methods greatly reduce the labor intensity, ensure the production safety, and at the same time solve the problems that the original preparation method is unsafe, the operation labor intensity is high, and the operation method is not practical. , in order to make the preparation safer, ensure the safety of personnel operation, and improve the preparation efficiency.

Owner:JIANGXI JIAN GUOTAI SPECIAL CHEM

Rock type low-temperature anti-caking modified ANFO (Ammonium Nitrate Fuel Oil) explosive and preparation method thereof

The invention discloses a rock type low-temperature anti-caking modified ANFO (Ammonium Nitrate Fuel Oil) explosive and a preparation method thereof. The ANFO explosive is prepared from the following raw materials in percentages by mass: 90.5-92.0% of ammonium nitrate, 4.5-5.5% of wood flour, 0.3-0.5% of composite modifying agent, and 3.0-4.0% of composite oil phase, wherein the passing rate of the wood flour on a 40-mesh screen is not less than 90wt%, the kinematic viscosity of the composite oil phase at 100 DEG C is 12-16mm<2> / s, and the drop melting point of the composite oil phase is 20-32 DEG C. The preparation method of the ANFO explosive comprises the following steps: drying the ammonium nitrate, adding the composite modifying agent into the dried ammonium nitrate for modification, adding the composite oil phase and the wood flour into the modified ammonium nitrate and uniformly mixing, conveying the uniform mixture into a continuous type ball mill by using a feed screw conveyor for continuous milling and mixing, cooling to be not higher than 40 DEG C, and at last carrying out charging and packaging by using a full-automatic charging machine to obtain a product with the water content not high than 0.15%. The production process of the ANFO explosive disclosed by the invention is safe and reliable, the raw materials can be uniformly mixed, the free-running property of the produced explosive is improved, and the anti-caking capacity of the explosive at a low-temperature state is improved.

Owner:WEIFANG LONGHAI FOLK DYNAMLTE

Development of new high energy blasting products using demilitarized ammonium picrate

InactiveUS6214140B1Extend fractureHigh viscosityBlasting cartridgesNitrated aromatic explosive compositionsChemistryANFO

As has been established, the use of energetic materials, generated by manufacturer's excess and / or demilitarization projects, as ingredients in commercial blasting explosives is a feasible and environmentally acceptable method of handling them. Ammonium picrate is used as an explosive charge in the manufacturing of conventional ammunition rounds, such as large caliber navy guns. The present invention is directed to the use of recovered ammonium picrate in commercial blasting agent compositions, that include watergel slurries, ANFO, HANFO-blends and emulsion based blasting agents. These new blasting agents exhibit favorable cost for performance characteristics and have found a use for recovered ammonium picrate, which would heretofore have been incinerated or otherwise disposed of at significant cost.

Owner:UTEC CORPORATION LLC

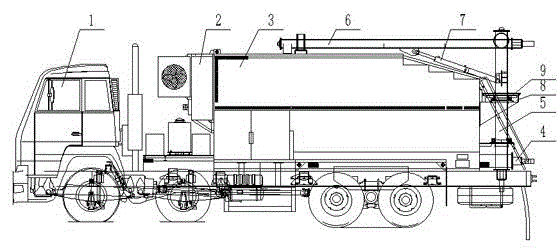

Elevated type on-site granular ANFO (Ammonium Nitrate Fuel Oil) explosive mixed loading automobile

InactiveCN103983150ASimple structureReasonable structureBlastingItem transportation vehiclesHydraulic cylinderVehicle frame

The invention relates to a mixed loading explosive automobile, and specifically provides an elevated type on-site granular ANFO (Ammonium Nitrate Fuel Oil) explosive mixed loading automobile, which is simple and reasonable in structure and convenient, safe and reliable in operation. The technical scheme adopted by the invention is that the elevated type on-site granular ANFO explosive mixed loading automobile comprises an automobile body, wherein a chassis of the automobile body is provided with a fuel oil device and a dry material box, the bottom part of a material cabin of the dry material box is provided with a box body helix, a frame at the rear part of the automobile body is vertically provided with a vertical helix, the lower part of the vertical helix is communicated with the box body helix, the top part of the vertical helix and a top helix are communicated and hinged together, a cylinder body of a hydraulic cylinder is hinged to a fixing frame at the middle part of the vertical helix, and a piston rod of the hydraulic cylinder is hinged to the middle part of the top helix. The elevated type on-site granular ANFO explosive mixed loading automobile disclosed by the invention is mainly used for mixed loading of ANFO explosive.

Owner:SHANXI HUIFENG SPECIAL AUTOMOBILE

On-site mixing method and car of ground and underground viscous porous granular ammonium nitrate fuel oil (ANFO) explosive

InactiveCN103449941AIncrease stickinessImprove product qualityBlastingExplosive working-up apparatusANFOFuel oil

The invention relates to an on-site mixing method and car of a ground and underground viscous porous granular ANFO explosive. A loading platform which is fixed on the ground is adopted, and porous granular ammonium nitrate, composite special oil, a setting agent and a thickener are transported into the loading platform fixed on the ground by manpower through a trolley and are respectively arranged in a porous granular ammonium nitrate storage tank, a composite special oil storage tank, a setting agent storage tank and a thickener storage tank on the on-site mixing car; after that, the on-site mixing car is driven to a blasting site, and viscous porous granular ANFO explosives can be obtained by mixing the porous granular ammonium nitrate, the composite special oil, the setting agent and the thickener; and therefore, the continuity and the automation of the preparation technology can be realized, the manufacturing process is safe and high in reliability, the explosive is good in viscidity, and a product is stable in quality and good in blasting effect. The on-site mixing method and car have the powder charge efficiency of more than 2t / h for a blast hole with phi 70mm, thus being suitable for the blast holes with more than phi 100mm of steps of a surface mine and suitable for powder charging, mining and blasting of an underground tunneling opposite hole and an underground inclined hole blast hole with phi 60-100mm.

Owner:肖代军 +1

Explosive composition, method of making an explosive composition, and method of using an explosive composition

An explosive composition is provided that is comprised of a Heavy ANFO and grain hulls. In one embodiment, the grain hulls are comprised of rice hulls. The grain hulls serve both as an inert bulking additive that reduces the density of the composition and as a sensitizer that reduces the energy needed to reliably detonate the composition. Also provided is a method for manufacturing an explosive composition comprised of Heavy ANFO and grain hulls, such as rice hulls. Additionally, a method of using an explosive comprised of ANFO and grain hulls in a mining operation is disclosed.

Owner:LDE

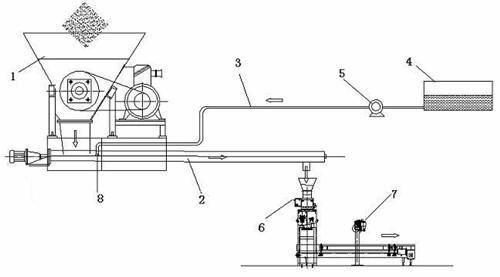

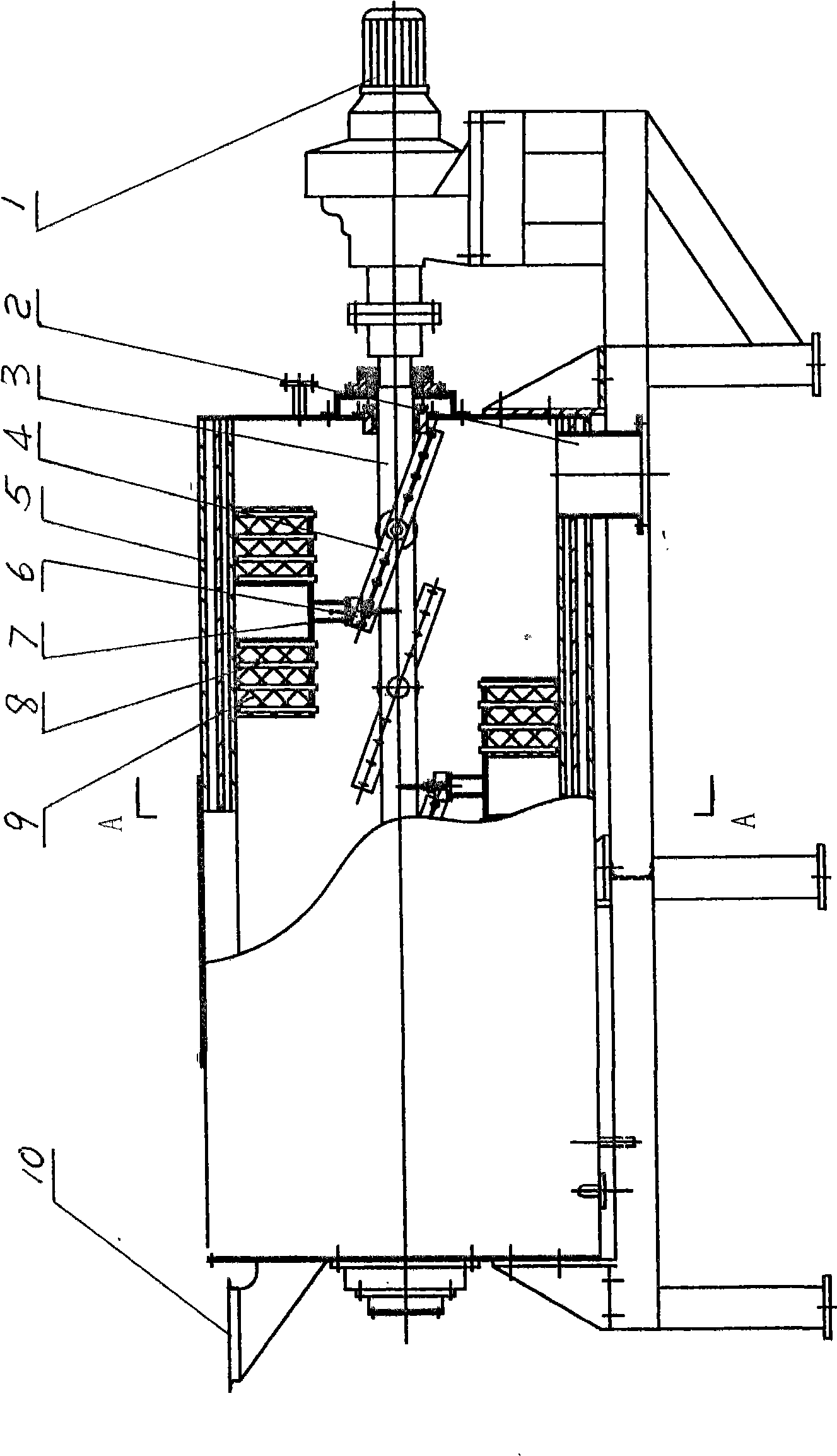

Production method and device of anfo explosives

The invention relates to a production method and a device of anfo explosives, which are characterized in that: the production method comprising the following steps of: adopting the anfo explosives which are formed by mixing crushed ammonium nitrate and diesel, taking the material, crushing, mixing, discharging, packaging, sealing and the like. The production method of the anfo explosives has a simple process, and is easy to operate and achieve streamline production; and the production device drastically improves production safety of the anfo explosives, saves labor resources and energy, is clean and safe, is easy to process and product, and reduces production cost.

Owner:DALIAN ANTAI CHEM

ANFO (Ammonium Nitrate Fuel Oil)-expanded high-explosion-velocity seismic charge

InactiveCN102040436ASimple production processReduce production energy consumptionExplosivesExplosive AgentsANFO

The invention discloses an ANFO-expanded high-explosion-velocity seismic charge which comprises the following raw materials in parts by weight: 90-94 parts of ammonium nitrate, 0.12-0.15 part of swelling agent, 0.01-0.03 part of dispersant, 0.01-0.03 part of emulsifier, 5-6 parts of compound oil phase, 0.2-0.4 part of weighting agent and 1-2 parts of aluminum powder. The seismic charge disclosed by the invention has good explosive performance, TNT (Trinitrotoluene) poisonous substances are thoroughly canceled, and substances harmful to human bodies are not added or contained; the production environment is greatly improved compared with that of a traditional AN-TNT explosive, and the damage of TNT to the bodies of personnel is prevented; and the seismic charge has a simple production process with low production energy consumption, the components of the seismic charge do not contain any highly-sensitive substances, and the safety of production and transportation processes is higher.

Owner:JINAN 456

Explosive formulation

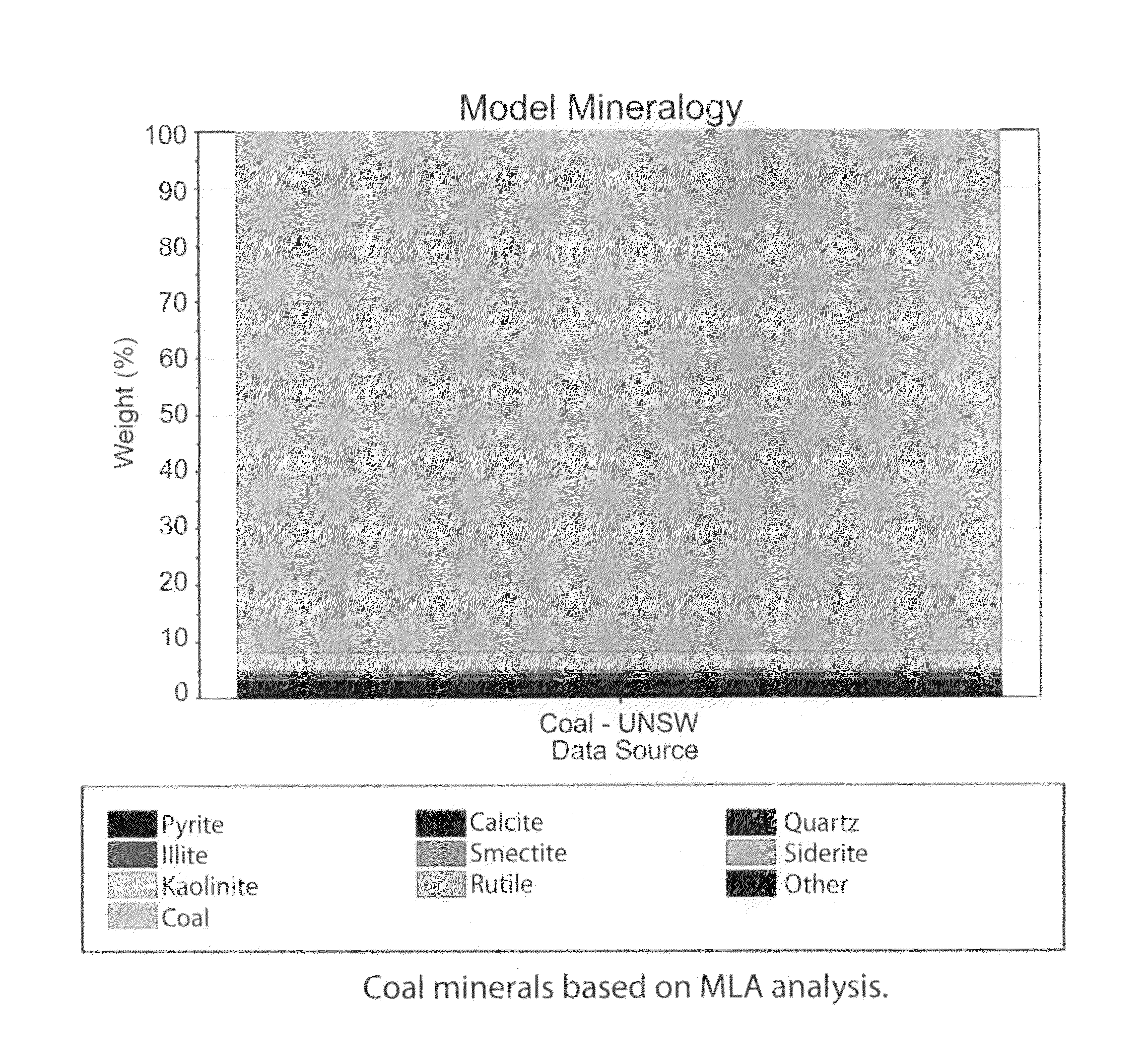

InactiveUS20070012387A1Low detonation velocityPromote resultsLoomsExplosivesSolid componentBoiling point

An explosive formulation used in blasting operations such as, but not limited to, mining operations and the like. The formulation is composed of a modified form of Ammonium Nitrate Fuel Oil (ANFO) explosives which have been modified by the incorporation of a solid fuel material. The formulation comprising a dry granular solid component, a liquid high-boiling point component of about 4% by weight, and a solid fuel material. The solid fuel material comprising vitrinite macerals, liptinite macerals, and inert macerals fusinite and semifusinite, and is characterized as (1) having a concentrate of liptinite that is higher than normal coals, and (2) having a concentrate of pseudovitrinite that is significantly lower than normal coals.

Owner:RESPONSIBLE ENERGY OPERATIONS LLC

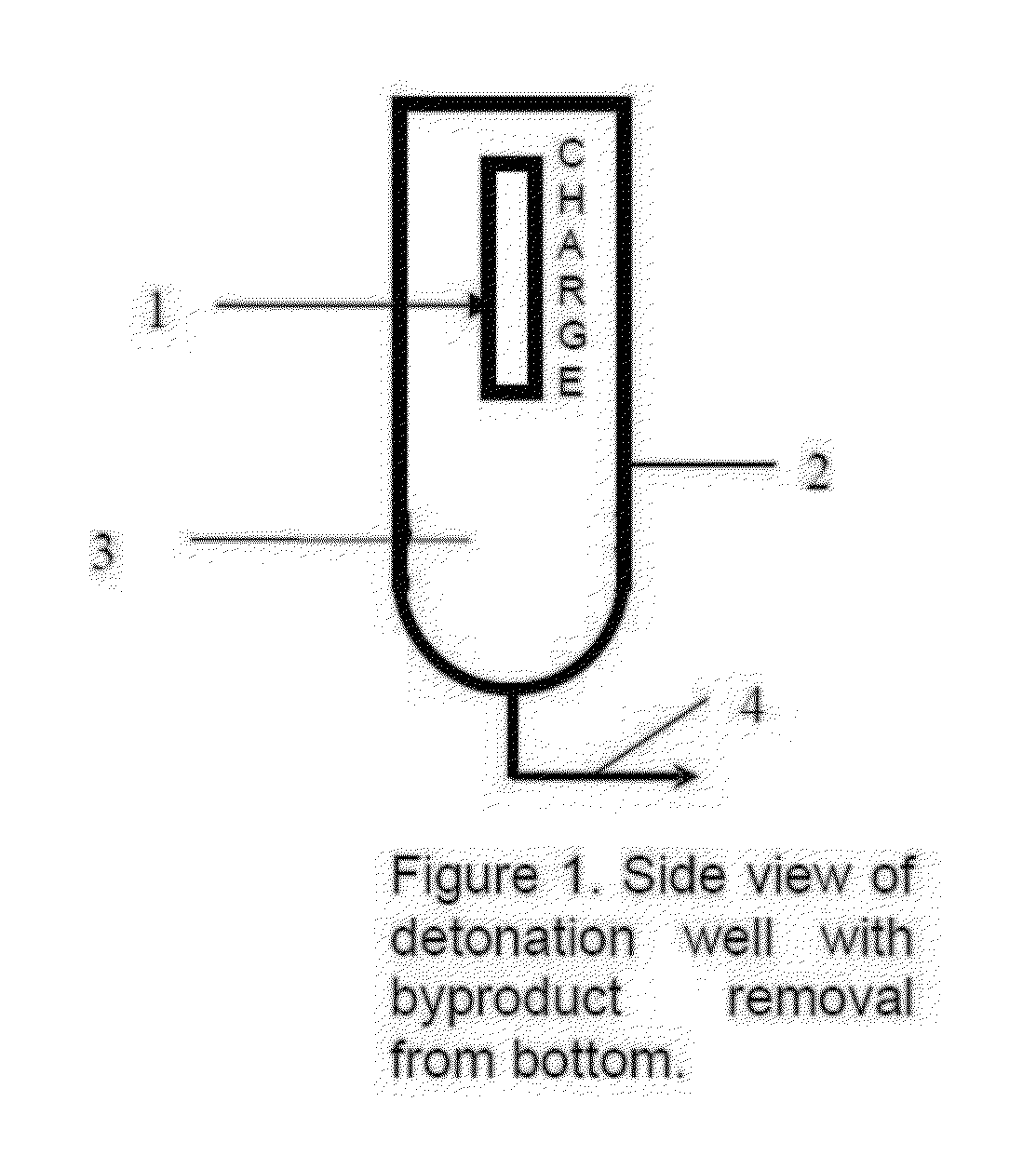

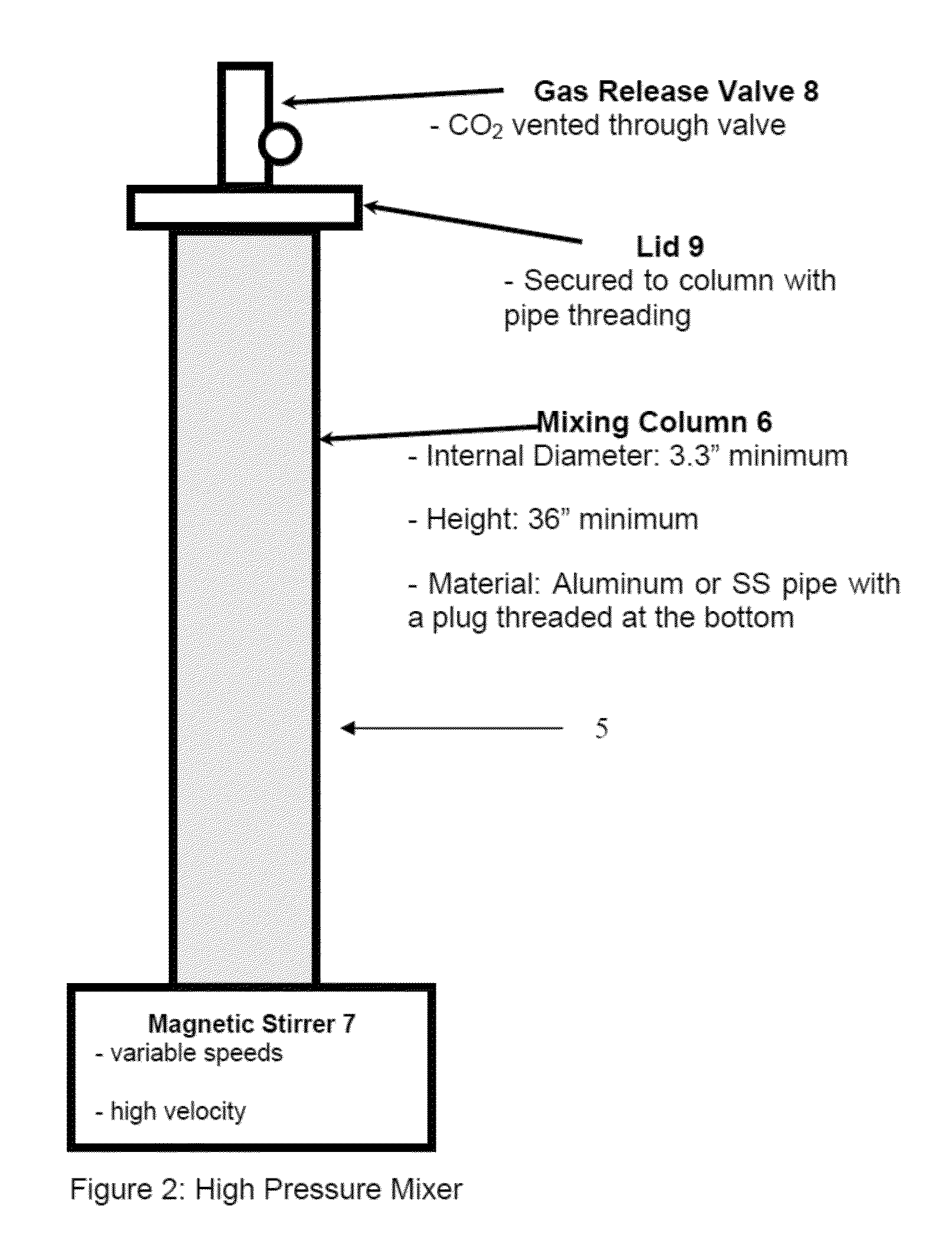

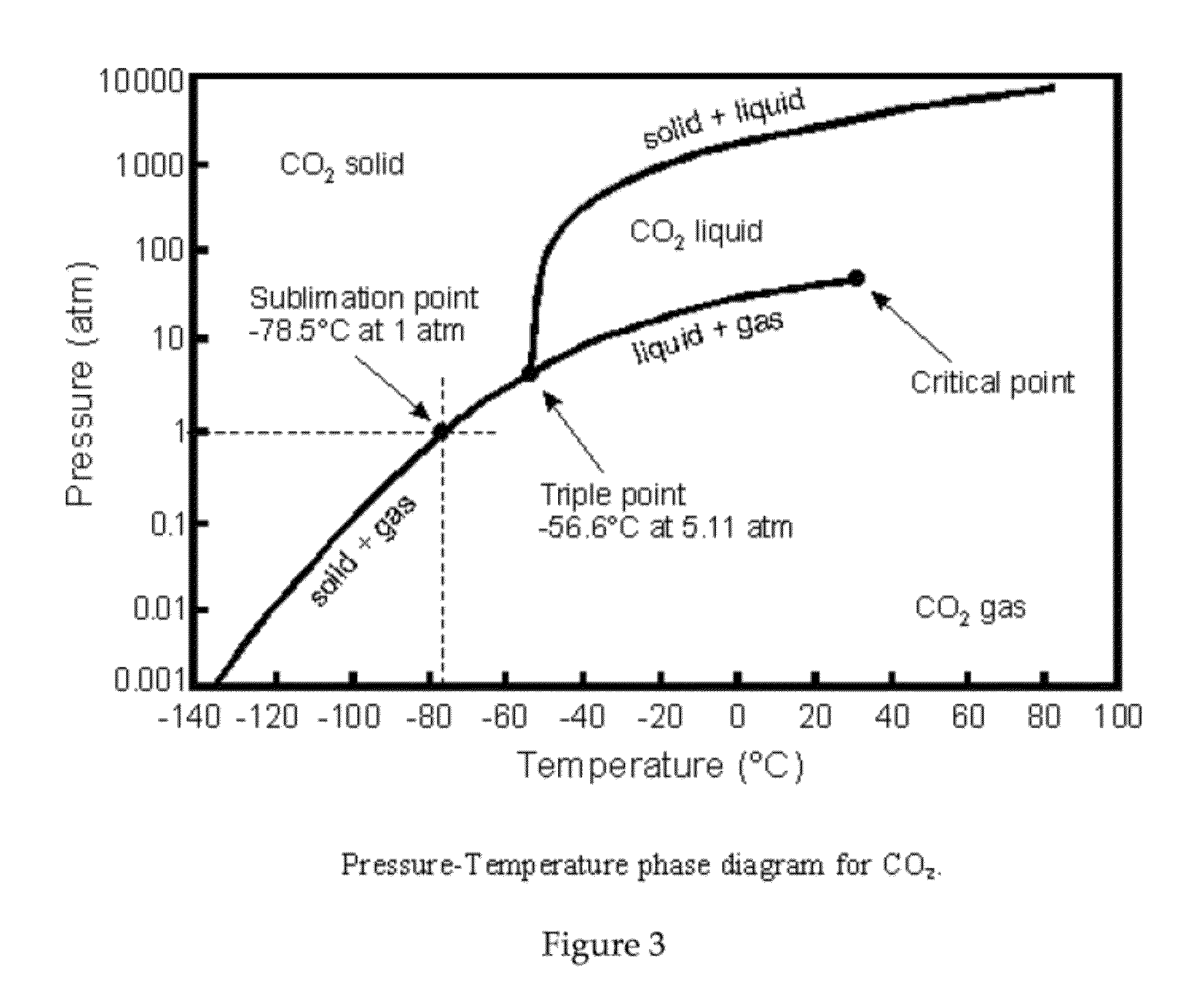

Explosive Formulations of Mixture of Carbon Dioxide and a Reducing Agent and Methods of Using Same

ActiveUS20160046538A1Low cost of ingredientsIncrease variabilityUltra-high pressure processesAluminium oxide/hydroxide preparationEmulsion explosiveANFO

The disclosure relates to embodiments of an explosive formulation comprising a detonable mixture of an oxidizing agent such as carbon dioxide, and a material that decomposes the oxidizing agent exothermically (a reducing agent), and additives that increase the mixture's shock sensitivity. The formulations may be used in a method to produce diamonds or nano oxides or in other applications that use traditional explosives such as, but not limited to: ammonium nitrate and fuel oil combinations (ANFO), watergel explosives, emulsion explosives and RDX.

Owner:SWANSON DAREN NORMAND

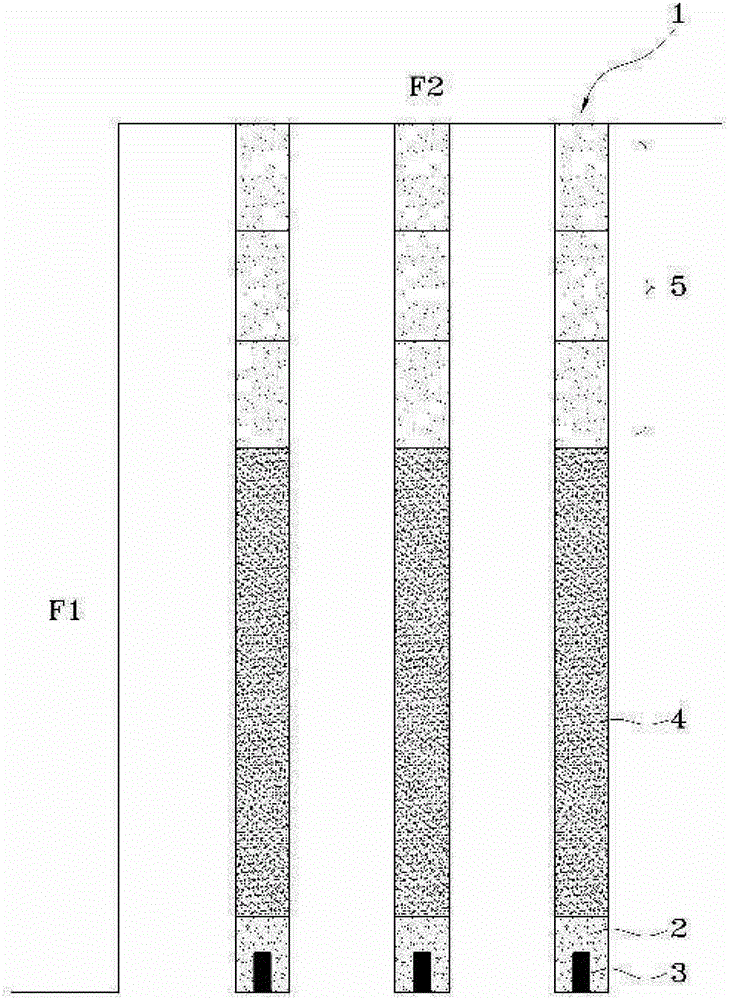

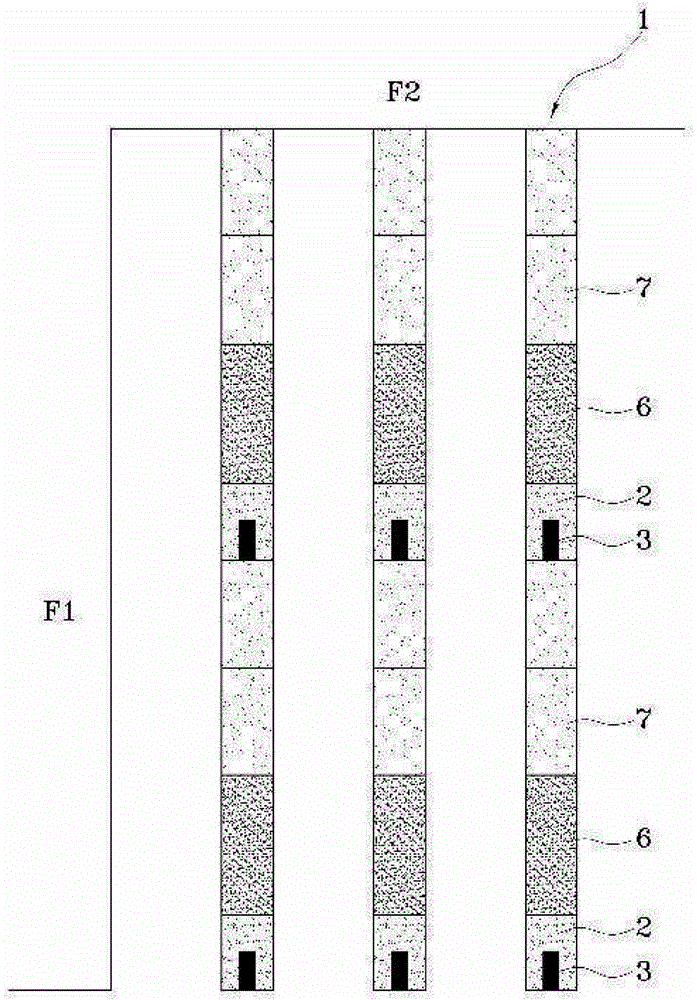

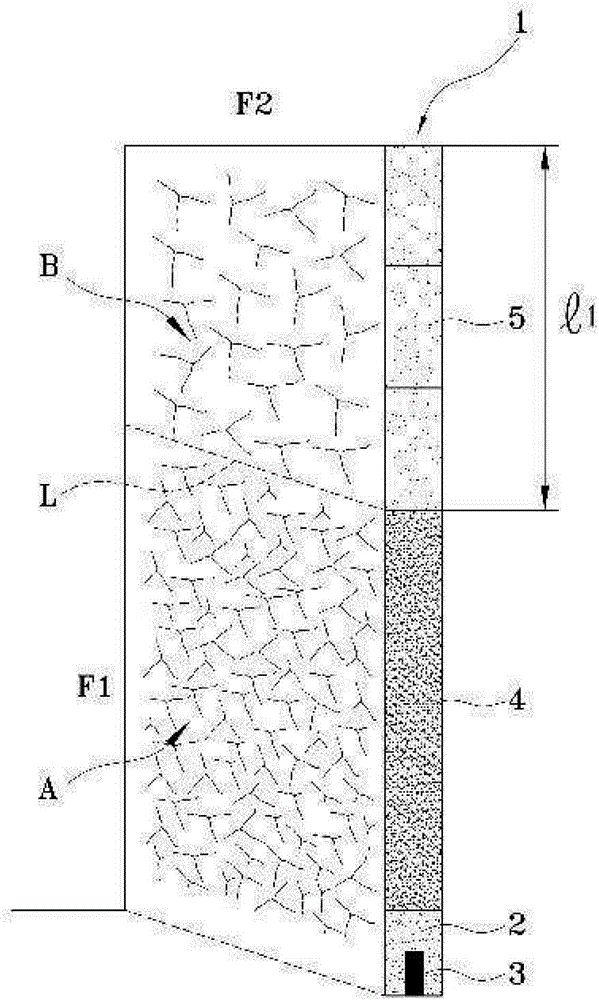

Rock Blasting Method Using Pipes Embeded In Explosive Layers Of Blast Waterhole

InactiveCN104654946AFill length extensionIncrease blast lengthBlastingDrilling machines and methodsANFORock blasting

The present invention relates to a rock blasting method using pipes embedded in explosive layers of blast waterhole, namely relates to a method for implementing the rock blasting by which a pipe body does not deform in the water in the ANFO explosive or gel bulk explosive, and by hiding the tubular pipe body recessed in the water in the water in a blasthole, and utilizing the substance in an explosive layer to fill the pipe body. Therefore, the size of the pipe body is increased correspondingly, by prolonging the filling length of the explosive towards an upper free surface, the transmission area of the laccolite at one side of the free surface at blasting is increased, and the total pressure is increased substantially, and accordingly, the whole stone generation amount at the rock blasting is reduced, the explosive use amount also can be reduced, and the damping and sonic boom are reduced.

Owner:BLASTEC KOREA LTD

Water-resisting modified ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN102351618AStrong explosive performanceGood explosive performanceExplosivesExplosive AgentsANFO

The invention relates to a preparation technology of a water-resisting modified ammonium nitrate fuel oil (ANFO) explosive, and provides a preparation technology of a non-TNT high-performance powdery ANFO explosive with high physical and chemical properties of functional powder. According to the invention, a mechanical force chemical modification technological mode is adopted. Good water resistance is provided for the explosive through the addition of a water-resisting composite oil phase rich in hydrophobic factors. The density of the explosive is reasonably regulated through the addition ofa density regulator. Therefore, good detonation sensitivity and detonating transfer performance are provided for the explosive. Compared to prior arts, the water-resisting modified ANFO explosive prepared with the technology provided by the invention is characterized by reasonable and advanced formulation. The explosive is safe and reliable, and has good damp proofing, agglomeration resisting, water resisting, and explosion performances. Therefore, the explosive is suitable for industrialized productions.

Owner:HUNAN SHINEHOOD GRP NO 169 CHEM IND

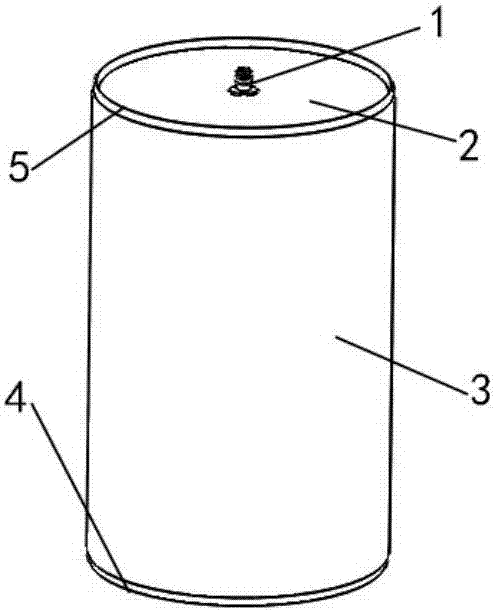

Aqueous medium spacer

PendingCN106979729ALow compressibilityThe amount of filling medium is easy to controlBlastingTEX-explosiveANFO

The invention discloses an aqueous medium spacer. The aqueous medium spacer comprises a spacer main body and a top cofferdam. The spacer main body is of a drum-shaped structure and comprises a circular top face, a circular bottom face and a side face arranged between the top face and the bottom face in a surrounding mode. A water filling nozzle is arranged on the top face, the top cofferdam is arranged on the connecting position of the top face and the side face of the spacer main body, and the top cofferdam is of a horn-shaped structure gradually expanding in the upward direction. The aqueous medium spacer has the advantages that the blasting pressure of the bottoms of blast holes is improved, and blasting vibration is reduced; the explosive load in the blast holes is reduced, and blasting unit consumption is reduced; an explosive loading structure is improved, and the explosive acting position is reasonably arranged; and waterproof spacing is achieved, and after spacing is conducted in the local water-poor blast holes, low-cost multi-hole granulous anfo explosives can be used. Compared with an air spacer, the aqueous medium spacer has the advantages that compressibility is small, the filled medium quantity is convenient to control, the influence under the climatic temperature condition is small, and the influence under the water depth pressure in the holes is small.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Water resistance additive for particulate ammonium nitrate-fuel oil (ANFO) explosives

The present invention provides for the use of at least one oil soluble polymer comprising linear polymethylene sequences with an average of 10 to 40 consecutive methylene groups to improve the water resistance of an explosive composition comprising particulate ammonium nitrate and a fuel oil, said linear polymethylene sequences with in average 10 to 40 consecutive methylene groups may be either inthe main chain or in the side chains of the oil soluble polymer.

Owner:CLARIANT INT LTD

On-site mixed and expanded ammonium nitrate explosive and production method thereof

InactiveCN102491860ASimplify the production and use processProduction and use process improvementExplosivesDetonatorANFO

The invention discloses an on-site mixed and expanded ammonium nitrate explosive and a production method thereof, belonging to the technical field of explosives and the production method thereof. The on-site mixed and expanded ammonium nitrate explosive comprises the following components in part by weight: 94-96.5 parts of expanded ammonium nitrate and 3.5-6 parts of diesel oil. The expanded ammonium nitrate is prepared in advance, and the expanded ammonium nitrate and the diesel oil are mixed by an on-site explosive mixing vehicle on a blasting site. The on-site mixed and expanded ammonium nitrate explosive does not have the detonator sensitivity, and compared with the porous granular anfo explosive, the on-site mixed and expanded ammonium nitrate explosive has lower density, high performance, and higher explosive loading volume ratio of the blasthole. In the production method, the explosive manufacturing process and the blasthole loading process are carried out on a construction site at the same time, and before mixing, only raw materials or semifinished products are stored on the blasting site, so that the production safety and the loading safety are obviously improved and a requirement on the storage stability of the explosive is greatly reduced.

Owner:XINJIANG TIANHE CHEM CO LTD

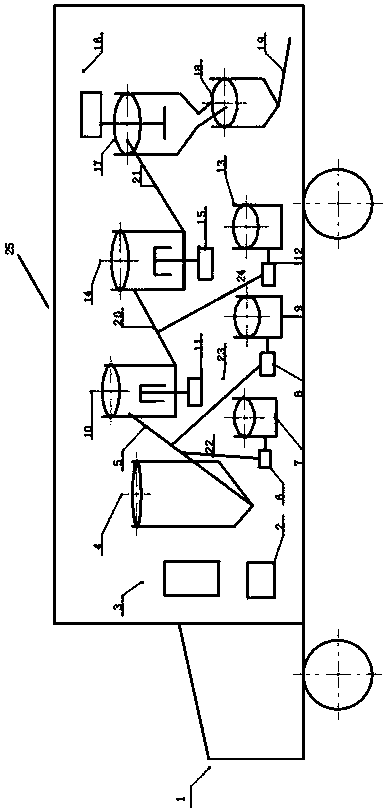

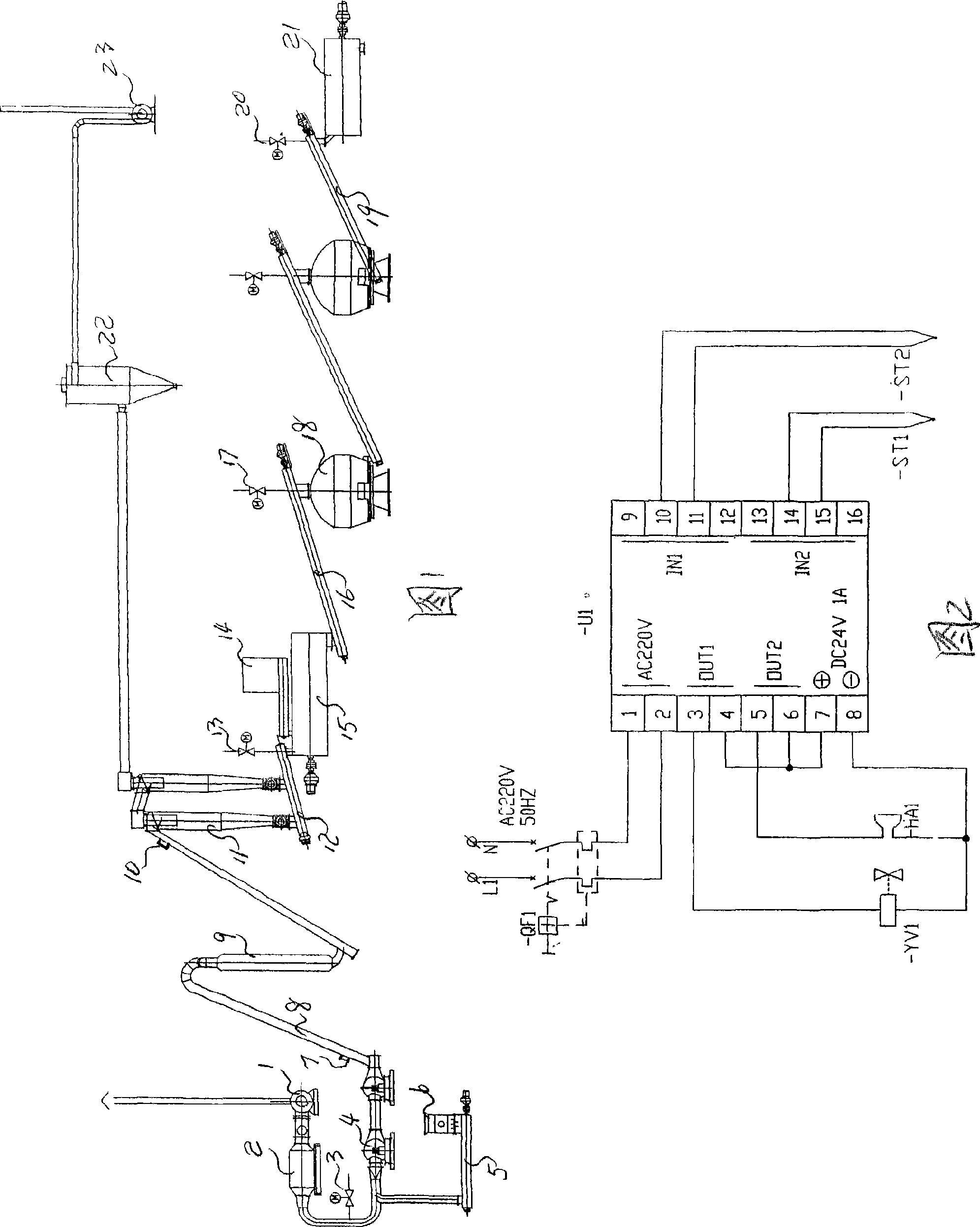

Continuous production line of modified anfo explosive

InactiveCN101519332AIncrease productivityImprove securityExplosive working-up apparatusElectricityProduction line

The invention relates to a continuous production line of modified anfo explosive, which relates to an explosive production device. The invention aims to provide a continuous production line of modified anfo explosive, which has uninterrupted continuous work and high production efficiency and safety. The technical scheme is characterized in that a pipeline between a blast fan and a cyclone separator is sequentially provided with a heater, a breaker and a cam crusher which are in series connection, the feeding port of a mixer is connected with an outlet of a quantitative spiral conveyor, an upright-type cooler and a horizontal-type cooler are connected by a spiral conveyor, a cloth-bag dust remover is arranged between air outlets of the upper parts of a draught fan and the cyclone separator, the pipeline and the mixer are respectively provided with a temperature sensor, the pipeline between the heater and the crusher and the spiral conveyor are respectively provided with electromagnetic valves connected with a fireproof rain curtain, and the electromagnetic valves are respectively electrically connected with pins 5 and 8 of a temperature controller. Pines 1 and 2 of the temperature controller are connected with a power supply. The invention is used for explosive production.

Owner:陈宁 +2

Porous granulous ammonium nitrate fuel oil mixture oil phase material and preparation method thereof

InactiveCN107311828AWide variety of sourcesStable supplyExplosivesParticulatesEnvironmental resistance

The invention discloses a porous granular ammonium oil explosive oil phase material with low cost, clean and environment-friendly, and high performance and a preparation method thereof. The oil phase of the porous granular ammonium oil explosive of the present invention is composed of (mass%) 88%-94% of hydrogenated heavy oil, 3%-6% of calorific value increasing agent and 3%-6% of antifreezing agent. The porous granular ammonium oil explosive of the present invention has good oil solubility in the oil phase, can add waste mineral oil to realize the reuse of waste oil energy, and has a good environmental protection effect; at the same time, the prepared explosive has excellent blasting performance and low production cost. It is suitable for industrial production and popularization.

Owner:常州市润星化工有限公司 +1

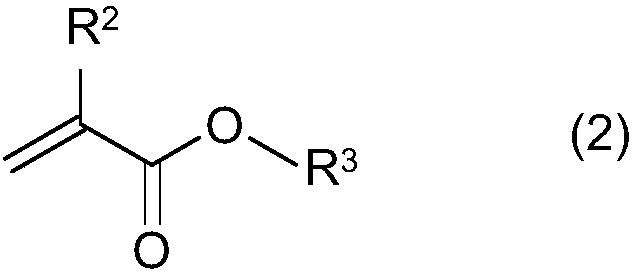

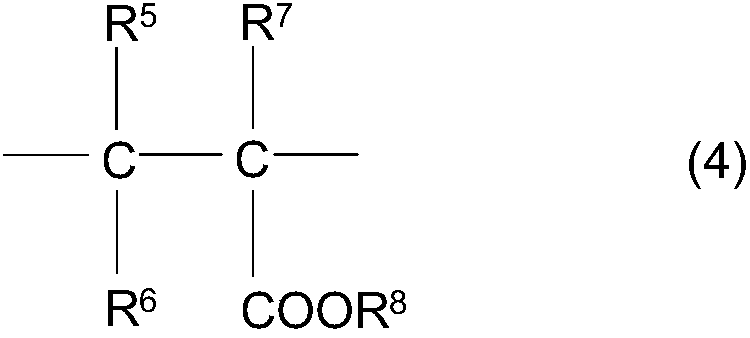

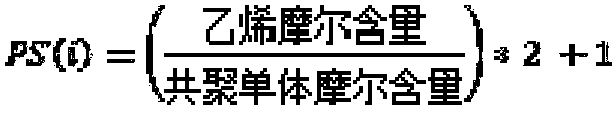

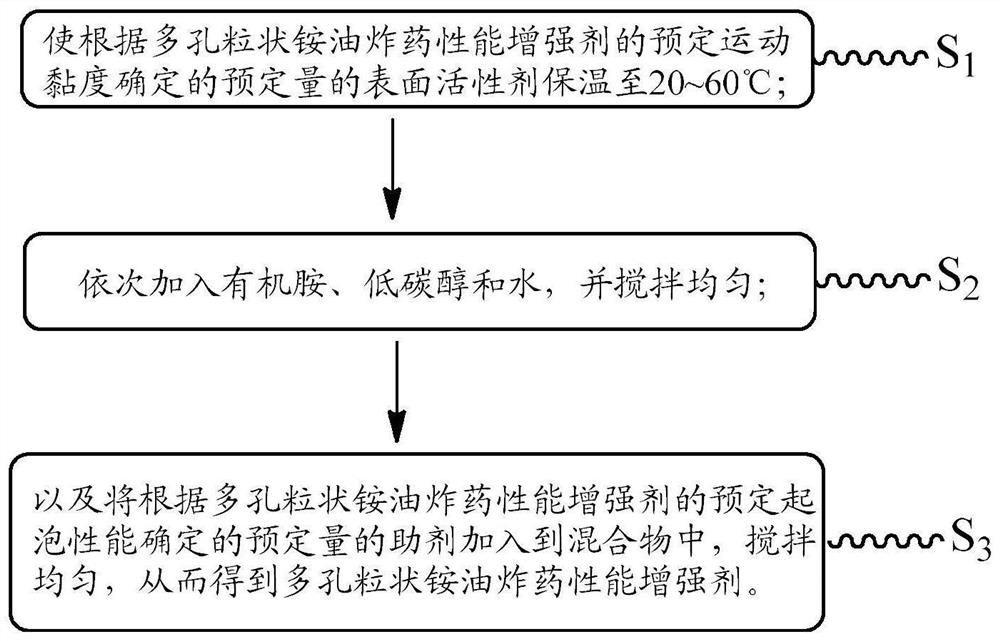

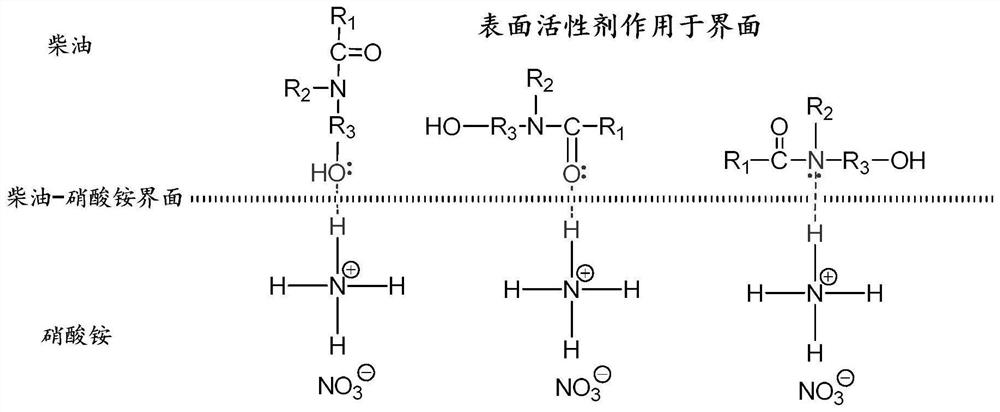

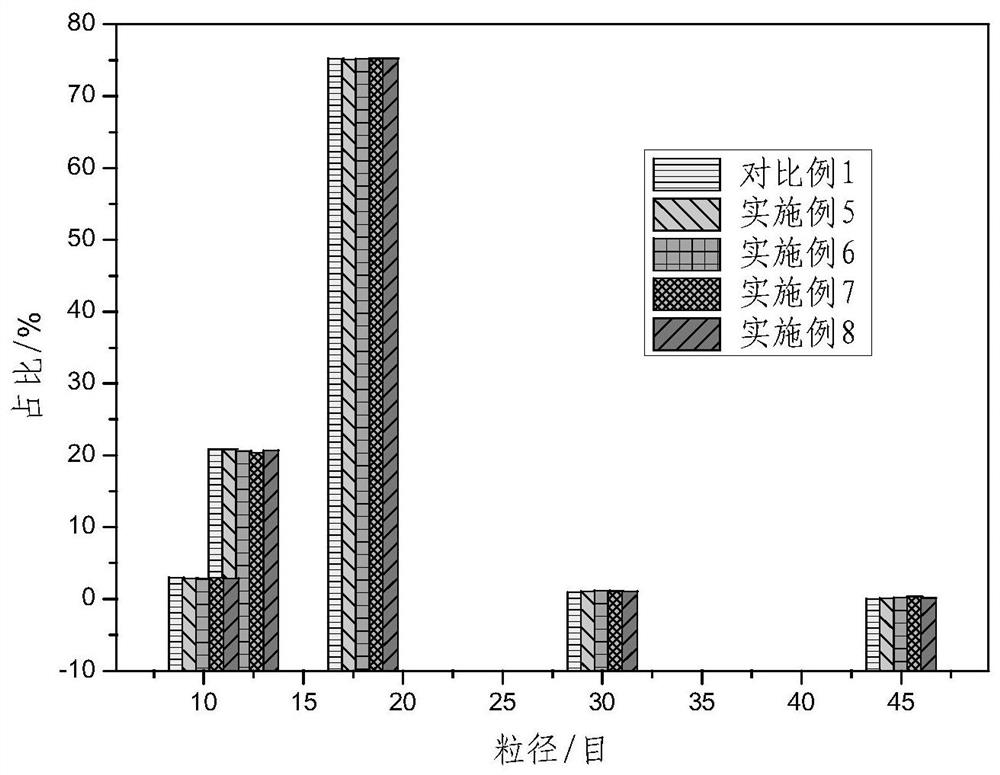

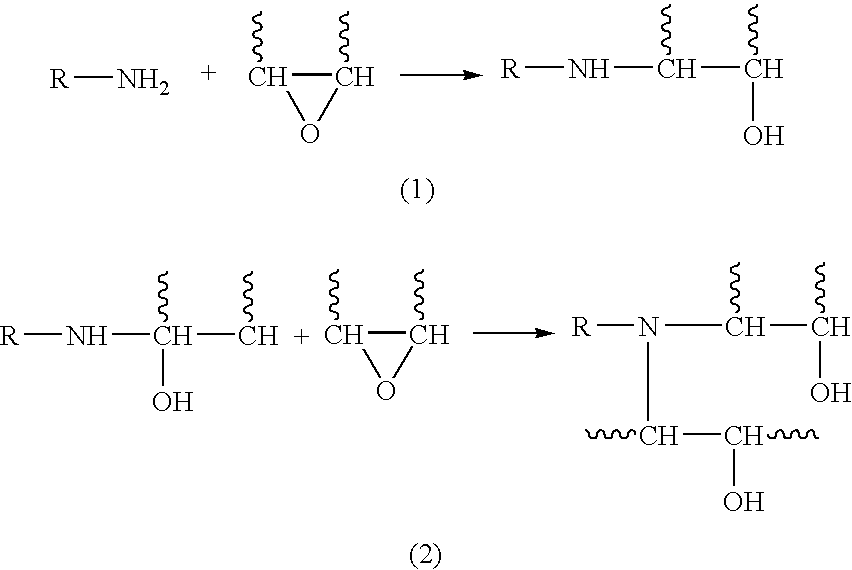

Porous granular ammonium frying medicinal surfactant, performance enhancer and explosive

ActiveCN111875458AReduce interfacial tensionImprove adsorption strengthNon-explosive/non-thermic compositionsExplosive AgentsActive agent

The invention belongs to the field of functional chemicals, and particularly relates to a porous granular ammonium frying medicinal surfactant, a porous granular ammonium frying medicinal performanceenhancer, a preparation method of same, and a porous granular ammonium nitrate fuel oil explosive. The surfactant comprises at least one of compounds represented by a general formula I, a general formula II and a general formula III. The surfactant provided by the invention is further prepared into a performance enhancer for porous granular ammonium nitrate fuel oil explosives, so that the ANFO has excellent detonation performance and storage stability.

Owner:BEIJING BGRIMM YIBO TECH +2

Application of Sudan red for preparing ammonium nitrate fuel oil explosive (ANFO) and corresponding ANFO and preparation method

The invention relates to an application of Sudan red for preparing an ammonium nitrate fuel oil explosive (ANFO), and an ANFO containing the Sudan red and a preparation method thereof. The invention can enable a field operator to visually ensure that the ANFO meeting the formula requirement into each blast hole through a color board, reduces the emission of toxic gas, improves the capacity for work of the explosive, obtains good blasting effect, and meets the requirement of green organization on least content of toxic gas generated after the explosive explodes.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Storage stable ANFO explosive compositions containing chemical coupling agents and method for producing same

An ANFO explosive composition includes a mixture of ammonium nitrate particles, an organic combustible fuel, and a chemical coupling agent having an aliphatic portion and an epoxy group. The chemical coupling agent may be selected from the group consisting of an epoxidized oil, an ester derivative of epoxidized oil and mixtures thereof. The use of such chemical coupling agents and a method of producing the ANFO explosive composition is also disclosed.

Owner:ETI CANADA INC

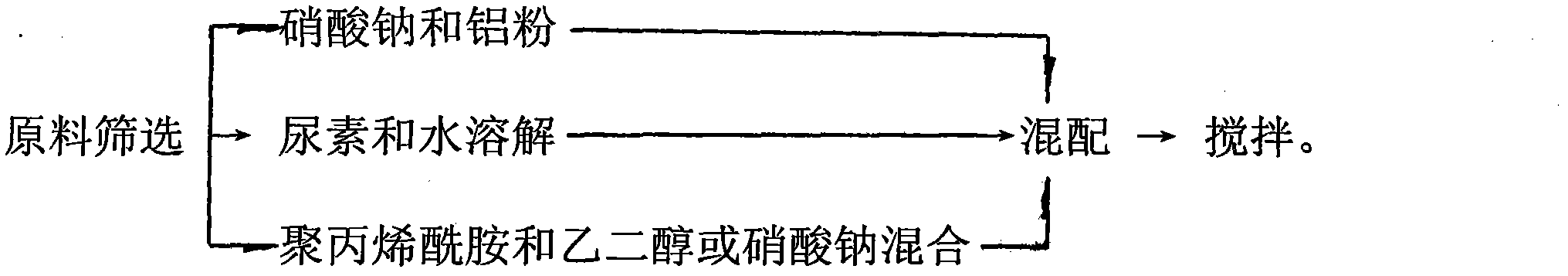

Porous Granular Ammonium Fuel Explosive Binder

ActiveCN102276373ALong storage periodSimple processNon-explosive/non-thermic compositionsAdhesiveANFO

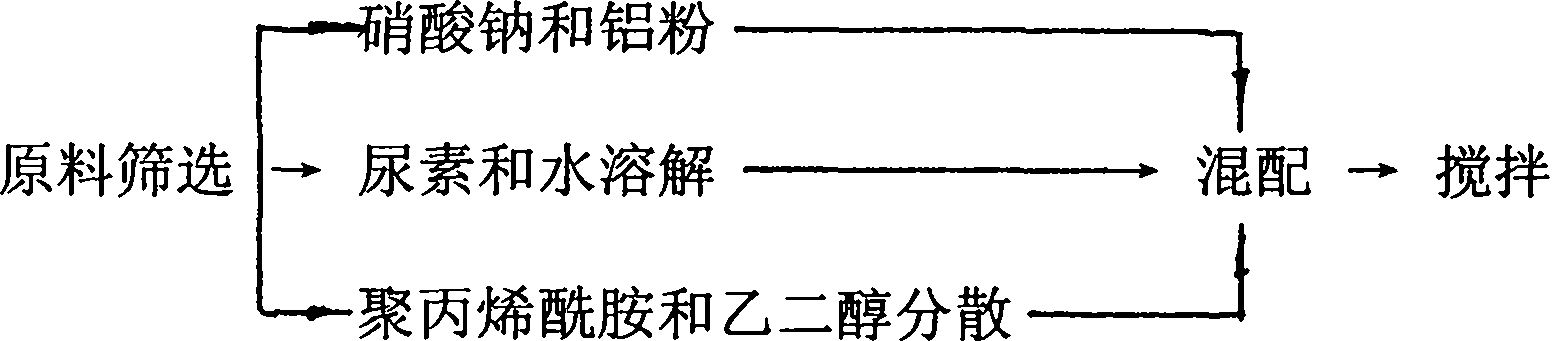

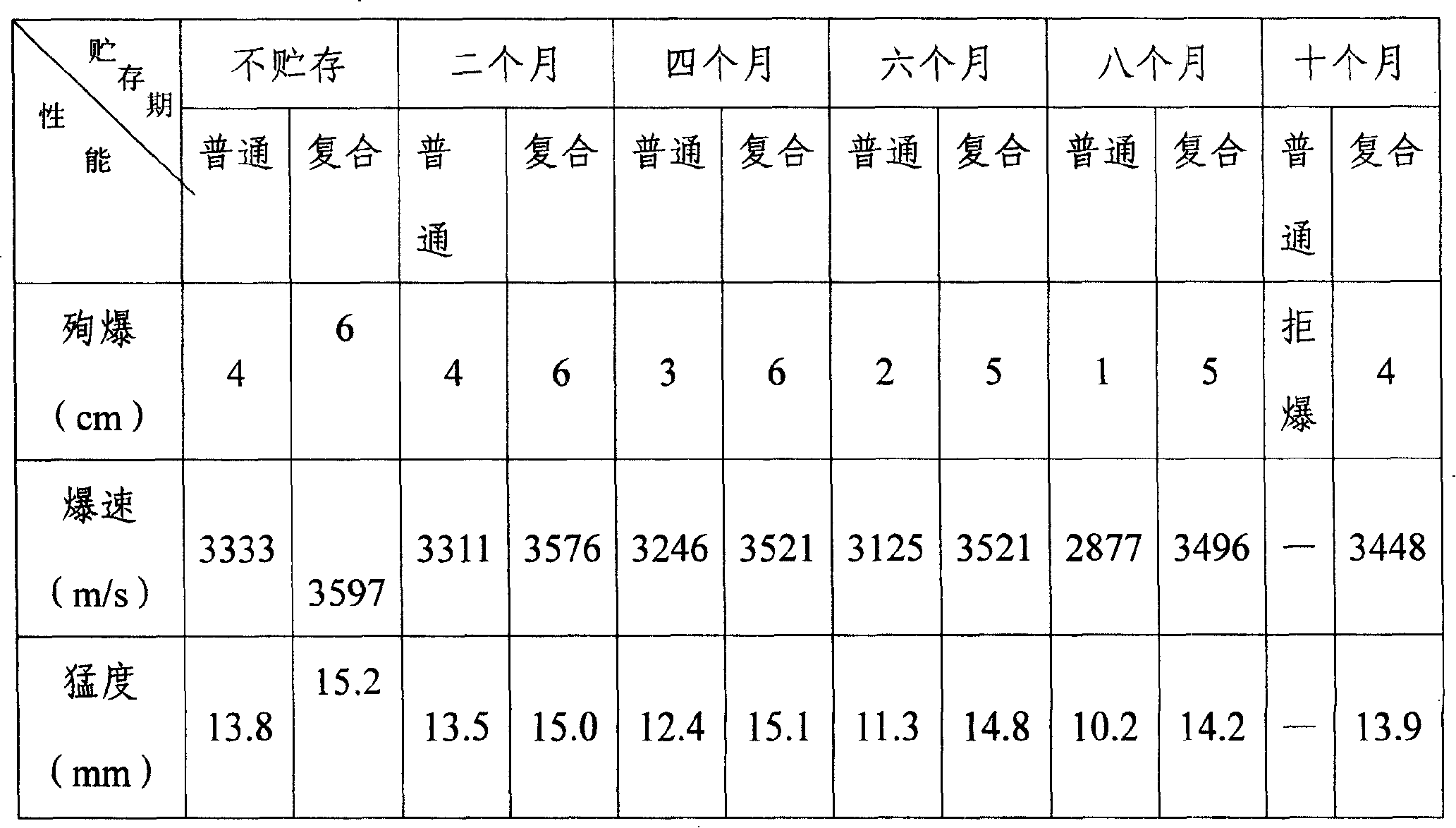

The invention belongs to a porous granular ammonium oil explosive adhesive which is characterized by comprising the following components in percentage by weight: 1.5 to 4 percent of polyacrylamide, 0 to 20 percent of glycol, 10 to 20 percent of urea, 40 to 70 percent of sodium nitrate, 0 to 20 percent of aluminum powder and 10 to 30 percent of water. A method for preparing the porous granular ammonium oil explosive adhesive comprises the following steps of: sieving raw materials, dissolving the urea in the water, dispersing the polyacrylamide and the glycol, mixing, and stirring. In the adhesive, ordinary chemicals are used as the raw materials, dust, toxicity and the pollution of waste water, waste gas and industrial residues are avoided in the production and use process, so the process is simple, investment is small, energy is saved, production cost is low and agglomeration is avoided, and the prepared porous granular ammonium oil explosive does not block the pipe and is not returned and few explosive drops during underground mechanical wind pressure charging, and the explosive has the characteristics of long storage period, namely over six months and environment friendliness, reaches the using standard of the explosive in the prior art and is particularly suitable for operation modes used in mixing sites of mines.

Owner:杨峰 +1

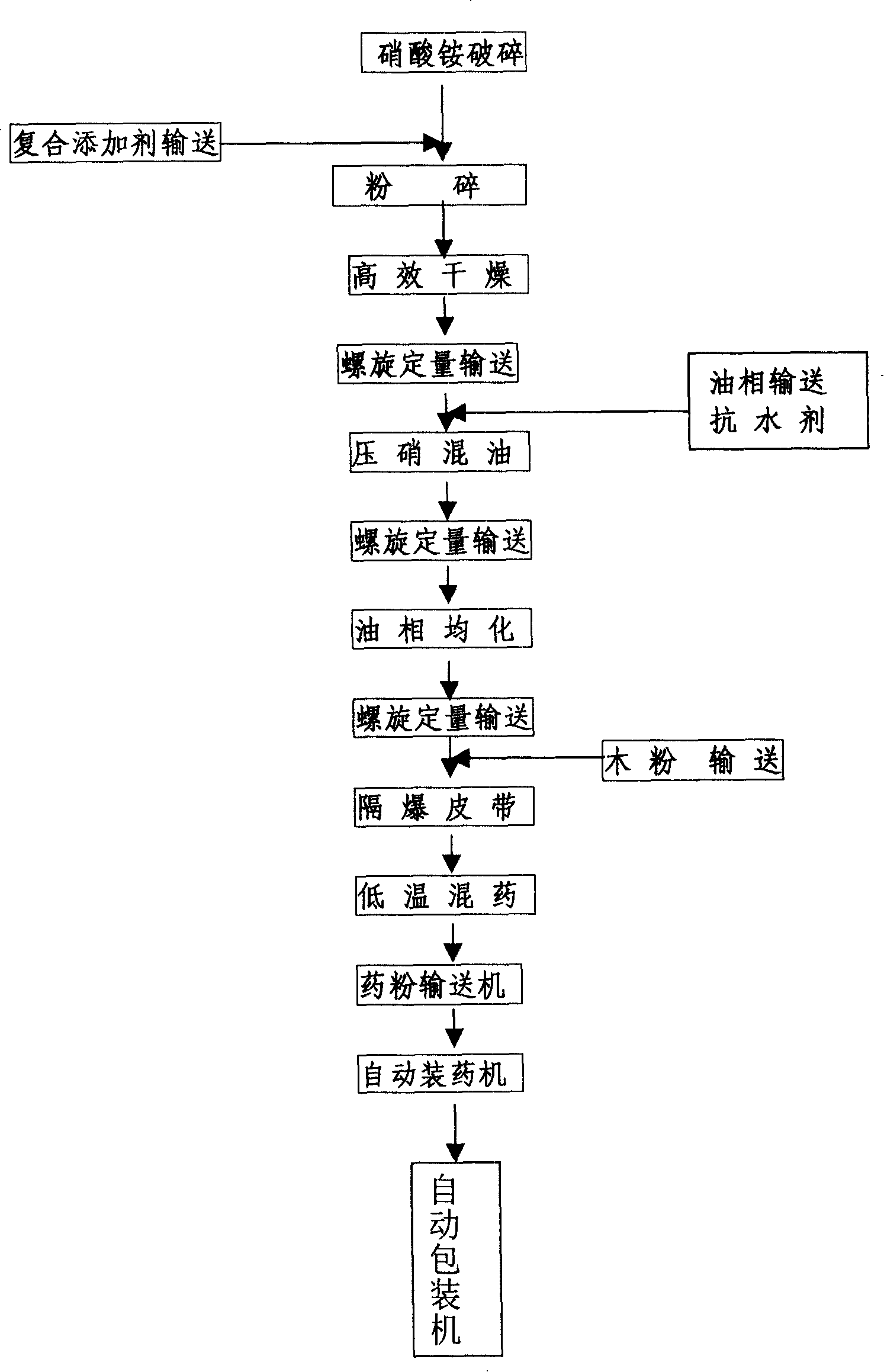

Modified non-TNT powder industrial explosive

The invention discloses a rock-type modified non-TNT powder industrial explosive and a preparation process, the compound additive and waterrepellent agent are arranged into the ammonium nitrate, wood flour and compound oil phase; the compound additive is composed of organic boron surface active agent, 18 hydrochloride, sodium dodecyl sulfate and infiltration powder agent; the raw material is measured according to the proportion, and the powder explosive can be made after the processes of additives mixing, grinding and drying, saltpeter mixed oil pressing, mixed material cooling and explosive packing. The invention is mainly suitable for the continuous automatic production of the non-TNT powder ANFO explosive; whether in a discontinuous production or a continuous production, the compound additive and preparation process of the invention can be adopted to lower the temperature and save energy with environmental protection and safety, furthermore, the product comprising water-resistant explosive has a stronger moisture absorption resistant & water resistant performance, explosion performance and storage performance.

Owner:李新富

Explosive mixtures containing readily gasified additives

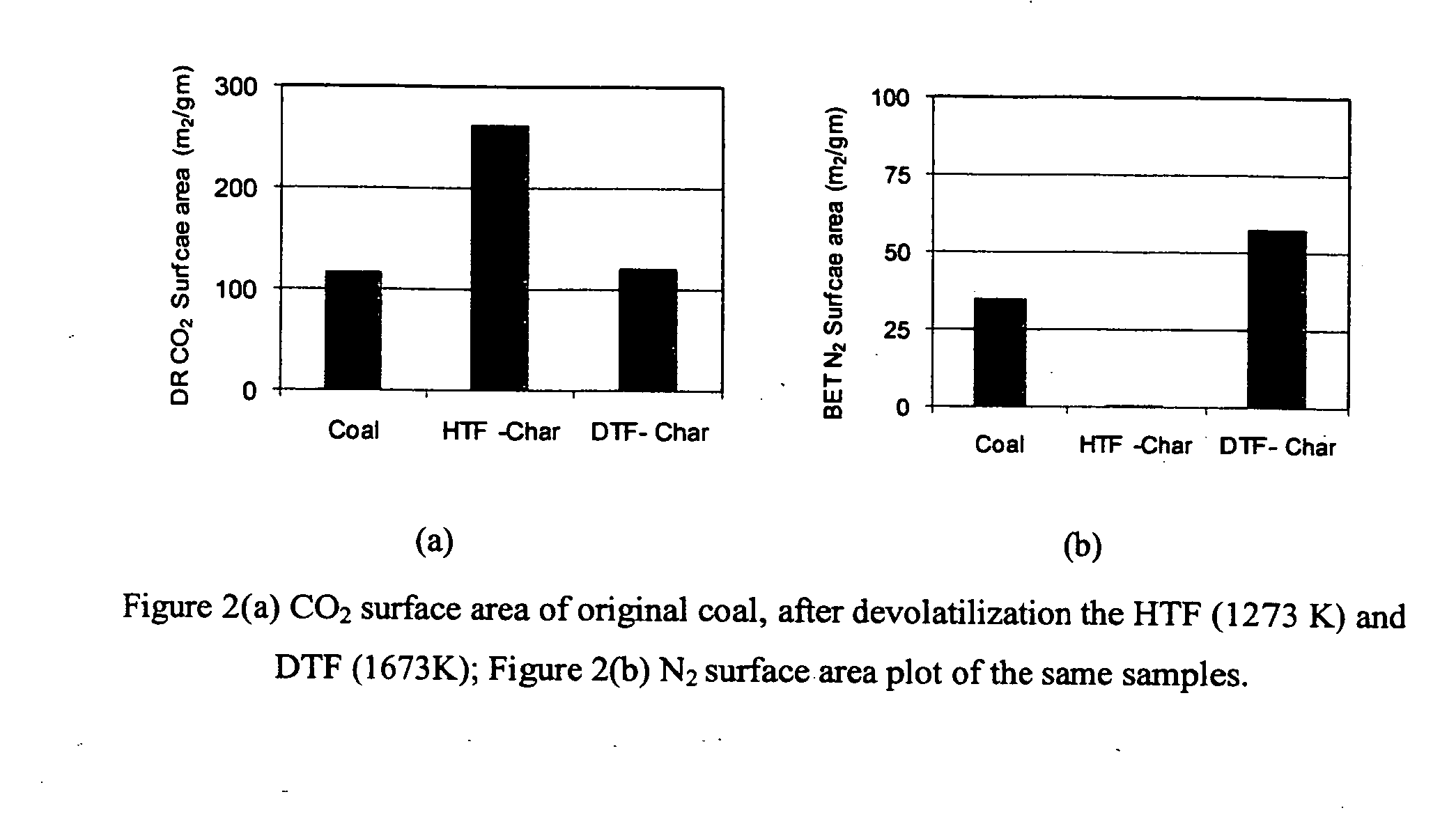

InactiveUS20110114234A1Lower velocity of detonationReduce the formation of nitrogen oxidesLoomsExplosivesPorosityEmulsion

A readily gasified additive has been added to AN (ammonium nitrate) based bulk explosives (ANFO, emulsions, and combinations thereof) with positive results, due to the time, temperature, and pressure conditions generated in a blasthole. The preferred final explosive mixture is primarily comprised of AN, fuel oil, and a carbonaceous additive material that is characterized as being readily gasified as indicated by its rapid release of volatile materials and char formation, the high internal porosity and surface area of the base material and its char, and the uniform distribution of catalytic mineral matter throughout the material. It is understood that other readily gasified additives may be similarly effective.

Owner:FENWICK ANDREW E +3

On-site mixing method and mixing vehicle for surface and underground viscous porous granular ammonium oil explosives

InactiveCN103449941BIncrease stickinessImprove product qualityBlastingExplosive working-up apparatusSoil scienceExplosive Agents

The invention relates to an on-site mixing method and car of a ground and underground viscous porous granular ANFO explosive. A loading platform which is fixed on the ground is adopted, and porous granular ammonium nitrate, composite special oil, a setting agent and a thickener are transported into the loading platform fixed on the ground by manpower through a trolley and are respectively arranged in a porous granular ammonium nitrate storage tank, a composite special oil storage tank, a setting agent storage tank and a thickener storage tank on the on-site mixing car; after that, the on-site mixing car is driven to a blasting site, and viscous porous granular ANFO explosives can be obtained by mixing the porous granular ammonium nitrate, the composite special oil, the setting agent and the thickener; and therefore, the continuity and the automation of the preparation technology can be realized, the manufacturing process is safe and high in reliability, the explosive is good in viscidity, and a product is stable in quality and good in blasting effect. The on-site mixing method and car have the powder charge efficiency of more than 2t / h for a blast hole with phi 70mm, thus being suitable for the blast holes with more than phi 100mm of steps of a surface mine and suitable for powder charging, mining and blasting of an underground tunneling opposite hole and an underground inclined hole blast hole with phi 60-100mm.

Owner:肖代军 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com