On-site mixing method and mixing vehicle for surface and underground viscous porous granular ammonium oil explosives

An ammonium explosive, on-site mixing technology, used in explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of poor dispersion of heavy emulsion explosives, unable to meet the requirements of blasting, and poor viscosity. , to achieve the effect of continuous process, less safety accident and less abnormal situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

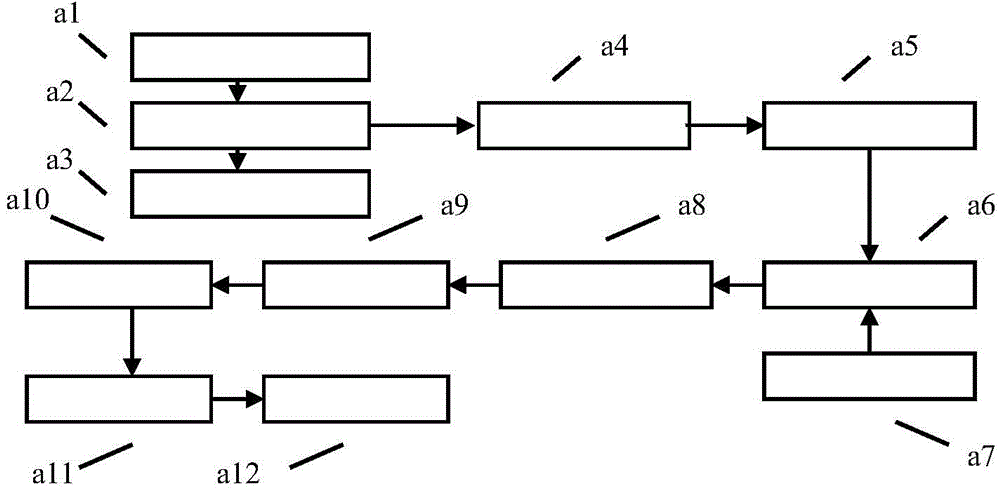

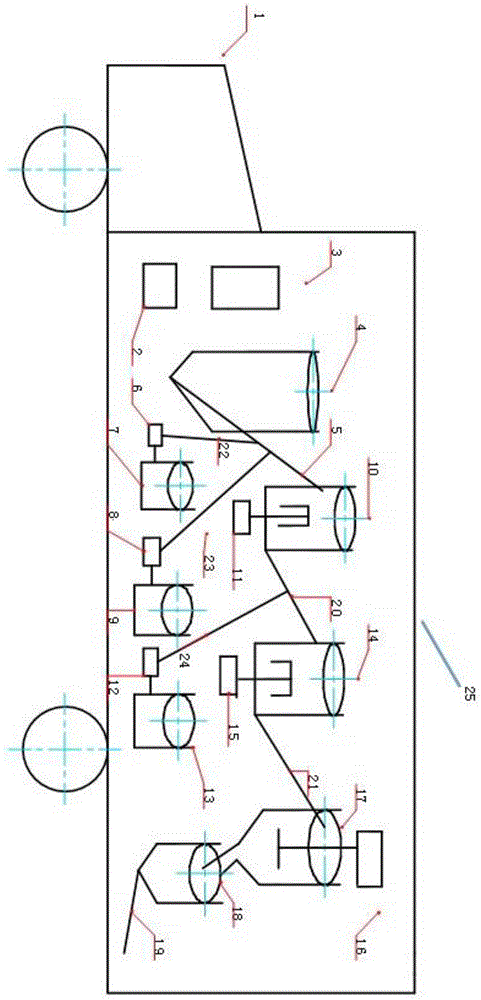

[0047] On-site mixing method of surface and underground viscous porous granular ammonium oil explosives, 360 kg of porous granular ammonium nitrate, 24 kg of compound special oil, 24 kg of setting agent and 20 kg of viscous agent are mixed on site at room temperature, and the porous granular The weight ratio of ammonium nitrate, compound special oil, setting agent and viscous agent is: porous granular ammonium nitrate 83-85, compound special oil 4.5-6, setting agent 3.5-6, viscous agent 3-5, wherein, compound The special oil is made by mixing diesel oil, base oil and emulsifier, the setting agent is made by mixing gypsum powder and polyethylene oxide, and the viscous agent is made by mixing water, polyvinyl alcohol, polyacrylamide, polyethylene oxide and urea; The method comprises the following steps in sequence:

[0048] A. Transport the porous granular ammonium nitrate, compound special oil, setting agent and viscous agent from the warehouse to the loading and unloading plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com