Porous granular ammonium frying medicinal surfactant, performance enhancer and explosive

A technology of surfactant and ammonium explosive, applied in the field of functional chemicals, can solve the problems of low detonation performance of explosives, uneven mixing, slow mixing rate of porous granular ammonium nitrate and diesel oil, etc. Improves and reduces the production of smoke and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

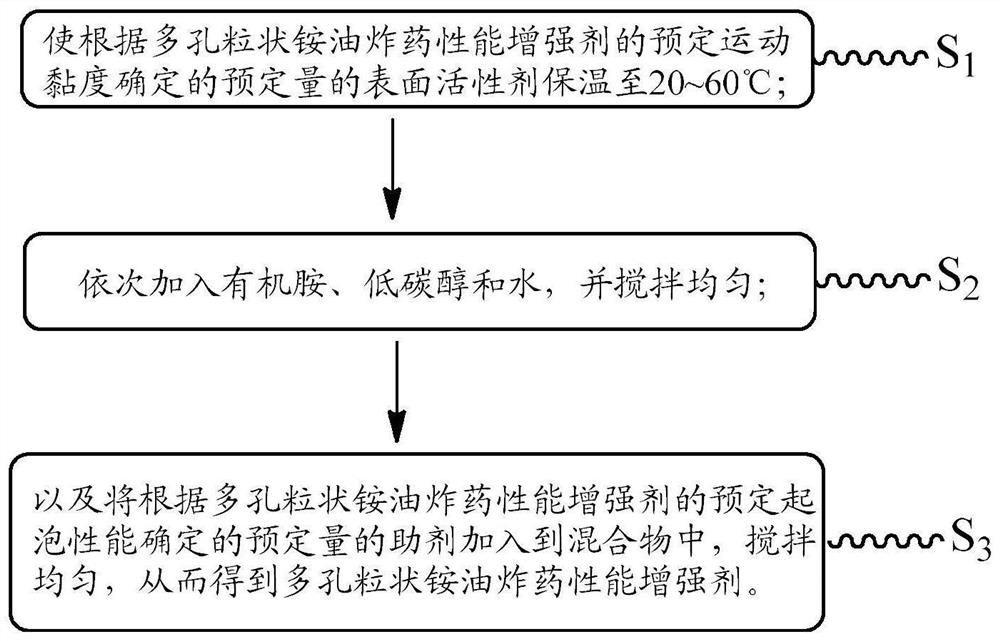

Method used

Image

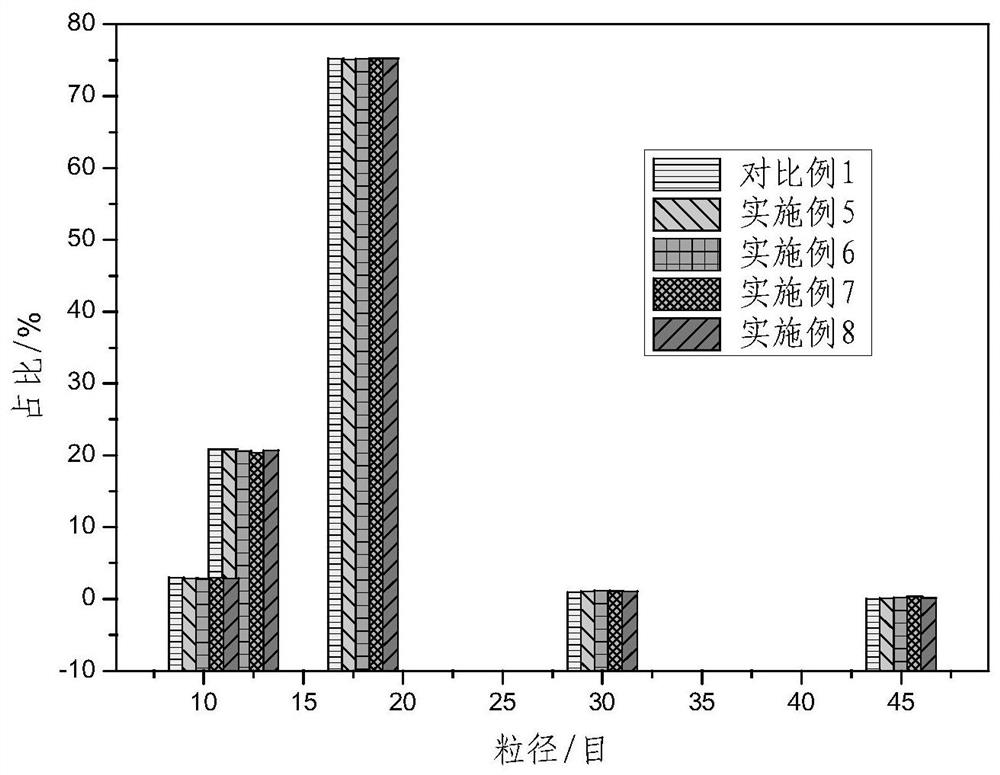

Examples

Embodiment 1

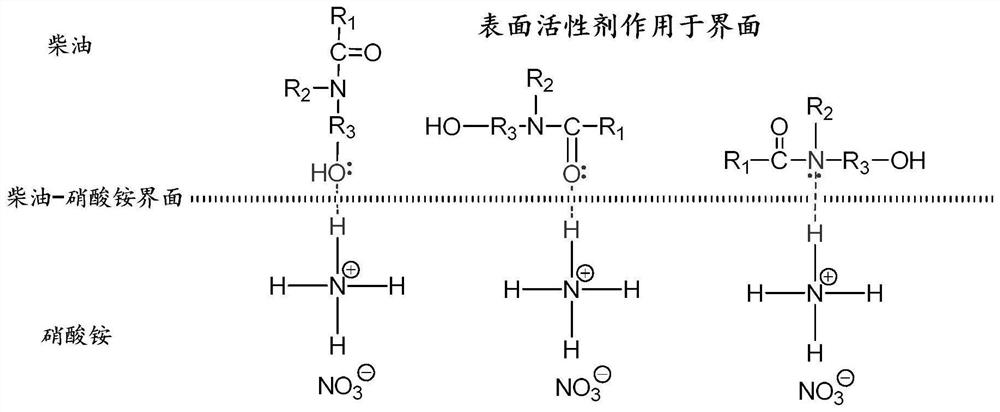

[0066] Preparation of Example 1 Porous Granular Ammonium Oil Explosive Performance Enhancer ANFO-Add-1

[0067] Preparation of lauric acid diethanolamide: Add 105g of diethanolamine and 1g of sodium hydroxide to a 500mL three-necked flask equipped with a thermometer, mechanical stirring, water separator and condenser, stir well and heat up to 150°C, then within 3h After adding 215g of methyl laurate dropwise, the methanol generated by the reaction was continuously distilled off during the reaction, and then the reaction was continued for 0.5h, cooled to room temperature, and the obtained crude product was recrystallized from absolute ethanol to obtain a white product: diethyl laurate Amide, CH 3 (CH 2 ) 10 CON(CH 2 CH 2 Oh) 2 .

[0068] Heat 4.9 parts by weight of the above-mentioned lauric acid diethanolamide to 55°C and melt, then add 0.5 parts by weight of triethylamine, 20.0 parts by weight of ethanol, 74.5 parts by weight of deionized water and 0.1 parts by weight o...

Embodiment 2

[0069] Preparation of Example 2 Porous Granular Ammonium Oil Explosive Performance Enhancer ANFO-Add-2

[0070] Preparation of triethanolamine stearate: In a 500mL three-necked flask equipped with a thermometer, mechanical stirring, water separator and condenser, add 227g of stearic acid to heat up and melt, then add 1g of p-toluenesulfonic acid, then dropwise add 120g of triethanolamine , after constant stirring, the temperature was raised to 180°C, the reaction was kept for several hours and the water generated by the reaction was continuously distilled off. When the acid value of the reaction system drops to 3mgKOH g-1, stop the reaction and cool to room temperature to obtain a light yellow waxy product: triethanolamine stearate, CH 3 (CH 2 ) 16 COOCH 2 CH 2 N(CH 2 CH 2 Oh) 2 .

[0071] Heat 4.9 parts by weight of triethanolamine stearate to 50°C to melt, and then add 0.5 parts by weight of triethylamine, 20.0 parts by weight of methanol, 74.5 parts by weight of dei...

Embodiment 3

[0072] Example 3 Preparation of Porous Granular Ammonium Oil Explosive Performance Enhancer ANFO-Add-3

[0073] Preparation of oleic acid triethanolamine salt: Add 225.6g of oleic acid into a 500mL three-neck flask equipped with a thermometer, mechanical stirring, and condenser tube, add 120g of triethanolamine dropwise at room temperature, and keep stirring to obtain a light yellow viscous oily product: oleic acid Triethanolamine salt, [CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COO - ][N + (CH 2 CH 2 Oh) 3 ].

[0074] Heat 5.0 parts by weight of oleic acid triethanolamine salt to 45°C, add 0.5 parts by weight of triethylamine, 20.0 parts by weight of ethanol, and 74.5 parts by weight of deionized water successively under constant stirring, and continue stirring for several minutes to obtain clarification Transparent porous granular ammonium oil explosive performance enhancer ANFO-Add-3. The content of each component is shown in Table 2, and the corresponding performance test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com