Modified ammoium nitrate fuel oil (ANFO) explosive and preparing method thereof

An ammonium oil explosive and modification technology, which is applied in the direction of explosives, etc., can solve problems such as the shortage of combustible agent resources, and achieve the effects of avoiding recrystallization, improving physical properties, and improving storage and explosive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

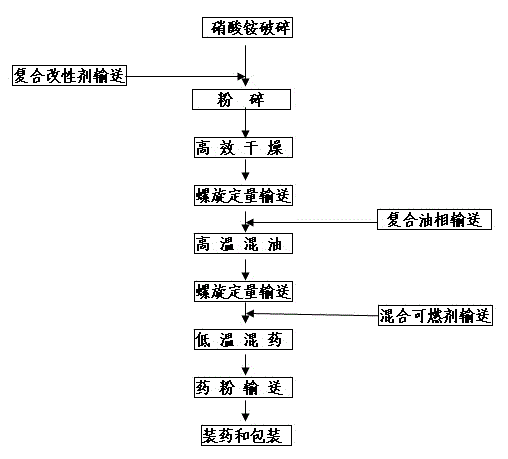

Method used

Image

Examples

Embodiment 1

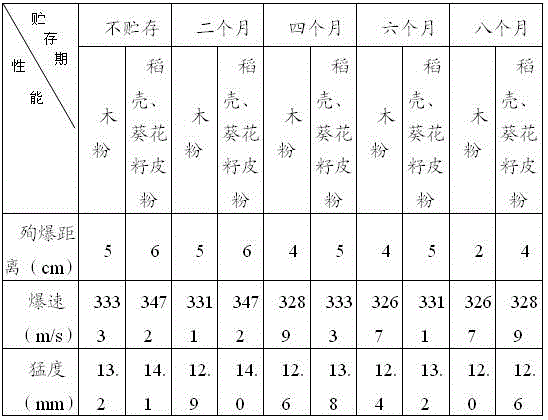

[0030] Process ratio: 91.7 wt% ammonium nitrate, 0.3 wt% composite modifier, 4.0 wt% composite oil phase, 1.0 wt% rice husk powder, and 3.0 wt% sunflower seed hull powder.

[0031] 1) 91.7% by weight of ammonium nitrate and 0.3% of the total weight of the raw materials are mixed and pulverized, and dried at 80°C-95°C until the water content is not more than 0.2%.

[0032] 2) Add compound oil phase accounting for 4.0% of the total weight of the raw material to the dry material and mix evenly, and the temperature is controlled at 80°C-95°C;

[0033] 3) Mix evenly with rice husk powder accounting for 1.0% of the total weight and sunflower seed hull powder accounting for 3.0% of the total weight, and after the moisture meets the requirements, send it to the explosive cold mixer. After the materials are evenly mixed and the temperature drops below 40°C Out of the material, the moisture content of the powder is not more than 0.3%.

Embodiment 2

[0035] Process ratio: 91.5 wt% ammonium nitrate, 0.3 wt% composite modifier, 3.7 wt% composite oil phase, 1.5 wt% rice husk powder, and 3.0 wt% sunflower seed hull powder.

[0036] 1) Mix and pulverize 91.5% ammonium nitrate by weight percentage with 0.3% composite modifier accounting for the total weight of raw materials, and dry at 80°C-95°C until the moisture content is no more than 0.2%;

[0037] 2) Add a compound oil phase accounting for 3.7% of the total weight of the raw material to the dry material and mix evenly, and the temperature is controlled at 80°C-95°C;

[0038] 3) Mix evenly with rice husk powder accounting for 1.5% of the total weight and sunflower seed hull powder accounting for 3.0% of the total weight, and after the moisture meets the requirements, send it to the explosive cold mixer. After the materials are evenly mixed and the temperature drops below 40°C Out of the material, the moisture content of the powder is not more than 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com