Modified non-TNT powder industrial explosive

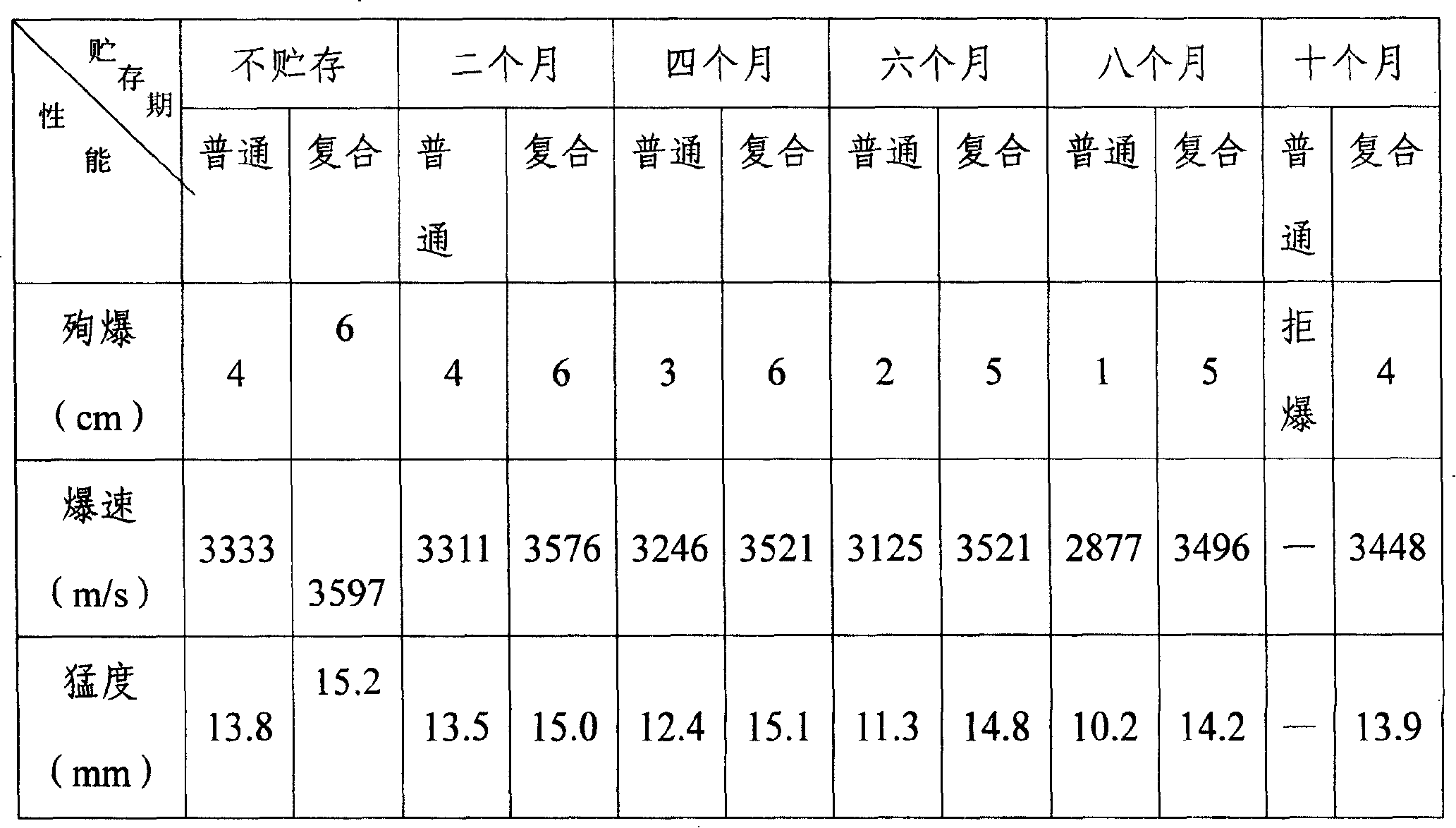

An industrial explosive and powdery technology, which is applied in the direction of explosives, etc., can solve the problems of high cost, poor safety, and low detonation sensitivity of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: (water-resistant explosive)

[0022] 1. The weight ratio of explosive raw materials and compound additives:

[0023] 1. Raw materials: 92.4% of ammonium nitrate, 4% of wood flour, 3.0% of composite oil phase (manufacturer: Jinxi Petrochemical Company), 0.6% of water resistant agent (wherein asphalt and paraffin are each 0.3%), and the sum of raw materials is 100%.

[0024] 2. The compound additive is 0.3% of the total amount of raw materials, wherein the percentage by weight of each component of the additive is:

[0025] Recipe 1: Boric Acid Diglycerol C 12 -C 22 Fatty acid ester (produced by Beijing Research Institute of Chemical Industry) 20%, stearylamine 49%, sodium lauryl sulfate 8%, talcum powder 23%.

[0026] Recipe 2: Boric Acid Diglycerol C 12 -C 22 Fatty acid ester 22%, stearylamine 48%, sodium lauryl sulfate 9%, talc 21%.

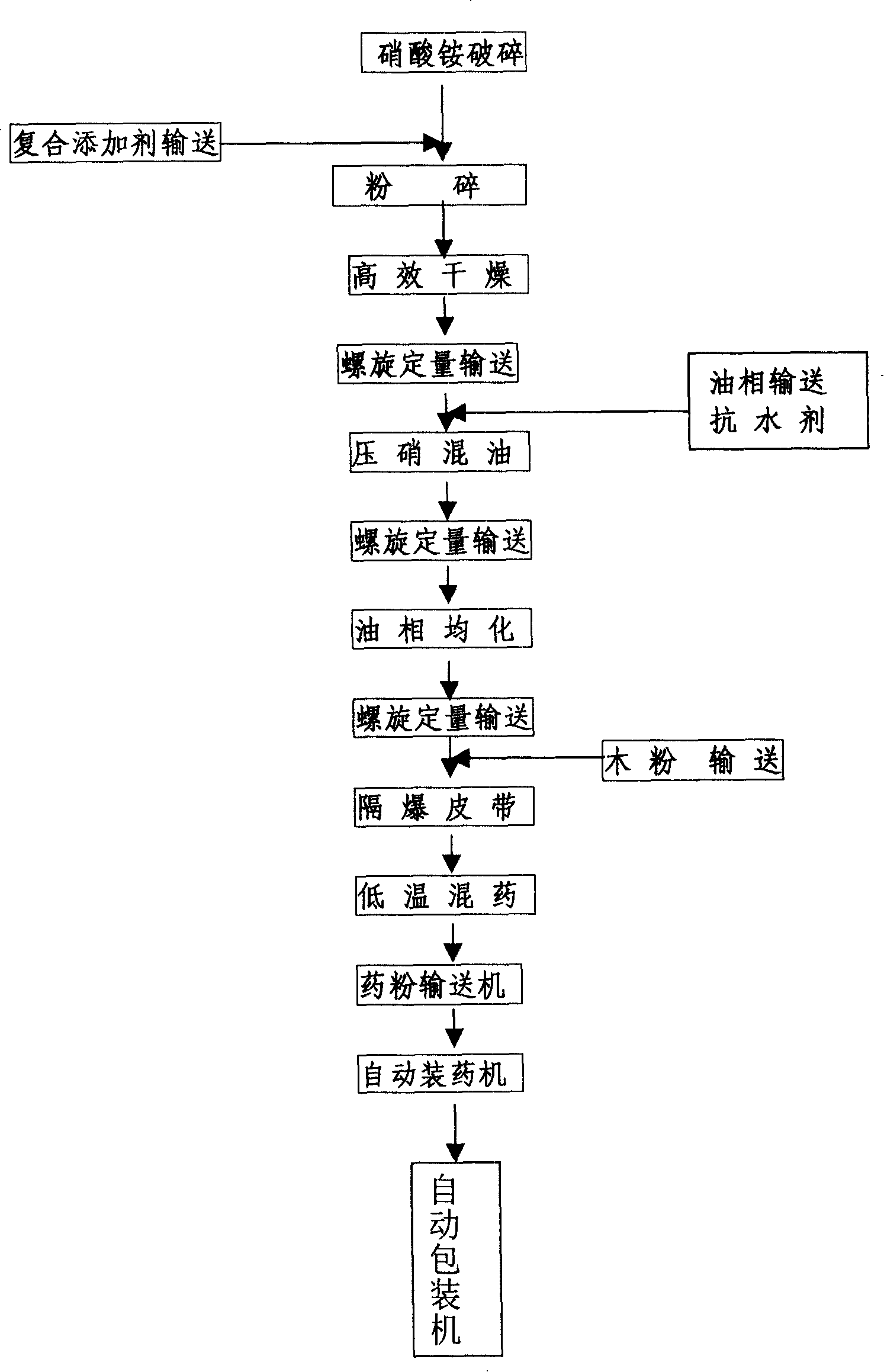

[0027] 2. Preparation process

[0028] 1. Preparation of compound additives

[0029] According to the above ratio, ...

Embodiment 2

[0032] Embodiment 2: (modified rock type explosive)

[0033] 1. The weight ratio of explosive raw materials and compound additives:

[0034] 1. Raw materials: 92.1% of ammonium nitrate, 4.3% of wood powder, 3.6% of composite oil phase, and the sum of raw materials is 100%.

[0035] 2. The compound additive is 0.3% of the total amount of raw materials, wherein the percentage by weight of each component of the additive is:

[0036] Recipe 1: Boric Acid Diglycerol C 12 -C 22 20% fatty acid ester, 50% octadecylamine, 9% sodium lauryl sulfate, 21% diatomaceous earth.

[0037] Recipe 2: Boric Acid Diglycerol C 12 -C 22 Fatty acid ester 18%, stearylamine 53%, sodium lauryl sulfate 8%, diatomaceous earth 21%.

[0038] 2. Preparation process

[0039] 1, the preparation of composite additive (method is with embodiment 1).

[0040] 2. Preparation of rock-type explosives

[0041] Mix and crush ammonium nitrate and compound additives according to the above ratio, so that more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com